¶ Tools and Materials

- A 2.5 mm Allen key

- A4 paper

¶ Tutorial Video

¶ Instruction

This guide will take you through the fine-tuning of the build plate after the automatic leveling.

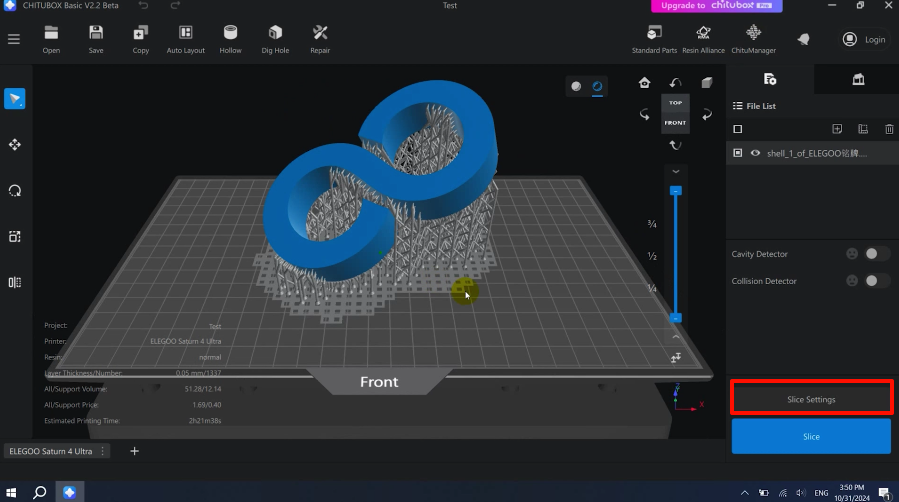

- Import the model file into the slicing software. Click "Slice Settings".

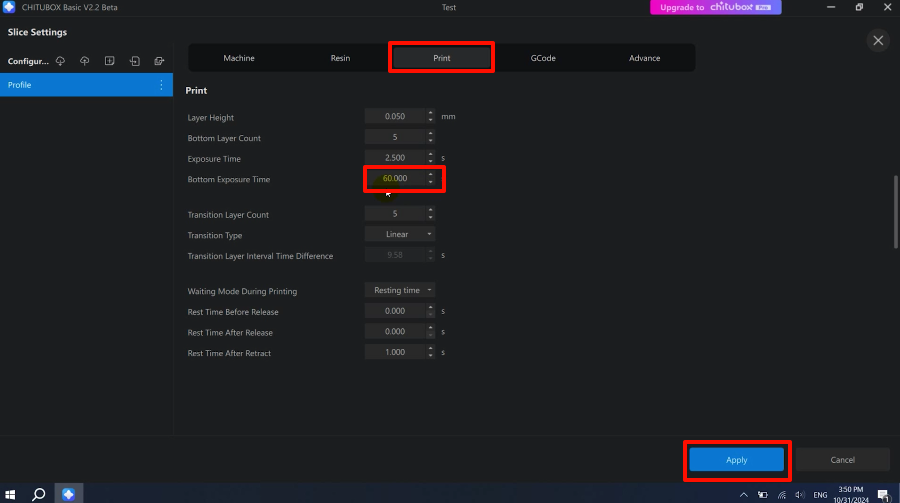

- Click "Print". In the parameter setting interface, set the "Underlying Exposure Time" parameter to 60s (or 90s). Click "Apply" to save the modified parameters.

Note: Set the bottom exposure time longer to allow more time to adjust the screws later.

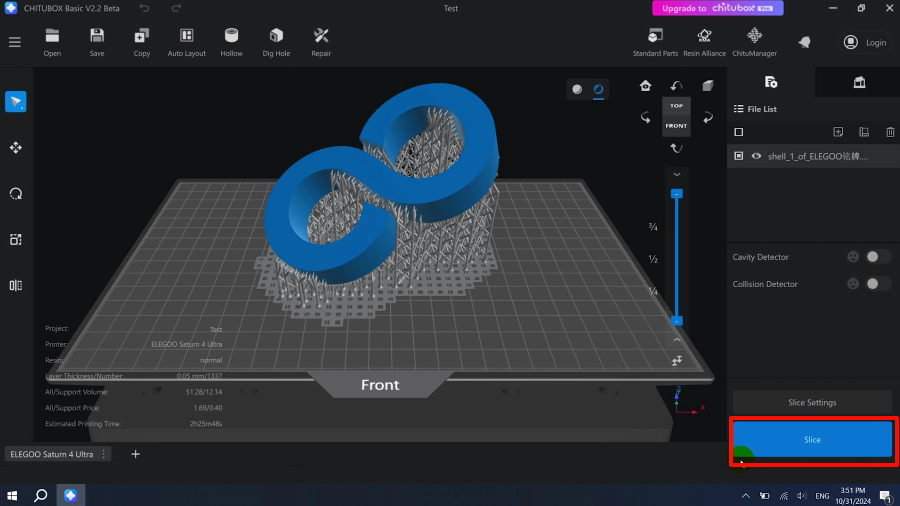

- Click "Slice" and save the sliced file to the USB flash drive.

