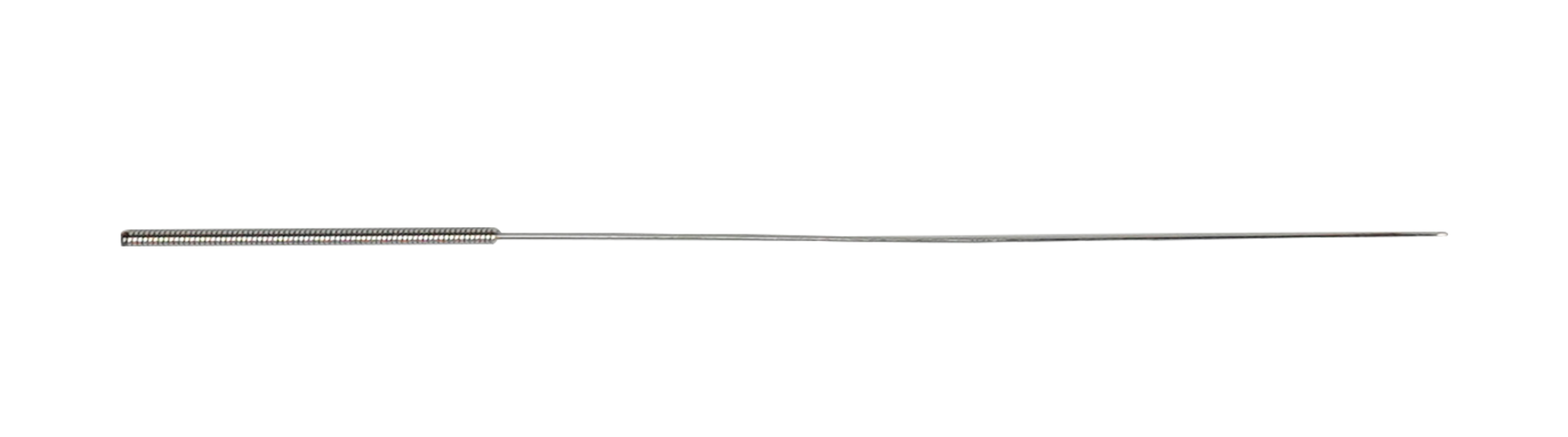

¶ Tools and Materials

Unclogging needle

¶ Tutorial Video

¶ Instruction

-

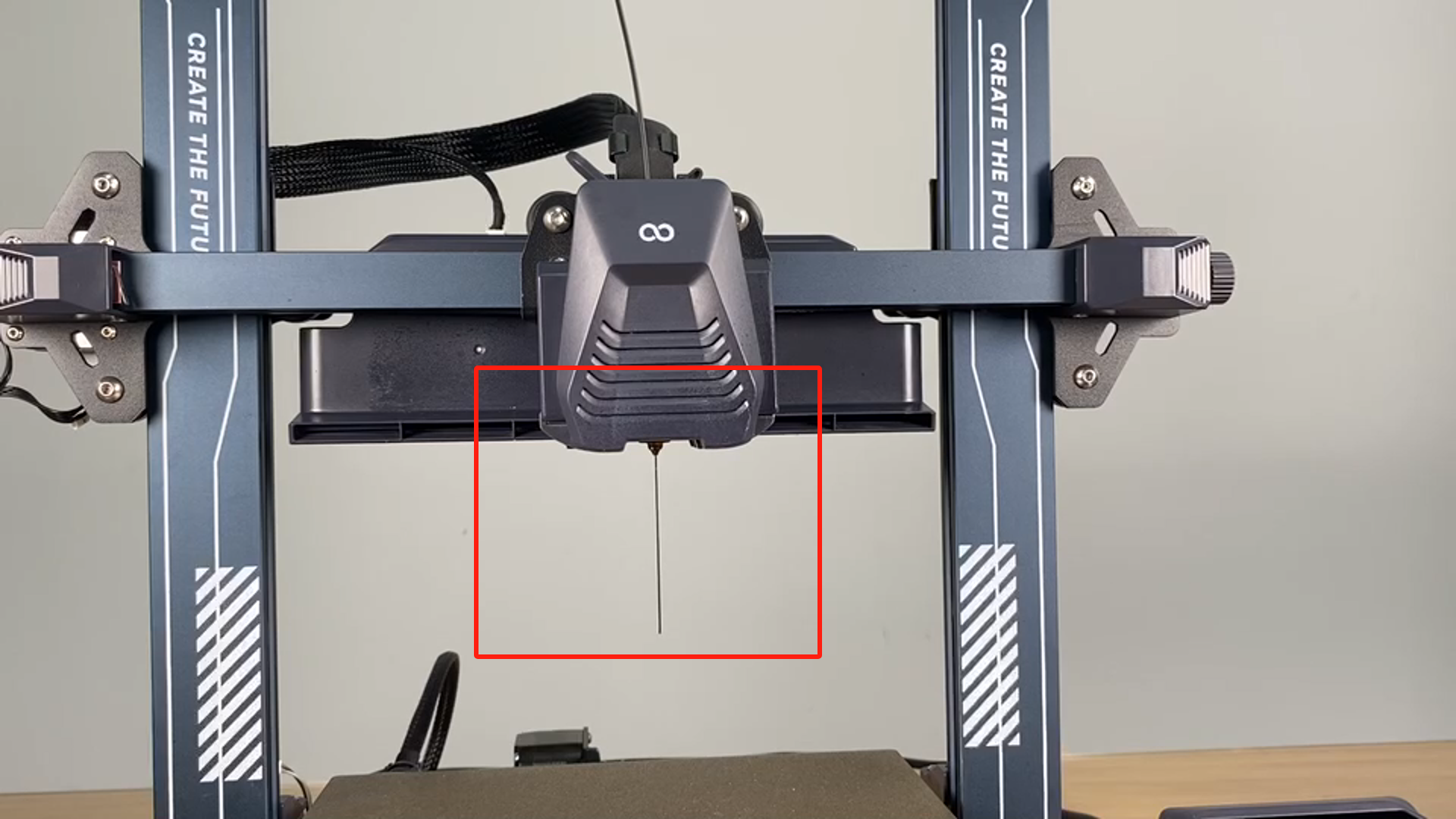

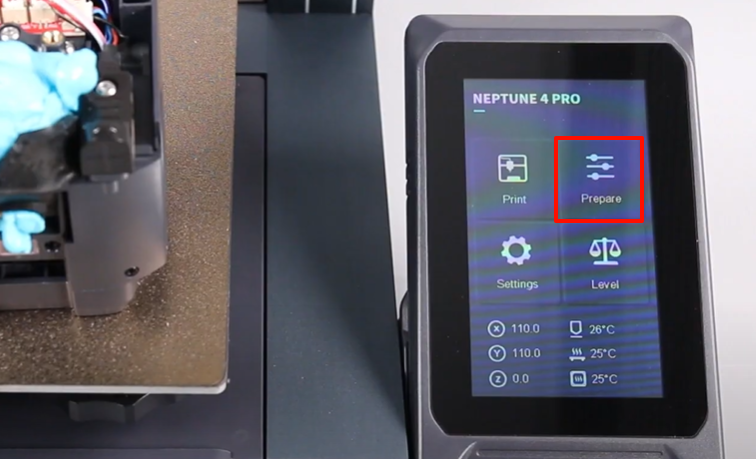

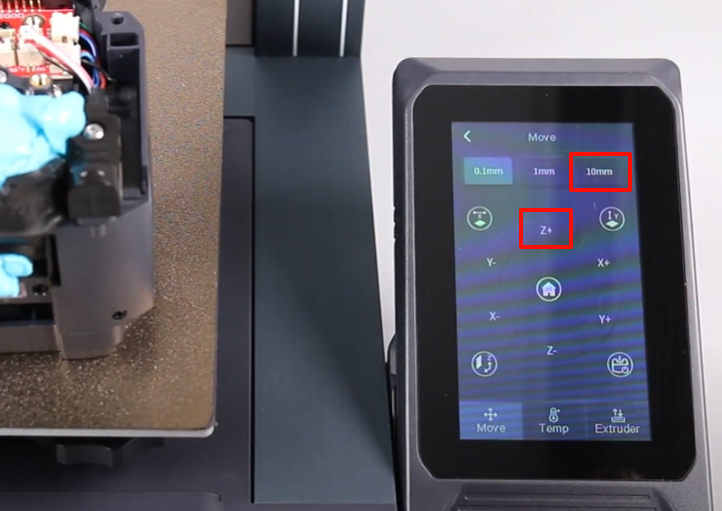

On the touchscreen, click "Prepare" and enter the "Move" interface, select 10mm travel, and then click the "Z+" icon to raise the Z axis to a height of about 200mm for subsequent operation.

-

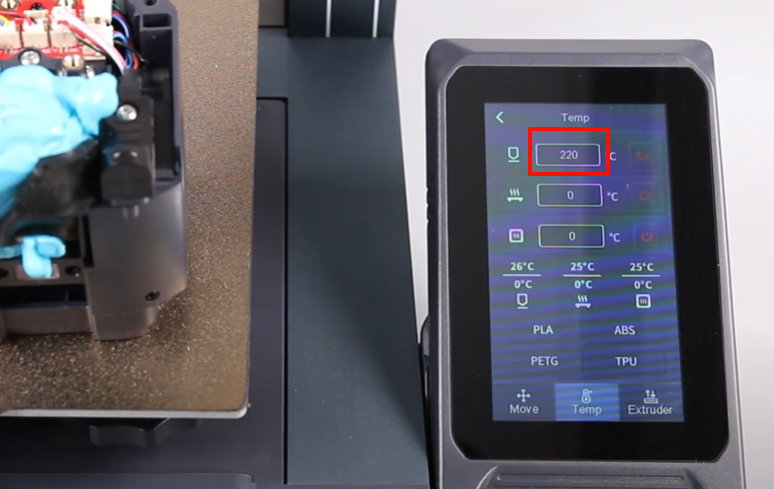

Touch "Function" on the temperature control interface to enter the Prepare interface. Set the temperature of the nozzle to 220 ℃.

