¶ Tools and Materials

- A 2.0 mm Allen wrench

- A 2.5 mm Allen wrench

- A 4.0 mm Allen wrench

- A New X-axis motor

¶ Tutorial Video

¶ Instruction

- Power off the printer and unplug the power cord.

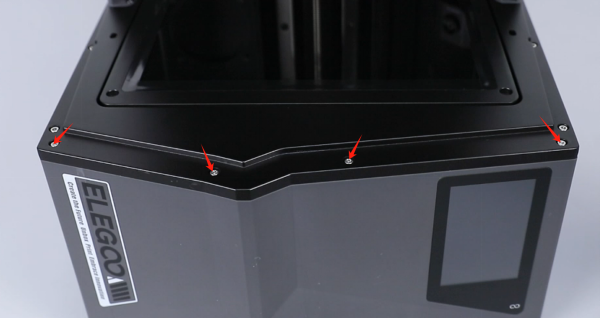

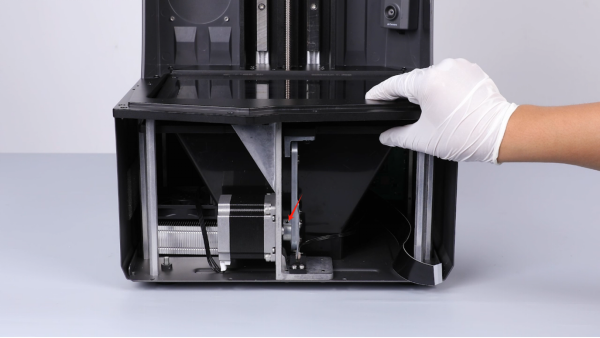

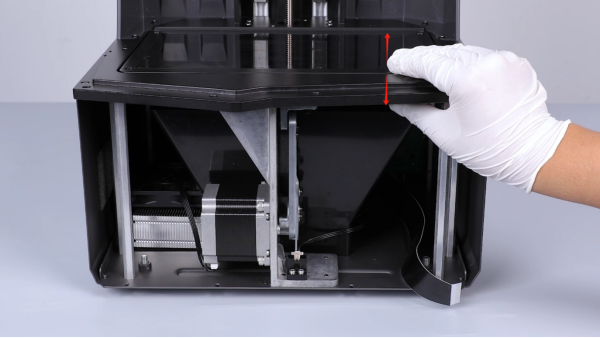

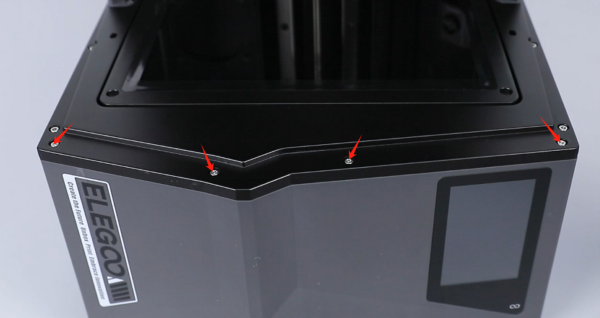

- Lift the top cover. Use a 2.5 mm Allen wrench to loosen the 4 screws fixed at the upper part of the front cover.

- Close the top cover and put the printer on its side. Use a 2.5 mm Allen key to loosen the 4 screws fixed at the lower part of the front cover.

