¶ Reference video

¶ XY axis timing belt connection method

X-axis

Y-axis

¶ When to replace

- The timing belt is broken

- The timing belt is aged or worn and has affected its function.

¶ Tools and materials needed

- 2.0 mm Allen wrench X 1

- 2.5 mm Allen wrench X 1

¶ Precautions before operation and machine status

Turn off the power and remove the power cord.

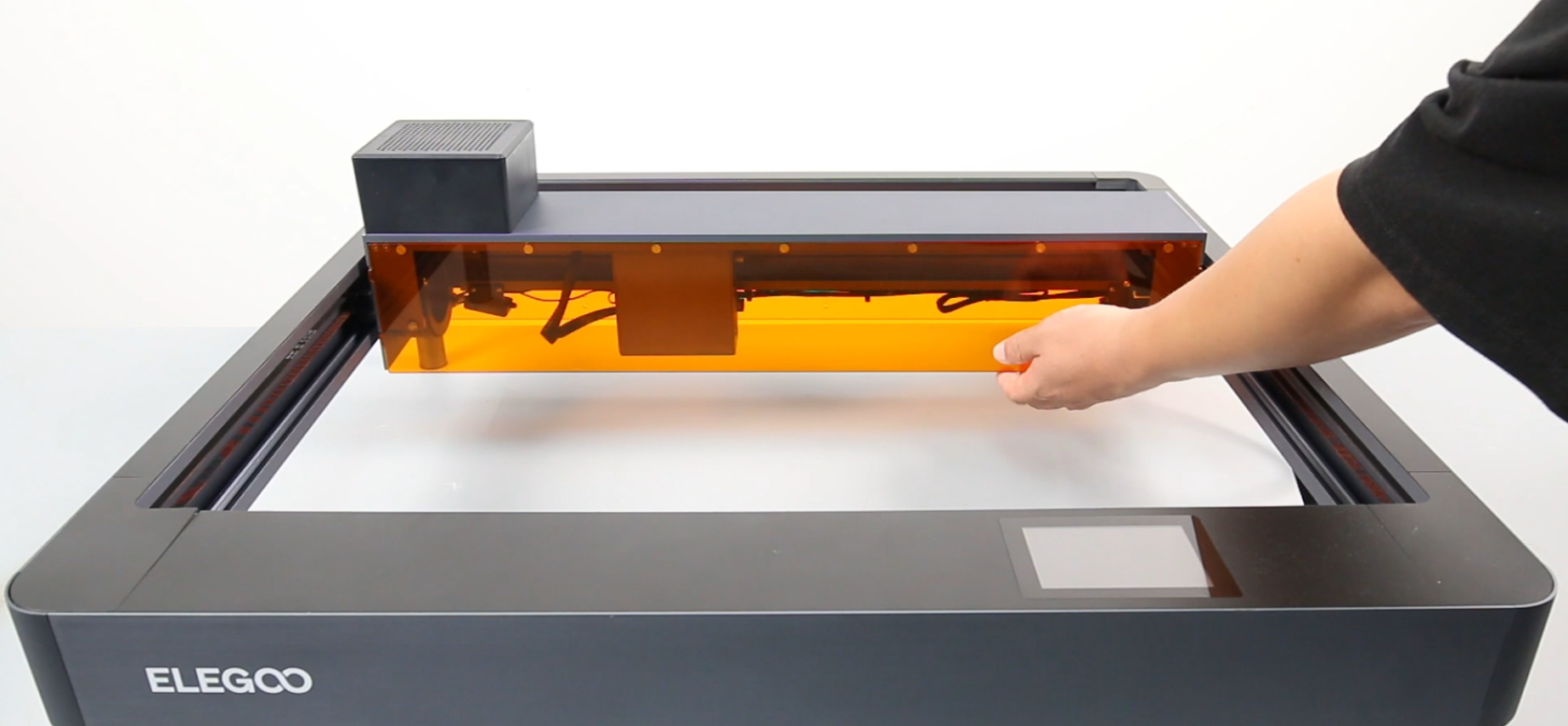

¶ Operation guide: Replacing the X-axis timing belt

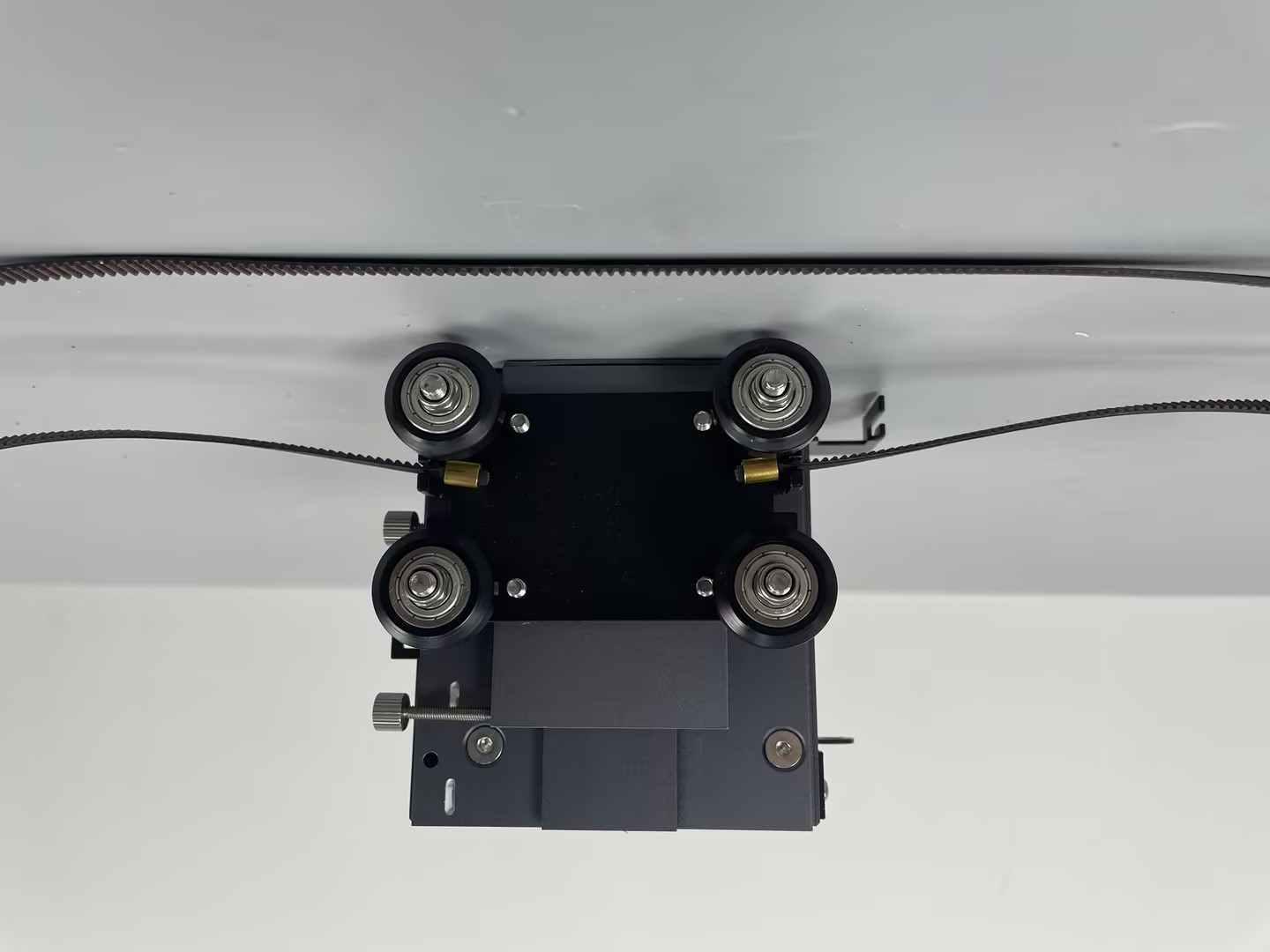

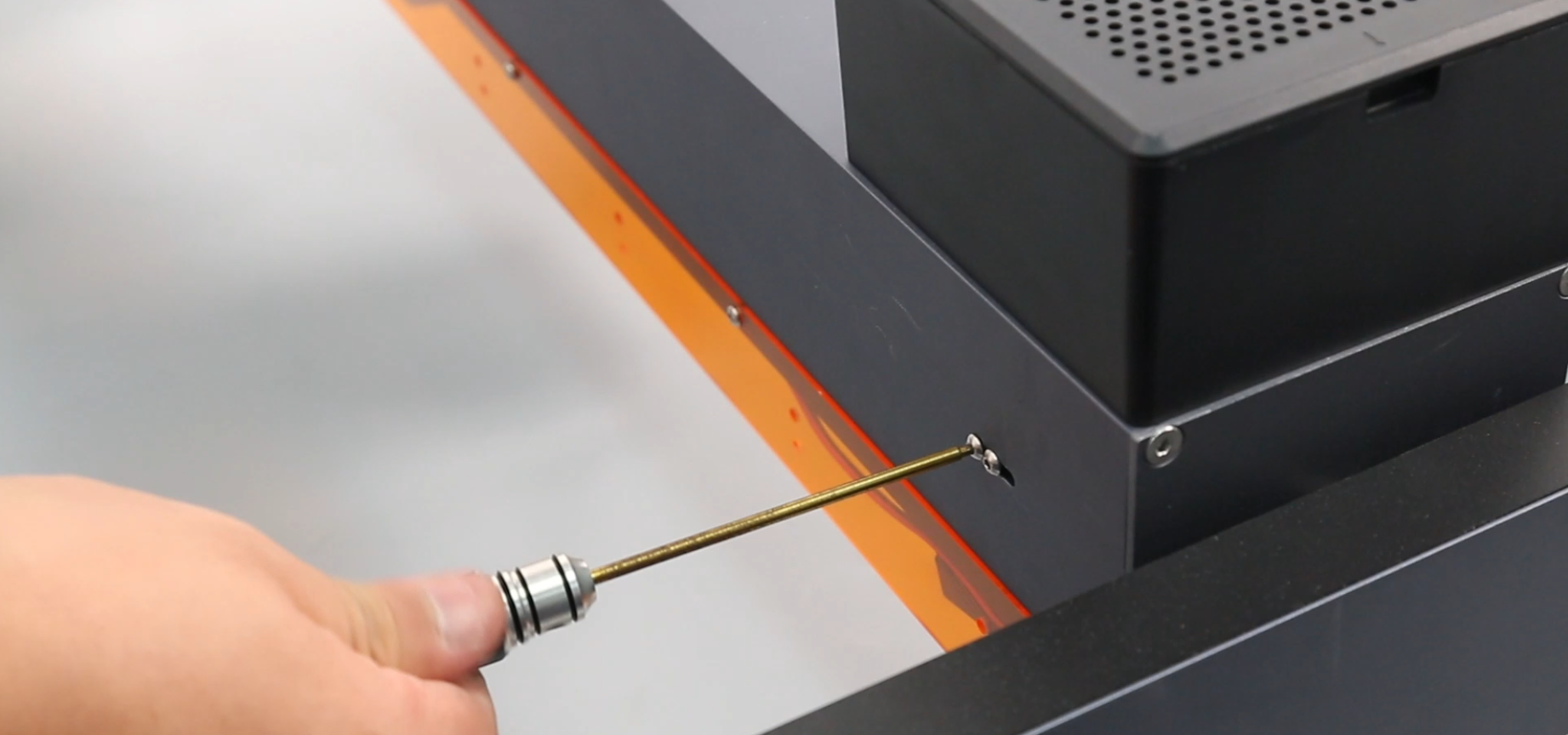

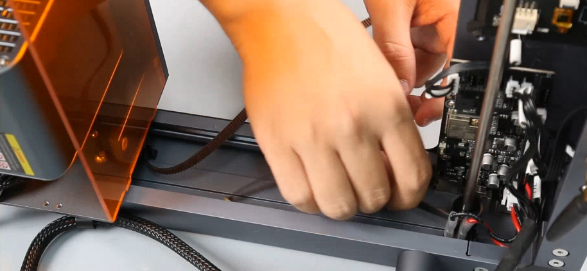

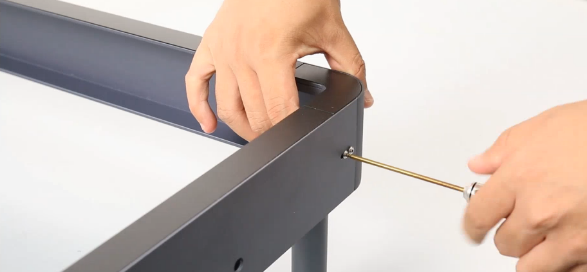

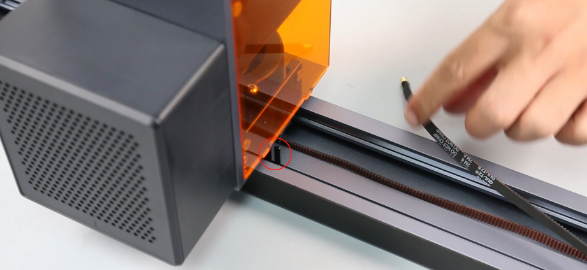

¶ Step 1 - Remove the X-axis timing belt

Remove the magnetic shading plate in front of the X-axis, and use a 2.0mm Allen wrench to loosen the fixing screws of the drive wheel assembly behind the X-axis. Stand the machine up with the X-axis side as the bottom, and use your fingers to push the metal-head buckle at both ends of the timing belt out of the belt fixing grooves on the left and right openings of the laser head connection sheet metal, and then slowly pull out the timing belt.

¶ Step 2 - Replace with new X-axis timing belt

Take out the new timing belt, fold it on the right end, hold the two folded ends with one hand, let the folded part of the timing belt naturally expand into a lasso shape, and then put the timing belt on the X-axis motor drive wheel.

¶ Step 3 - Snap the metal head buckle at the right end of the timing belt into the belt fixing groove on the right side of the laser head connector.

¶ Step 4 - Pass the other end of the timing belt through the bottom of the laser head connector.

¶ Step 5 - Pass the left end of the timing belt through the X-axis drive wheel assembly.

¶ Step 6 - Snap the metal head buckle on the left end of the timing belt into the belt fixing groove on the left side of the laser head connector.

¶ Step 7 - Use your right hand to press against the drive wheel assembly to the left to tighten the timing belt.

