During auxiliary leveling, the nozzle may be too far from the heated bed even the nut has been completely unscrewed. To fix this, you need to reduce the Z-offset value (the distance from the top of the heated bed washers to the tip of the nozzle) to lower the nozzle closer to the bed.

¶ Instructions

¶ Reference Video

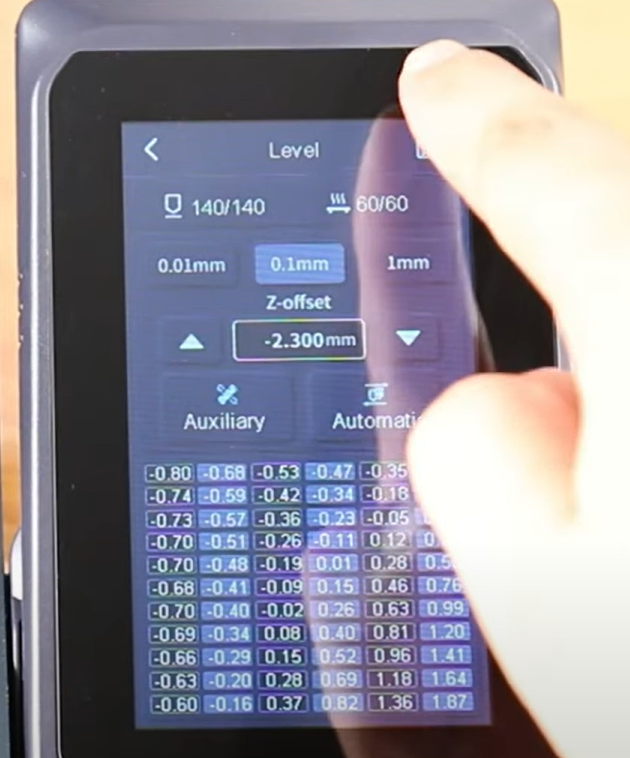

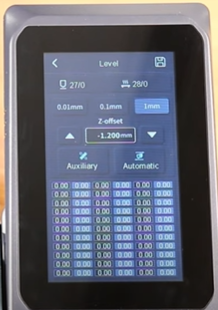

¶ Reduce the Z-offset value

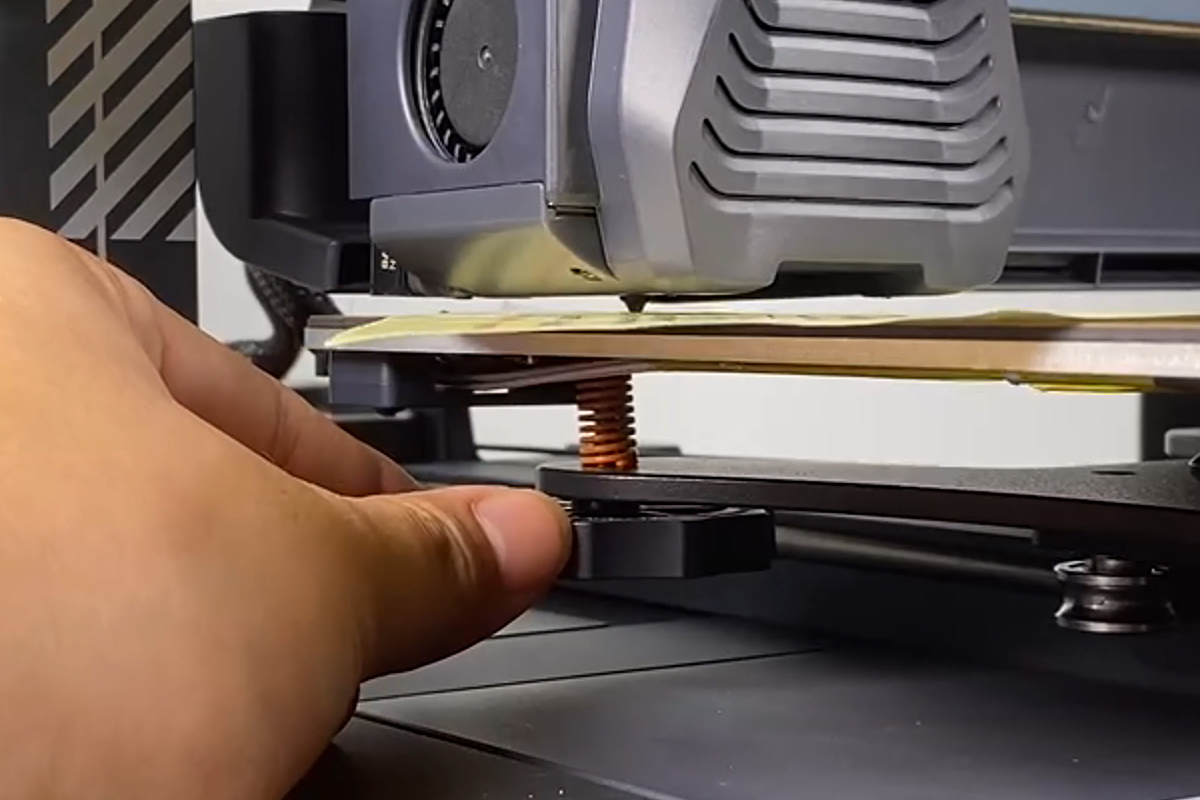

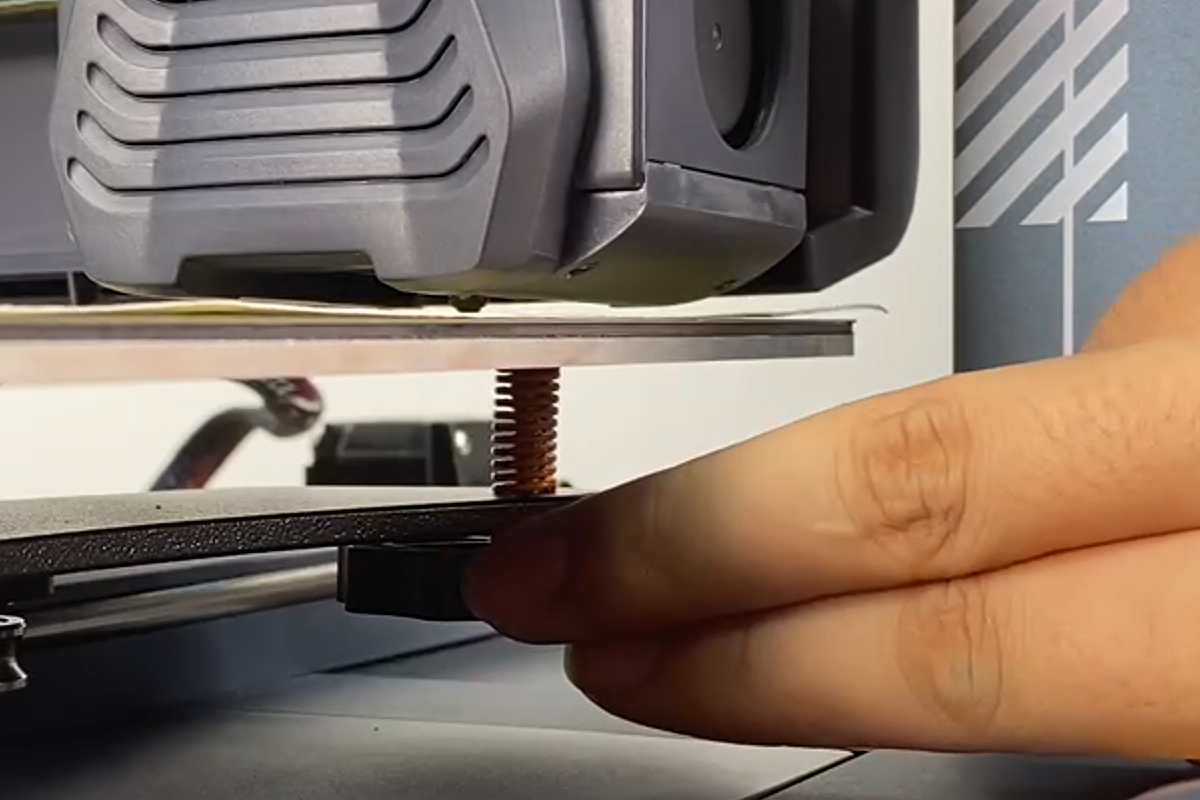

- Return the nut to its initial secure.