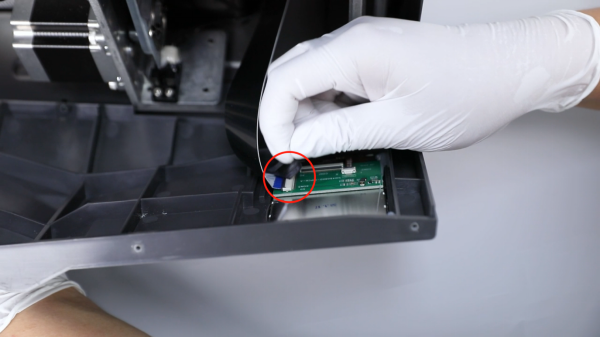

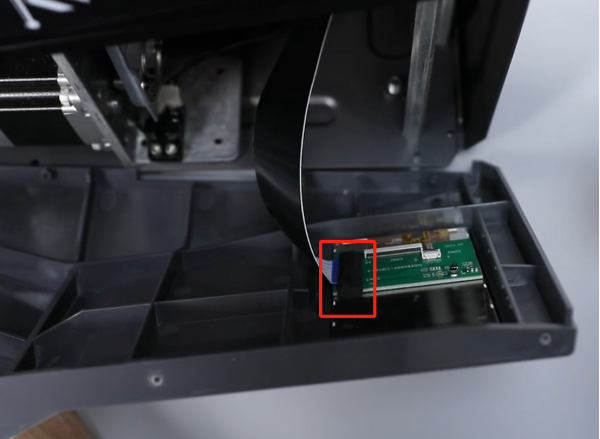

- Open the front cover a little slit, remove ribbon cables of the the touchscreen port, and take out the front cover.

Note: There are ribbon cables inside. Take care to remove the cover.

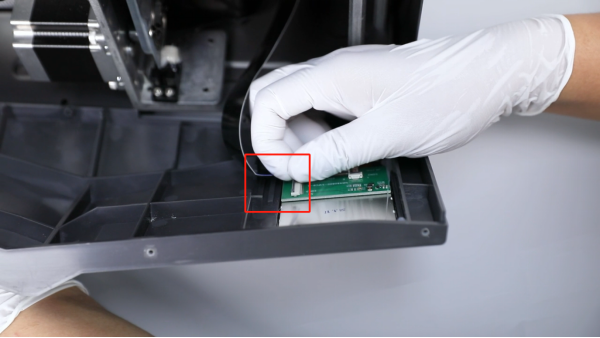

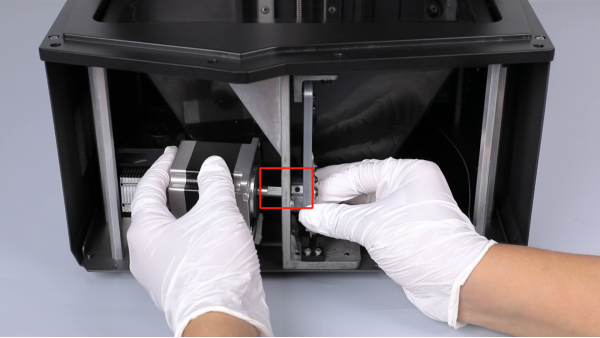

- Disconnect the ribbon cables of the X-axis motor port.

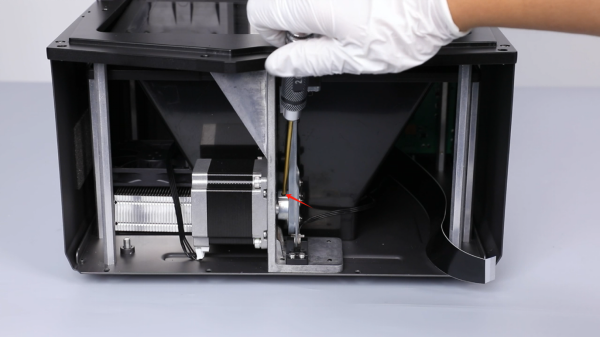

- Rotate the X-axis and turn the fixing screws of the rotating axis forward.

- Use a 2.0 mm Allen wrench to loosen the screw securing the rotating axis.