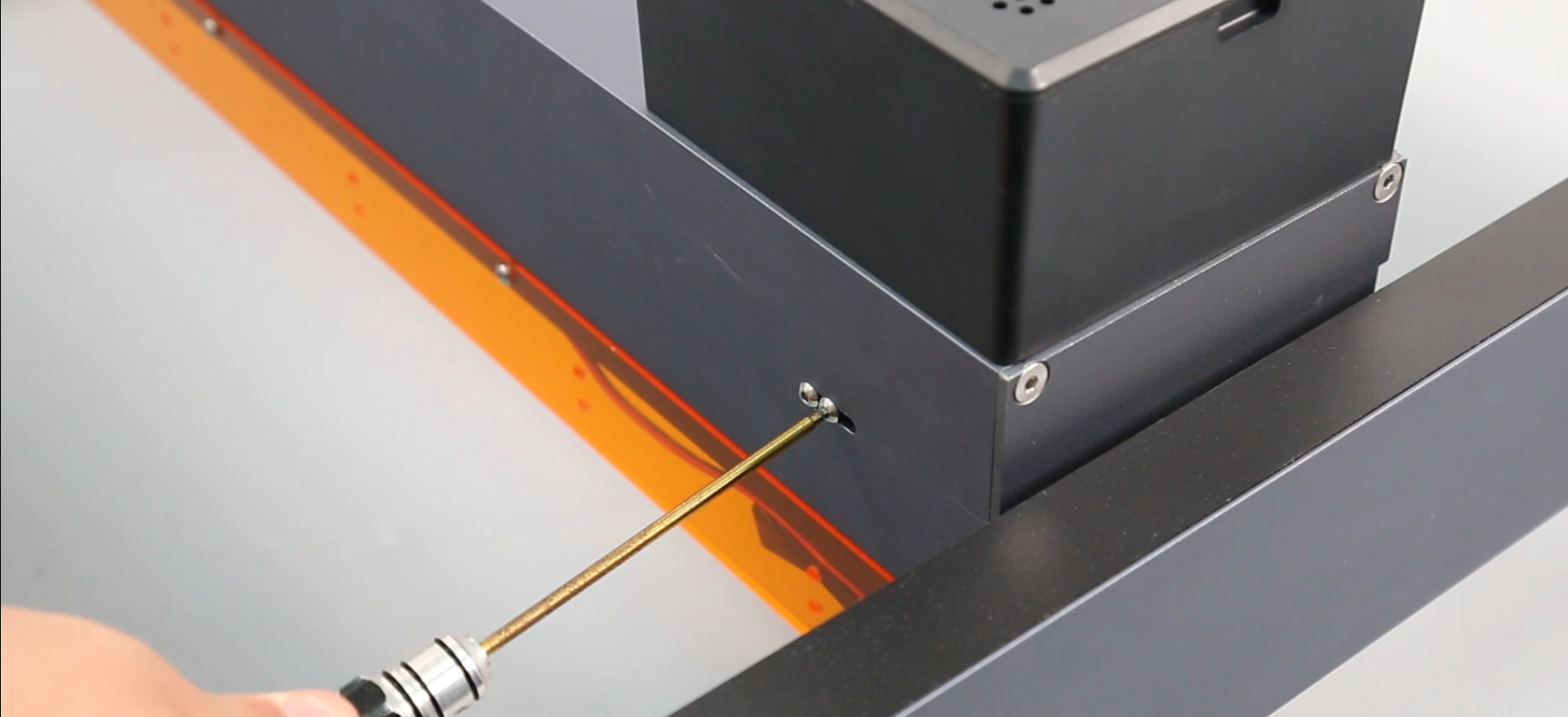

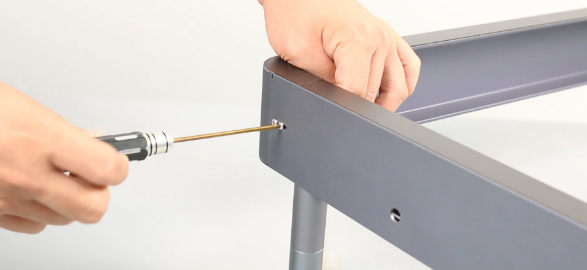

¶ Step 8 - Use a 2.0mm Allen wrench with your left hand to lock and secure the drive wheel assembly.

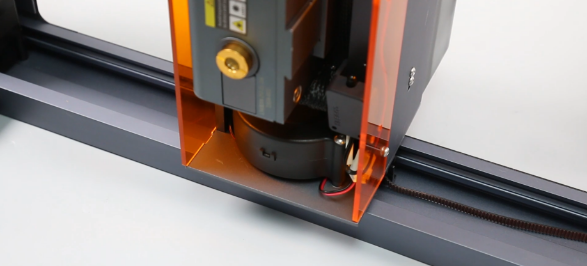

¶ Step 9 - X-axis timing belt replacement completed

Press the synchronous belt with your fingers. If it is neither loose nor tight, the tension is moderate, the movement is smooth, and the cutting and engraving results are ideal, then the replacement of the X-axis timing belt is completed.