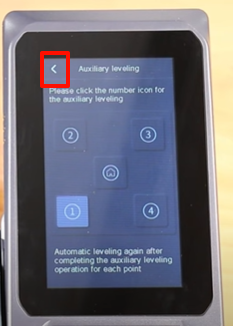

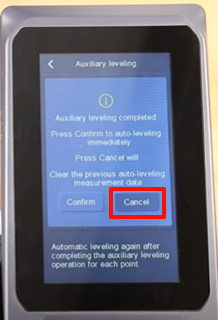

- Click Back - Cancel and go to the auxiliary leveling interface.

- Adjust the Z-offset value to about -1mm.

NOTE: The Z-offset value usually be negative. The closer the Z-offset is to zero, the further away from the heated bed surface the tip of the nozzle will be moved.

¶ Re-operate the Auxiliary Leveling

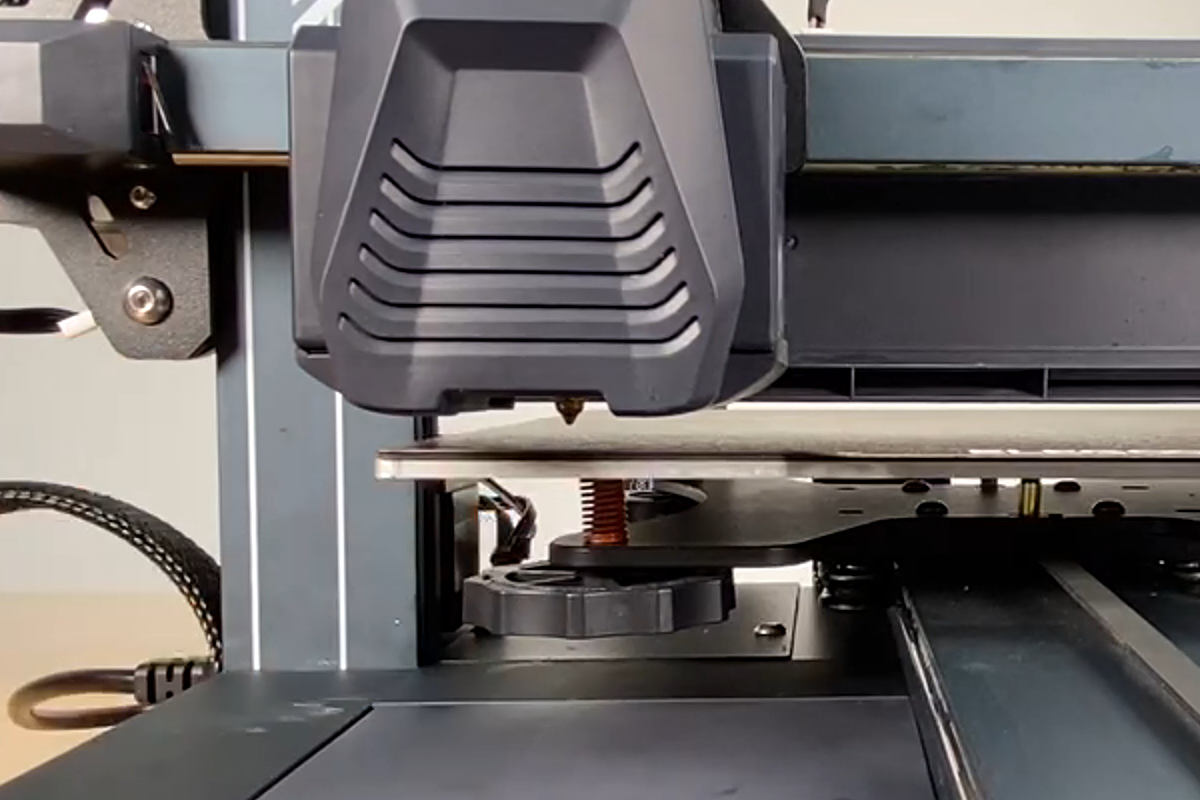

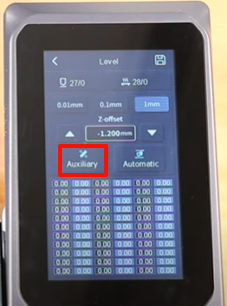

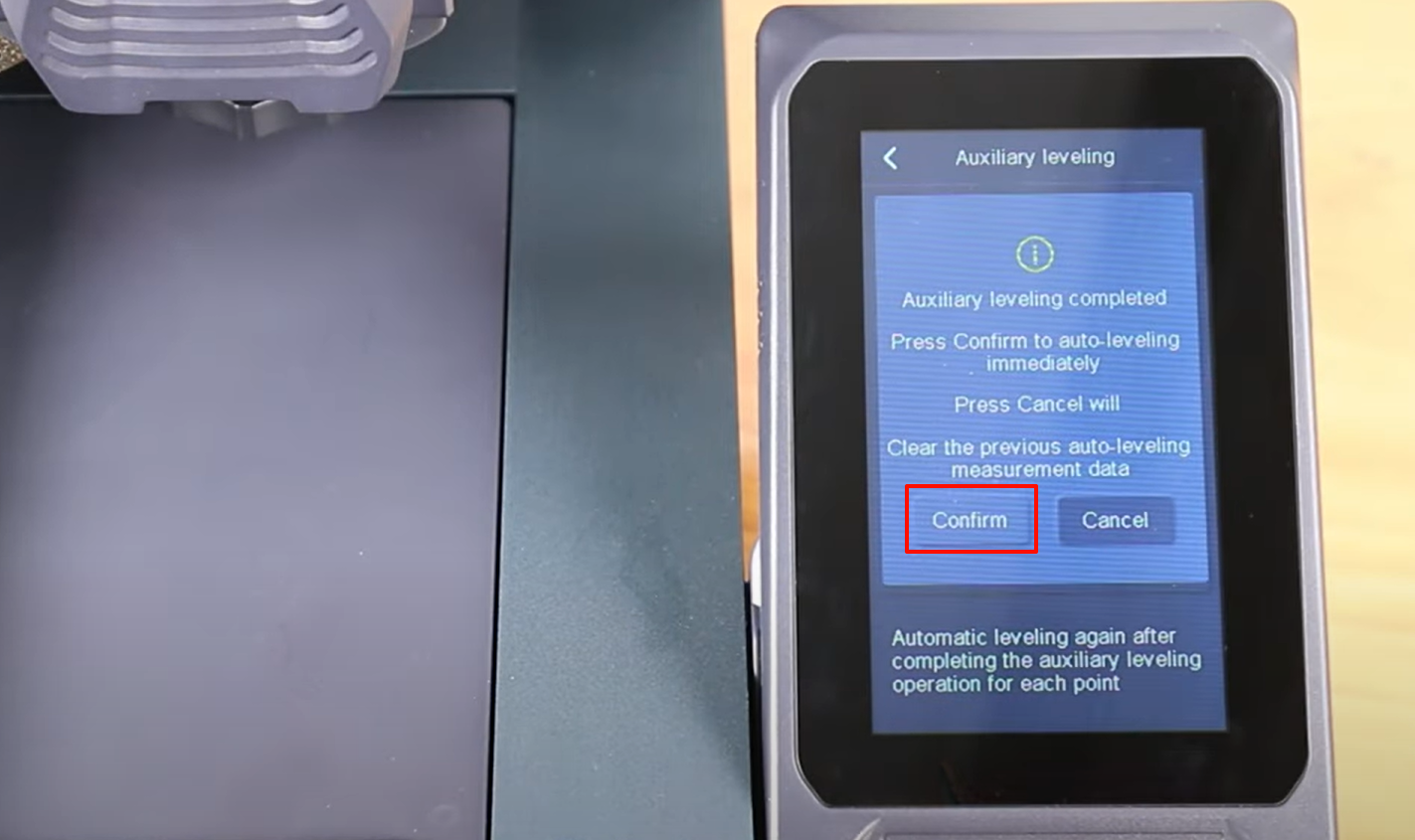

- Click Auxiliary - Confirm. The printer starts the homing process.