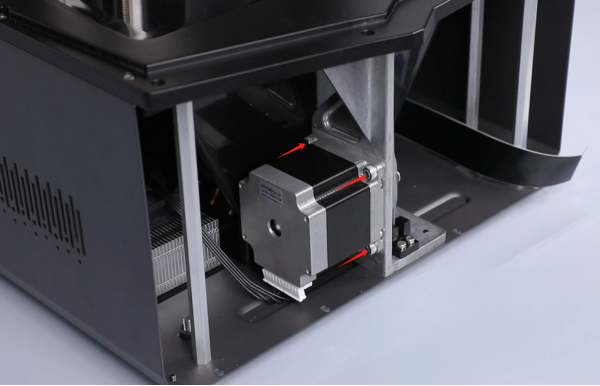

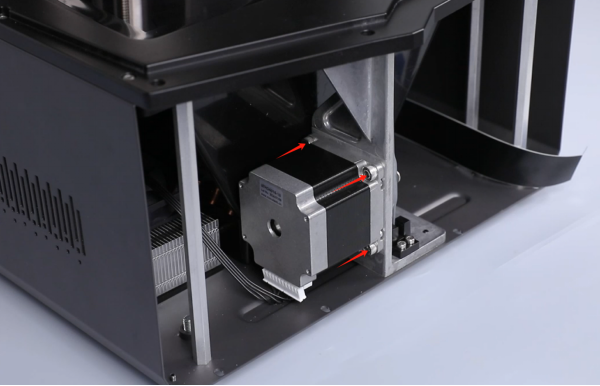

- Use a 4.0 mm Allen wrench to loosen the 4 screws securing the X-axis motor. Remove the old X-axis motor.

- Prepare the new X-axis motor, rotate the front lever of the motor to align the cutting surface with the screw mounting position.

- Put the X-axis motor in the installation position by aligning it the the screw holes.

- Use a 4.0 mm Allen wrench to tighten the 4 screws securing X-axis motor several times.

Note: It is suggested to tighten the screws several times.

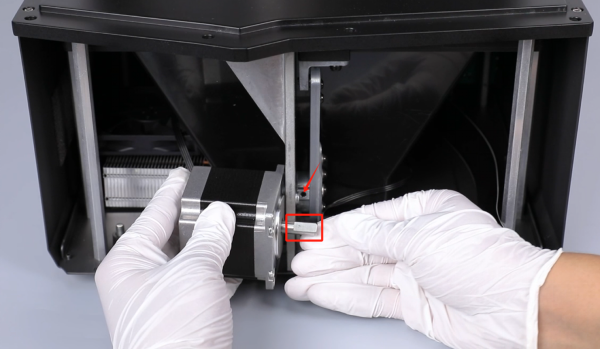

- Ensure that the front of the motor lever aligns with the side surface of the rotating axis of the X-axis. Use a 2.0 mm Allen key to tighten the screw securing the rotating axis.

- Insert the ribbon cables of the X-axis motor.

- Tilt the LCD screen manually to ensure that there is no lag.

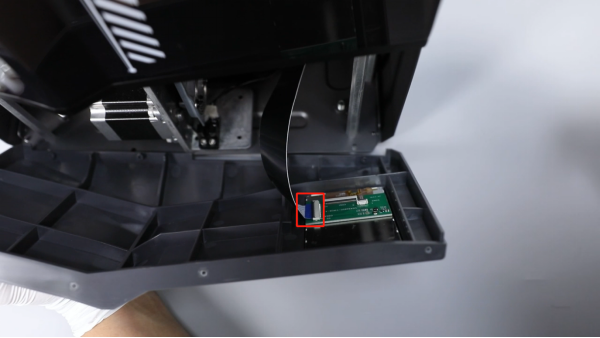

- Prepare the front cover. Insert the ribbon cables of the touchscreen into the touchscreen port and stick the black tape to the port of the touchscreen ribbon cables.

Note: The touchscreen ribbon cables have a fixed installation position.

- Put the front cover in the installation position by aligning it with the screw holes. Use a 2.5 mm Allen wrench to tighten the 4 screws securing the upper and lower part of the front cover.

- Power on the printer. The printer is ready for use after its self-inspection.