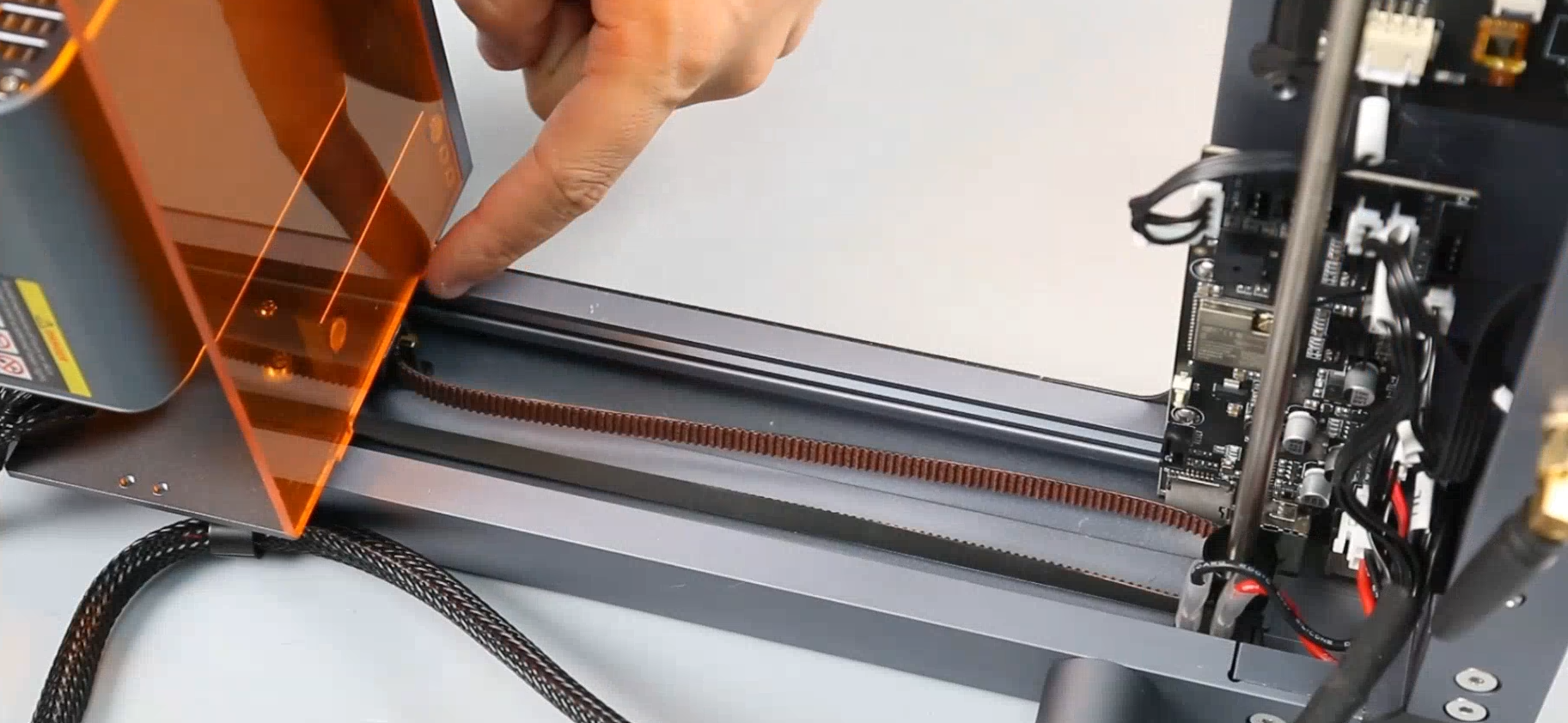

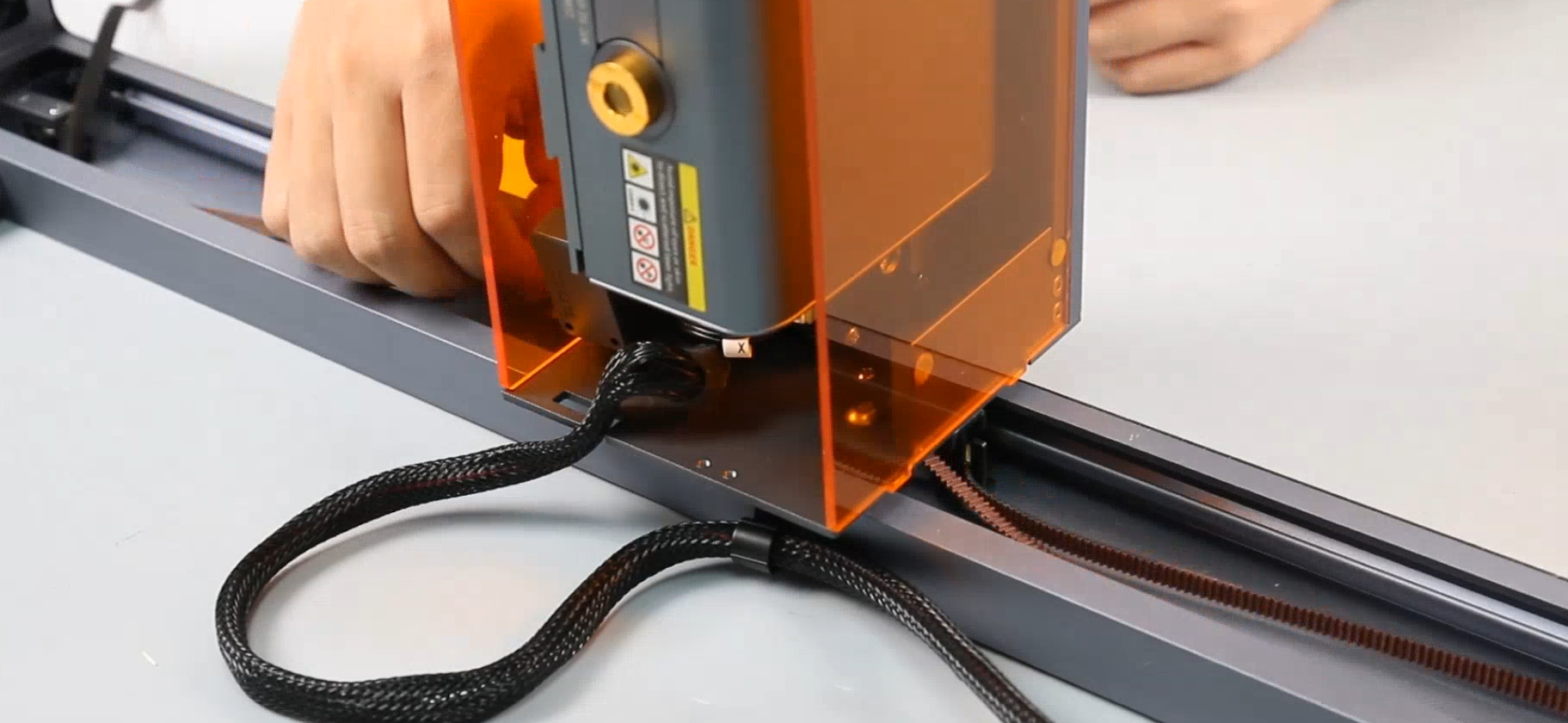

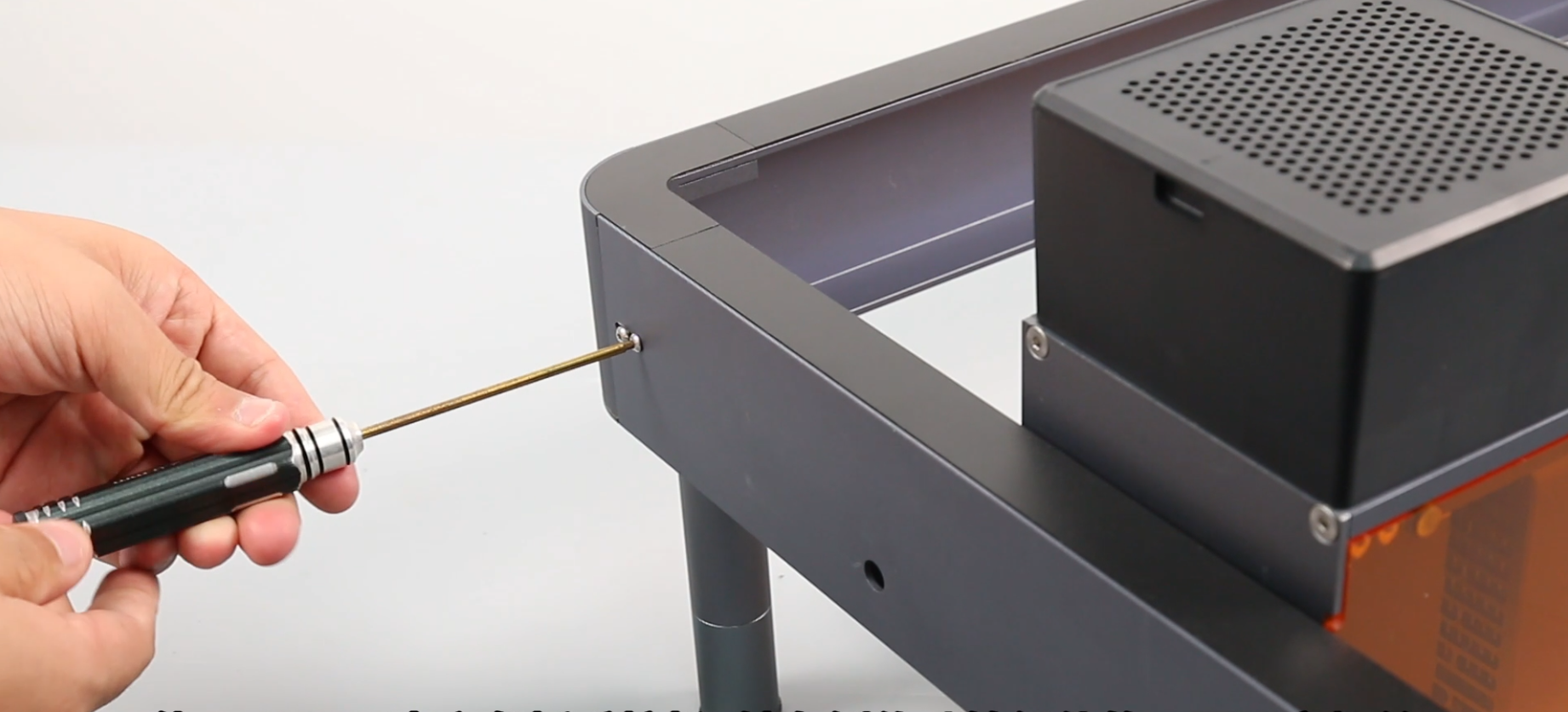

¶ Operation guide: Replacing the timing belt on the right Y-axis

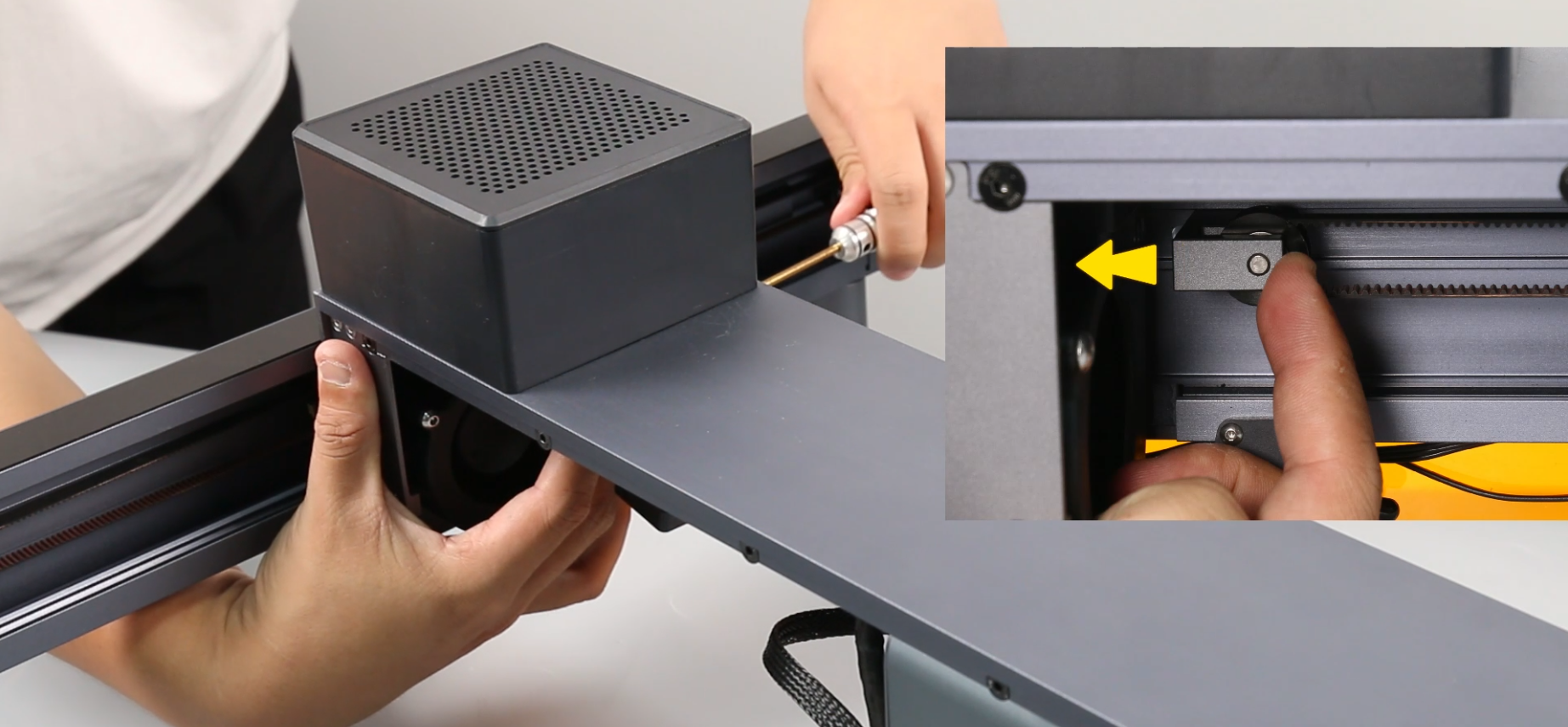

¶ Step 1 - Remove the right Y-axis timing belt

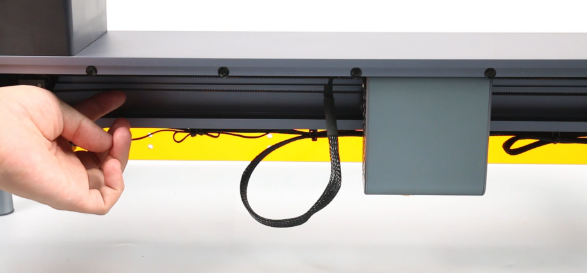

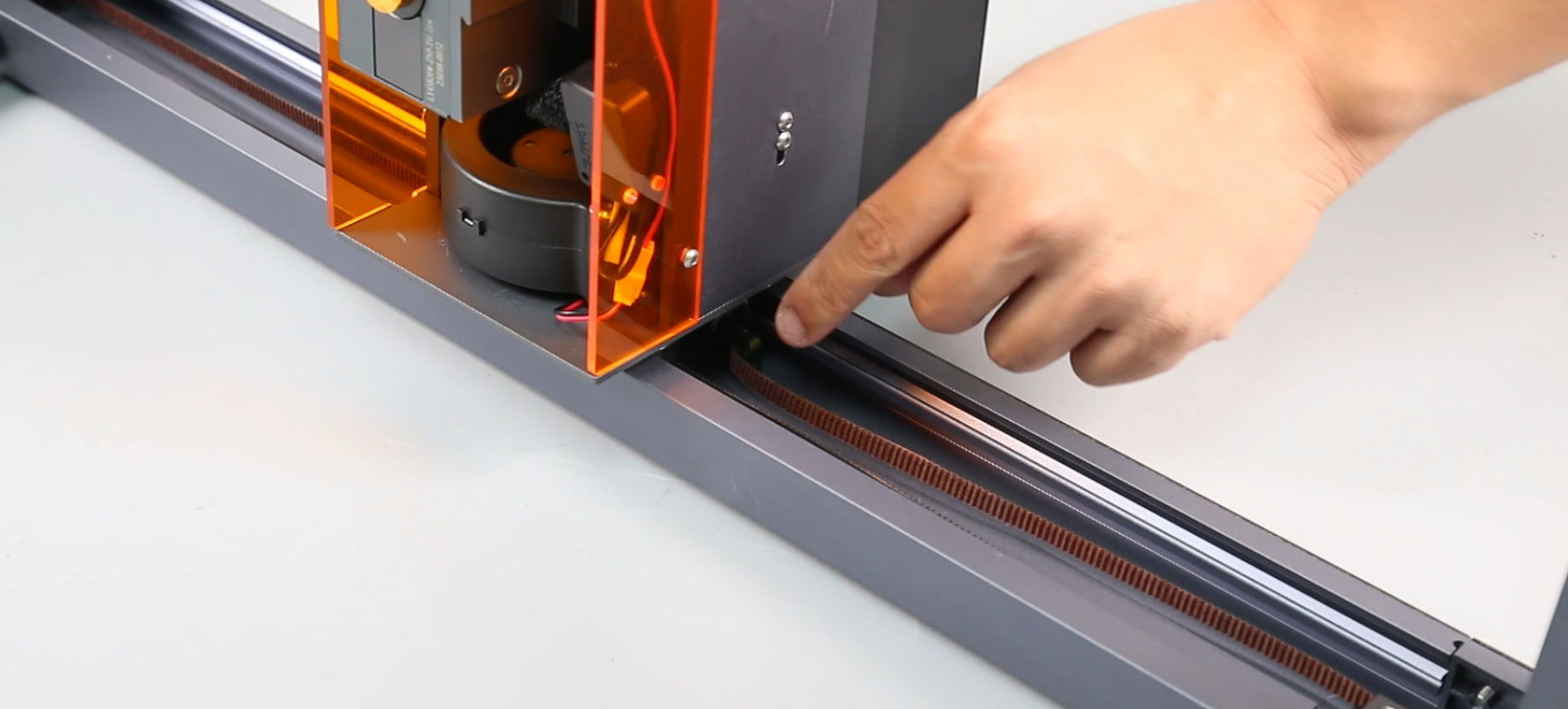

Use a 2.0mm Allen wrench to loosen the fixing screws of the drive wheel assembly behind the Y-axis; stand the machine up with the Y-axis as the bottom, and use your fingers to remove the metal-head buckle at both ends of the timing belt from the belt fixing grooves on the left and right openings of the Y-axis sheet metal connector, and then slowly pull out the timing belt.

¶ Step 2 - Snap the metal head buckle on the right end of the new timing belt into the belt fixing groove on the right side of the sheet metal connector.

¶ Step 3 - Pass the metal head buckle on the timing belt's left end from the top of the Y-axis timing pulley in and out from the bottom.