-

After observing the nozzle heating to the set temperature, click the "Feed and Discharge" icon, and after entering the interface, click the "Feed" icon.

-

Watch the extruder turn, but no consumables are squeezed out of the nozzle.

-

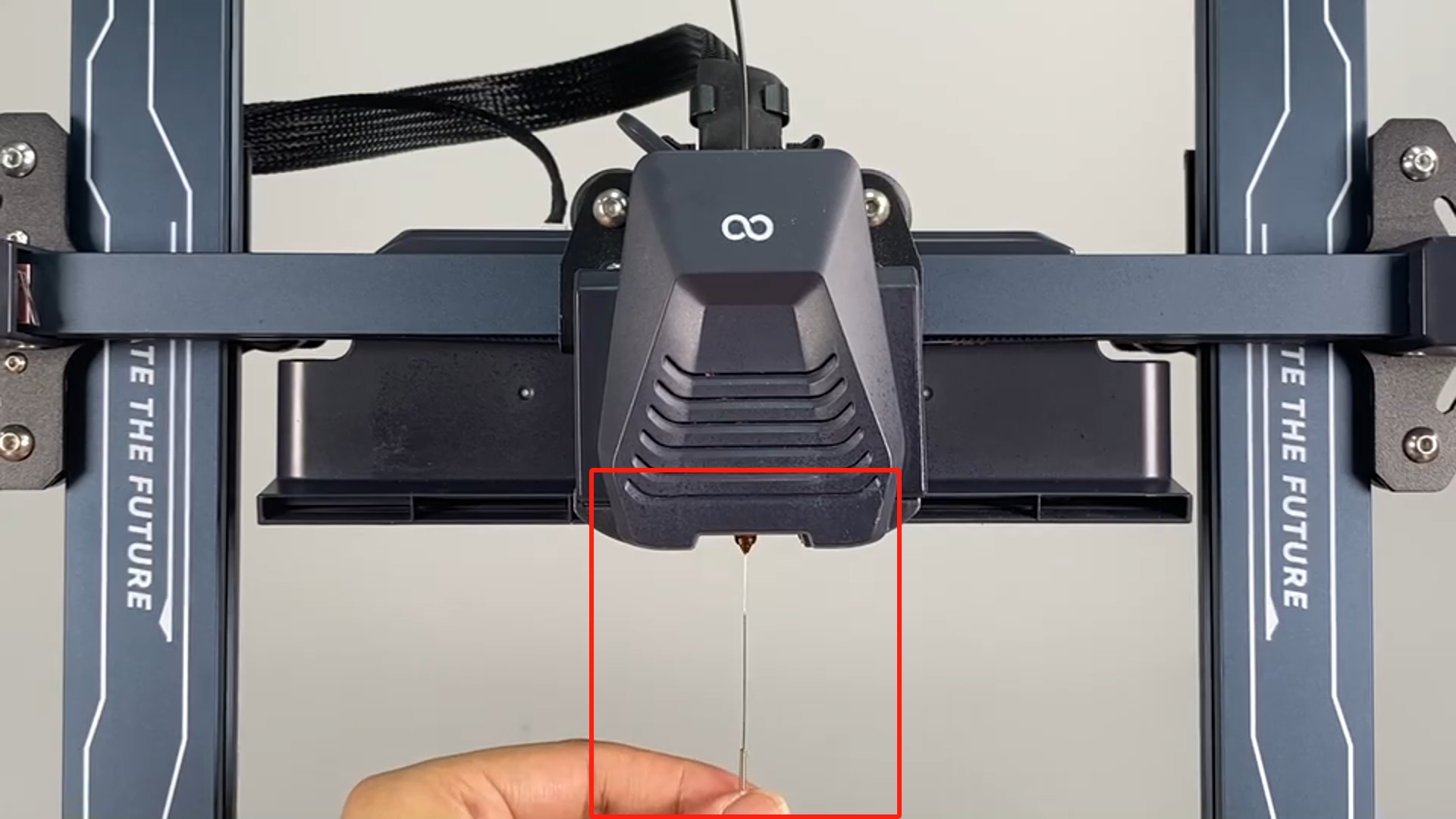

If the nozzle cannot extrude the consumables normally, insert a 0.35mm unclogging needle into the nozzle to clean the remaining consumables in the nozzle.

Note: The nozzle is hot, handle it carefully.

-

After unclogging the nozzles, click the "Feed" icon on the touch screen again.

-

Observe that the extruder gear rotates normally to extrude the consumables, and there is no lag, you can continue to use the printer.