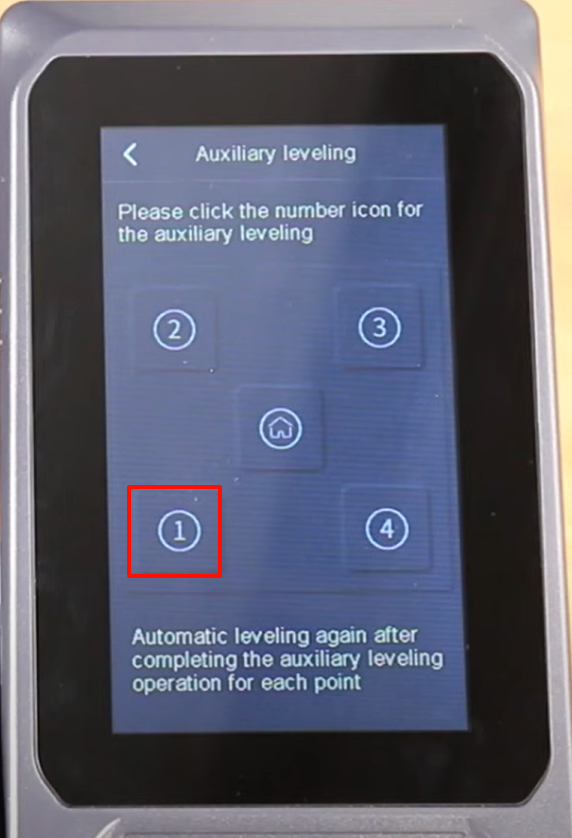

- Click ① and re-level the first leveling point.