¶ Step 4 - Pass the metal head buckle on the timing belt's left end between the upper and lower V-wheels at the bottom of the sheet metal connector.

¶ Step 5 - Pass the timing belt metal head buckle through the Y-axis drive wheel assembly.

¶ Step 6 - Finally, snap the metal head buckle of the timing belt into the belt fixing groove of the sheet metal connector.

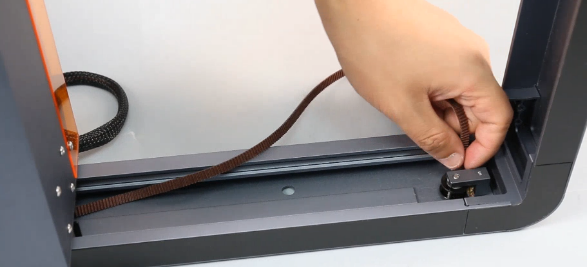

¶ Step 7 - Use your right hand to press the drive wheel assembly to tighten the timing belt.

¶ Step 8 - Use a 2.0mm Allen wrench to tighten the drive wheel assembly fixing screws.

¶ Step 9 - Press the timing belt with your fingers, the tension is moderate, and the right Y-axis timing belt replacement is complete.

Press the synchronous belt with your fingers. If it is neither loose nor tight, the tension is moderate, the movement is smooth, and the cutting and engraving results are ideal, then the replacement of the Y-axis timing belt is completed.

¶ Operation guide: Replacing the timing belt on the left Y-axis