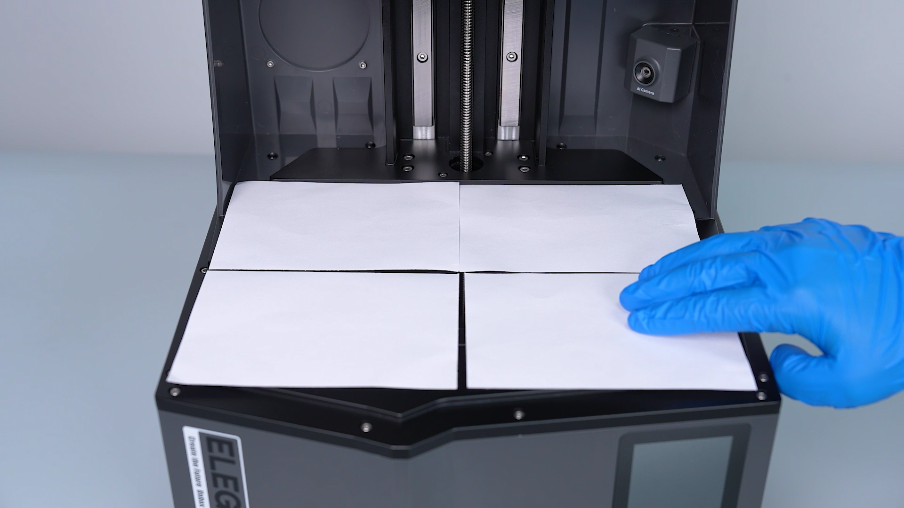

- Tear a piece of A4 paper into 4 equal pieces and place them at the four corners of the LCD screen.

- Power on the printer. Plug in the USB flash drive. On the touchscreen, click "Print - USB File". Select the model to print.

Note: The model is printed without the resin tank.

- If a "Print Abnormal" pop-up window appears, click "Mandatory Printing". The touchscreen shows that the automatic leveling is completed. The printer will start printing the model.

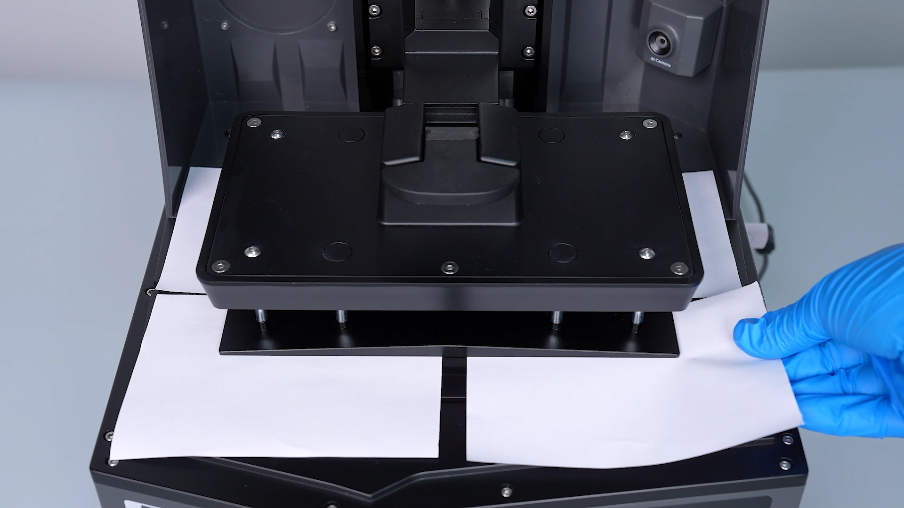

- During the printing of the first layer of model exposure, pull the A4 paper in the four corners and observe which corner of the paper is obviously loose.

Note: The pressed state refers to that the paper can be pulled out under the print platform, but cannot be pushed back.

- For the paper that is loose at the corner, loosen the screw at that corner counterclockwise slightly using a 2.5mm Allen key.

Note: Loosen the screw slightly. It is forbidden to tighten the screws drastically to prevent abnormalities of the build plate.

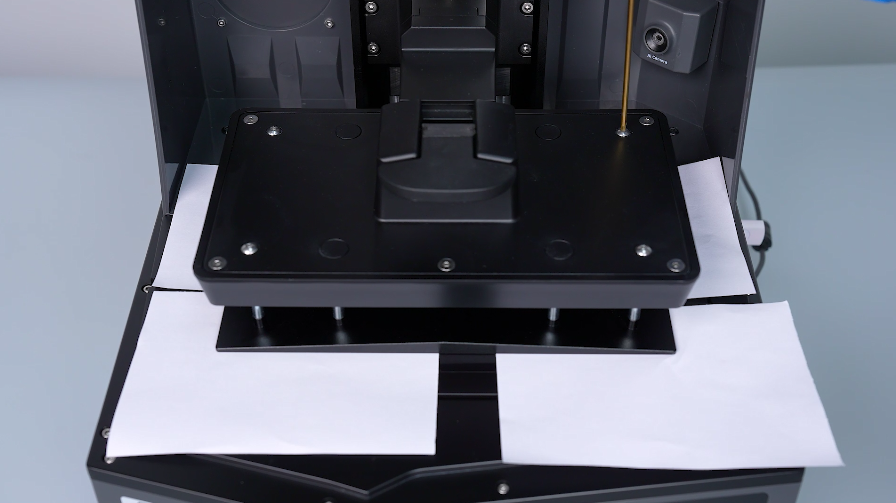

- After adjusting the screws, pull the 4 pieces of paper in the corner of the build plate again to test the tightness. Make sure that the paper is fully pressed and the fine-tunning is completed.

Note: After adjusting either screw, the paper at the four corners needs to be re-tested for tightness.