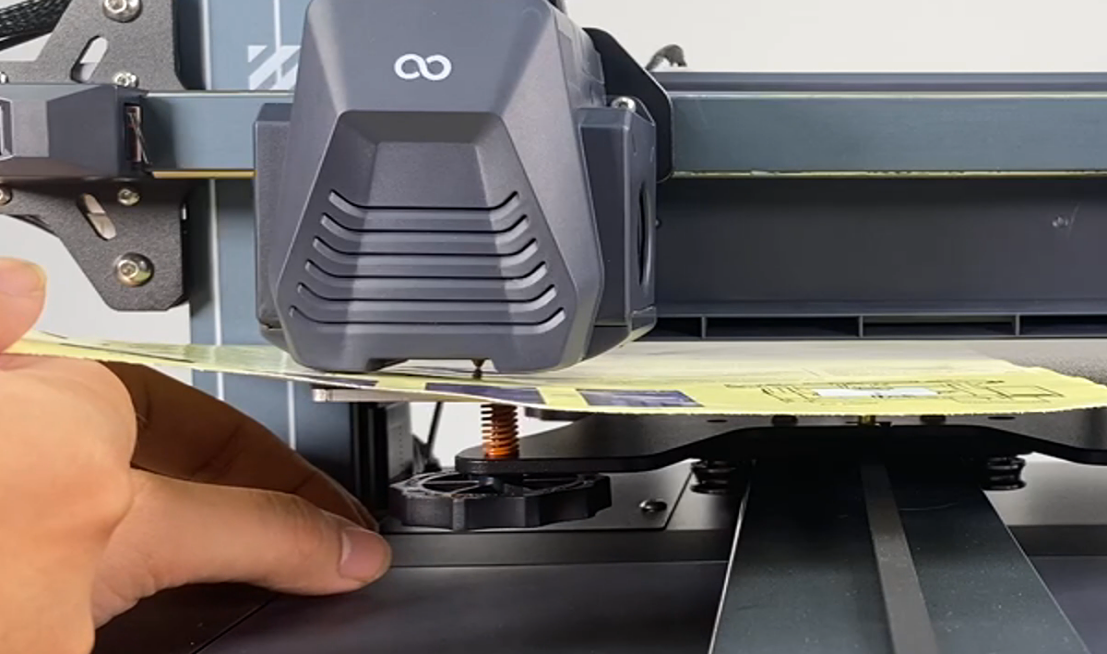

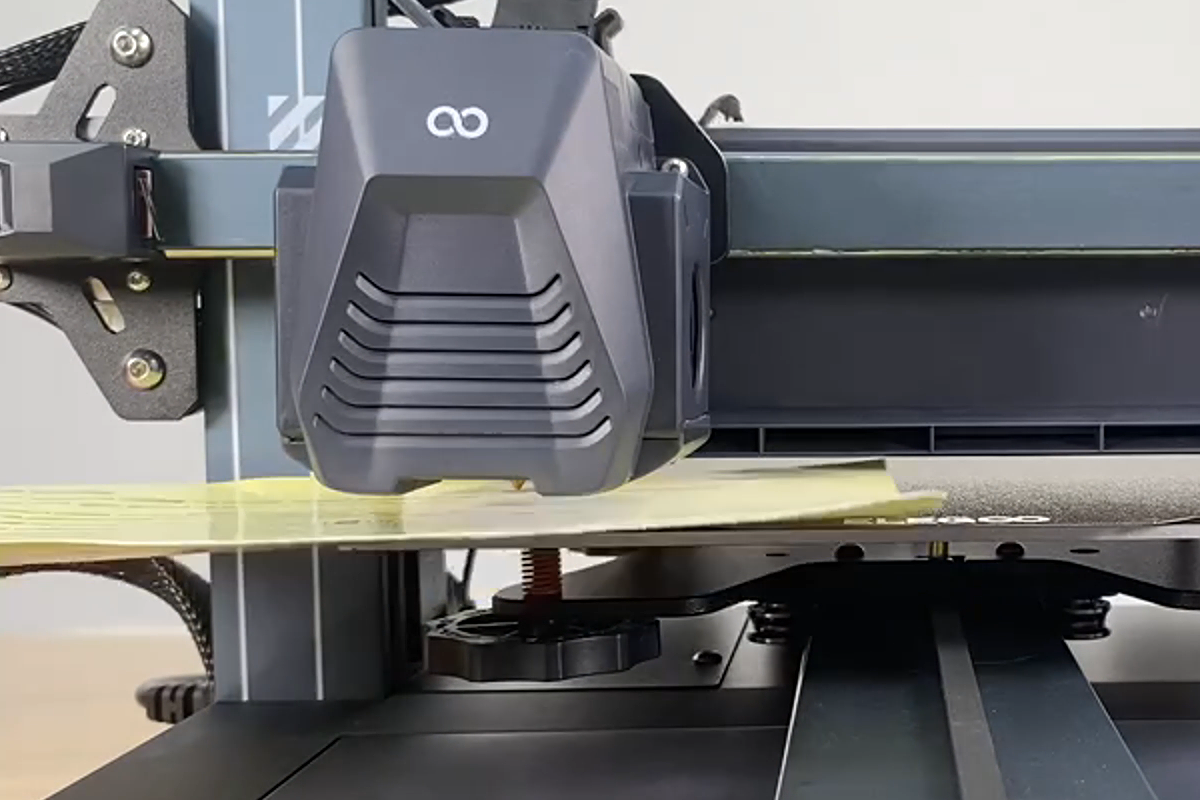

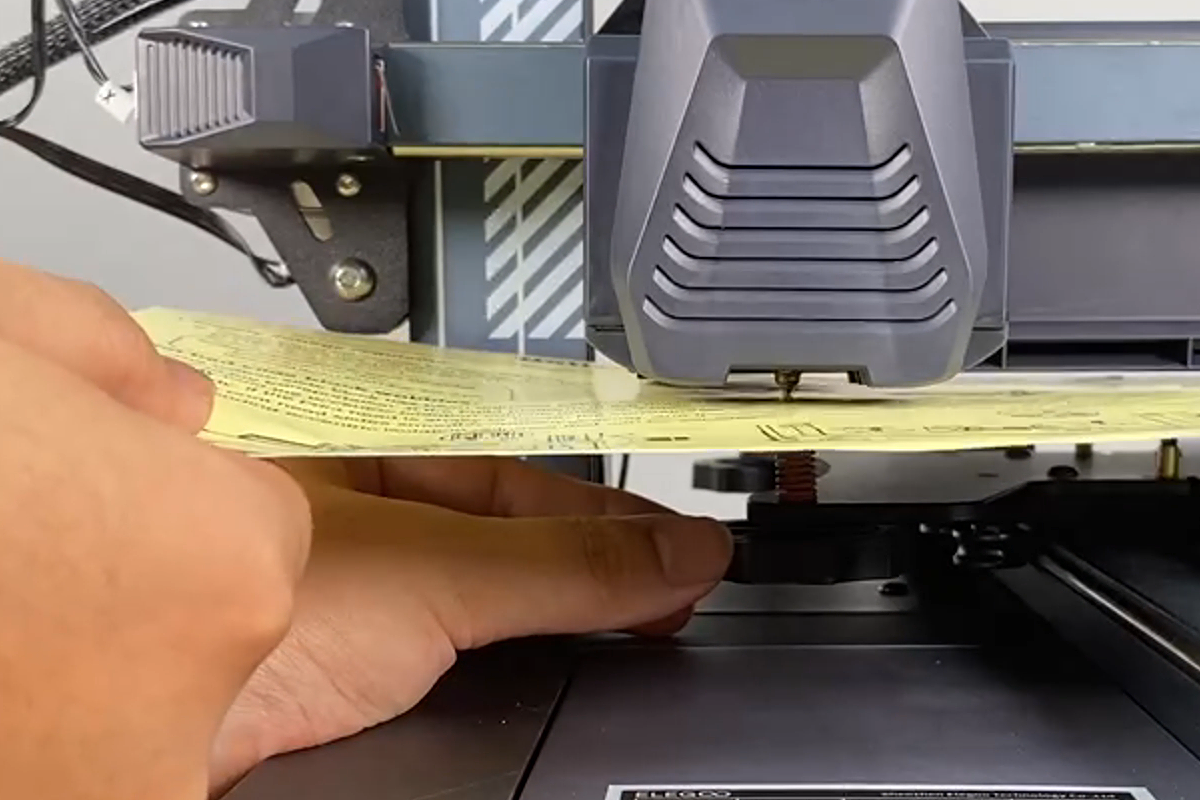

- Put the A4 paper between the nozzle and the heated bed.

- Adjust the nut while pushing and pulling the leveling paper. When pushing and pulling the paper, feel the appropriate resistance, and it will not be too loose or too tight.

NOTE: If the distance between the nozzle and the hot bed is still large, you can adjust the Z-offset value again.

- Continue to level the other three leveling points in the same way.

¶ Automaticaly level the printer

- After the auxiliary leveling, click Back - Confirm and the printer starts homing process automatically.