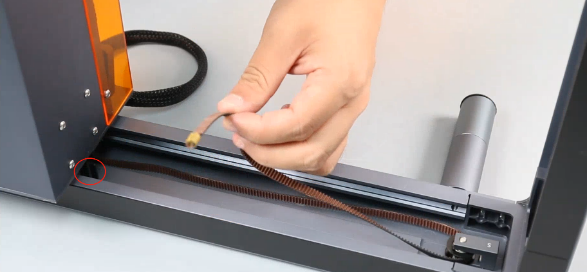

¶ Step 1 - Remove the left Y-axis timing belt

Use a 2.0mm Allen wrench to loosen the fixing screw of the drive wheel assembly behind the Y-axis. Stand the machine up with the Y-axis as the bottom, and use your fingers to remove the metal-head buckle at both ends of the timing belt from the belt fixing grooves on the left and right openings of the Y-axis sheet metal connector, and then slowly pull out the timing belt.

¶ Step 2 - Snap the metal head buckle on the right end of the new timing belt into the belt fixing groove on the right side of the sheet metal connector.

¶ Step 3 - Pass the left end of the timing belt through the Y-axis drive wheel assembly.

¶ Step 4 - Pass the other end of the timing belt between the upper and lower V-wheels at the bottom of the sheet metal connector.

¶ Step 5 - Pass the other end of the timing belt through the left side of the Y-axis motor drive wheel.

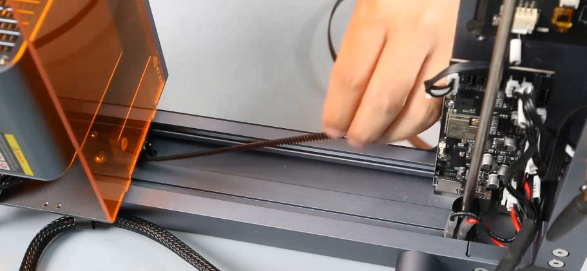

¶ Step 6 - Use the short end of the Allen wrench to hook out the timing belt from the right side of the Y-axis motor drive wheel.

¶ Step 7 - Snap the metal head buckle on the left end of the timing belt into the belt fixing groove on the left side of the sheet metal connector.

¶ Step 8 - Press the drive wheel assembly with your right hand to tighten the timing belt.

¶ Step 9 - Use a 2.0mm Allen wrench to tighten the drive wheel assembly fixing screws.

¶ Step 10 - Press the timing belt with your fingers, the tension is moderate, and the left Y-axis timing belt replacement is complete.

Press the synchronous belt with your fingers. If it is neither loose nor tight, the tension is moderate, the movement is smooth, and the cutting and engraving results are ideal, then the replacement of the Y-axis timing belt is completed.

¶ Check the tightness of the timing belt after the replacement

Press the timing belt with your fingers. It should be neither loose nor tight, the tension should be moderate, and the movement should be smooth.