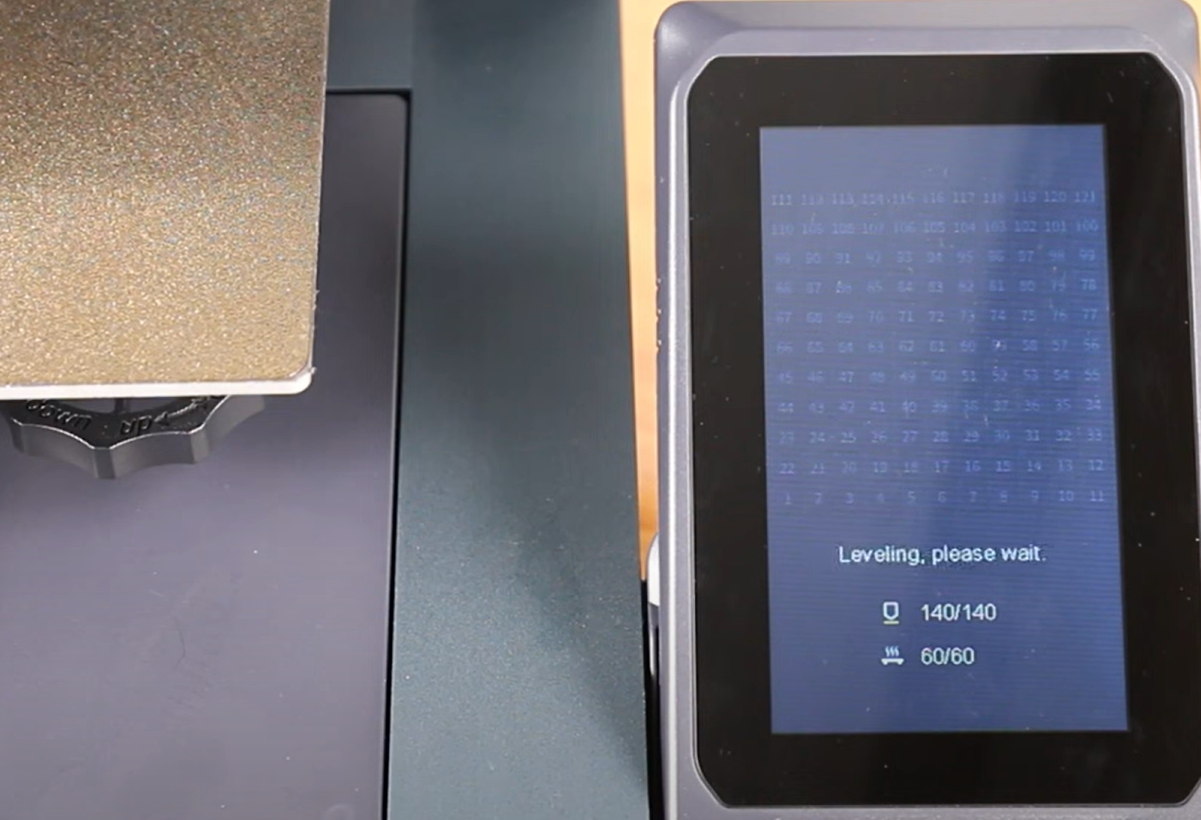

- After the homing process, the printer will automatically heat the nozzle and heated bed. The printer automatically levels and detects the 121 points on the surface of the heated bed.

¶ Save the Correct Z-offset value

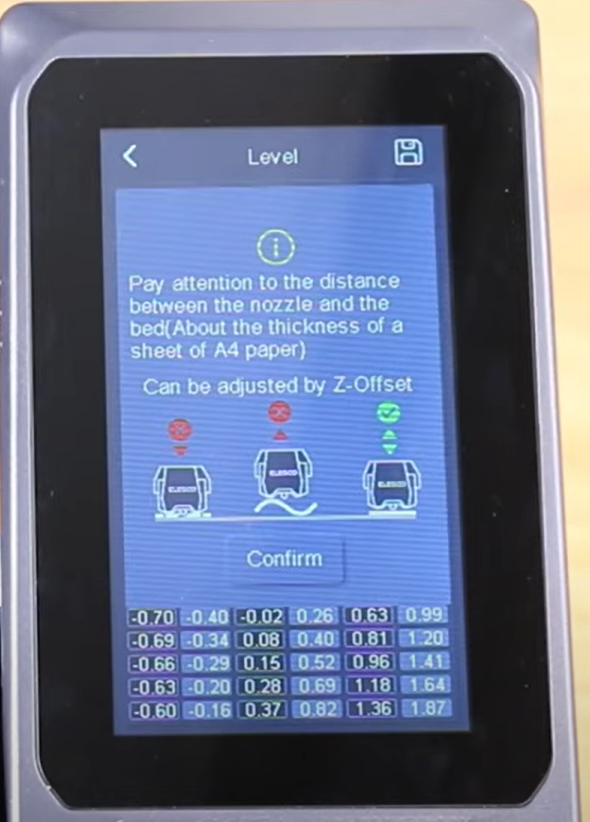

- Prepare an A4 paper and place it between the nozzle and the heated bed.

- Constantly push and pull the A4 paper and adjust the Z-offset value. There is obvious friction when pushing and pulling the paper, and the paper can only be pulled out without being pushed forward, and the adjustment is completed.

- Click Save - Confirm and save the correct Z-offset value.