¶ Tools and Materials

- 2.0mm Allen key x 1

- 2.5mm Allen key x 1

- 3.0mm Allen key x 1

- 4.0mm Allen key x 1

- A pair of diagonal pliers

- Cable ties

- A new spring

¶ Tutorial Video

¶ Instruction

Make sure to power off the printer and unplug the power cord before operation.

¶ Remove the old spring

- Use a 2.0 mm Allen key to loosen the 7 screws securing the back cover of the printer and remove the back cover.

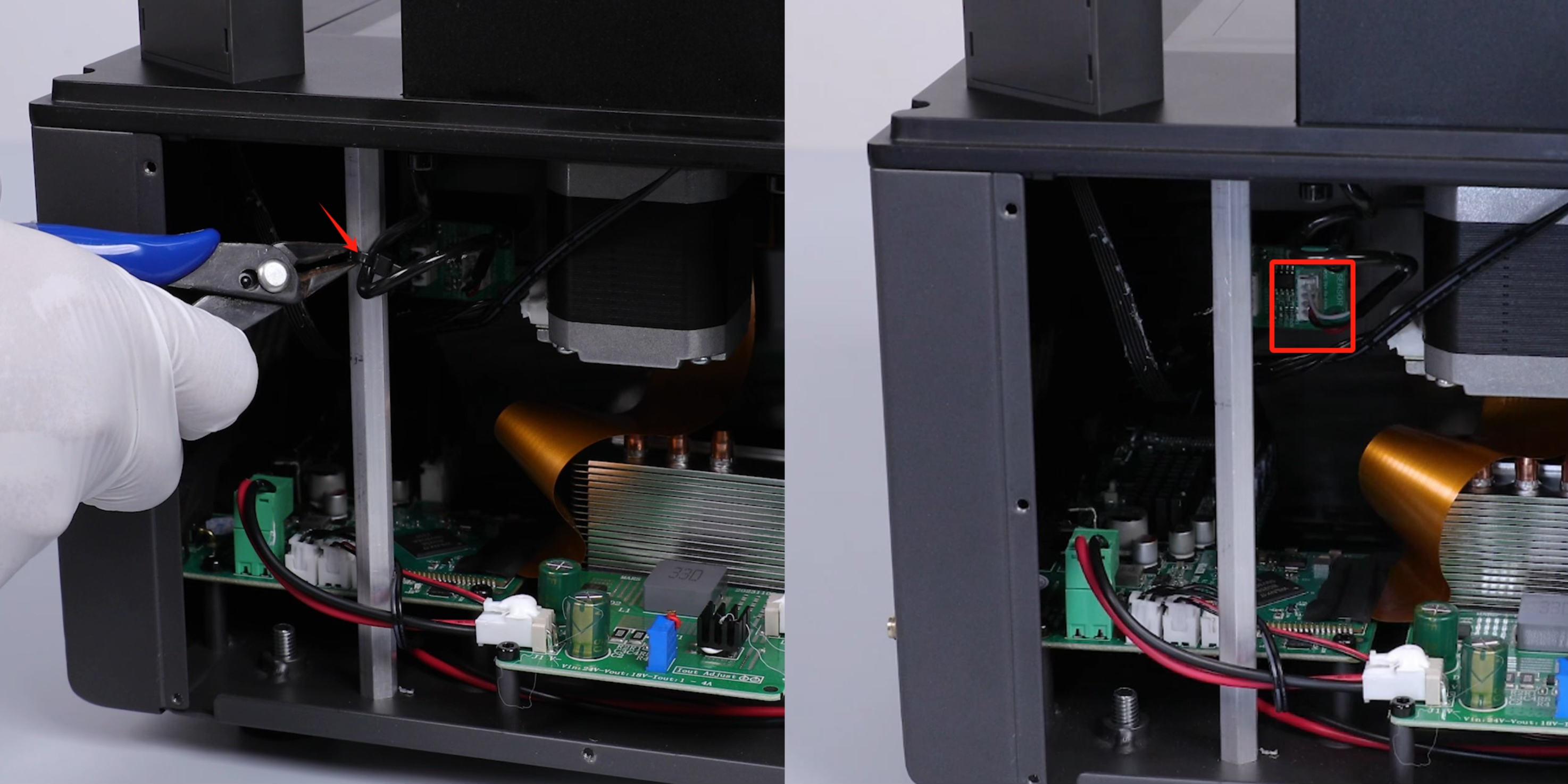

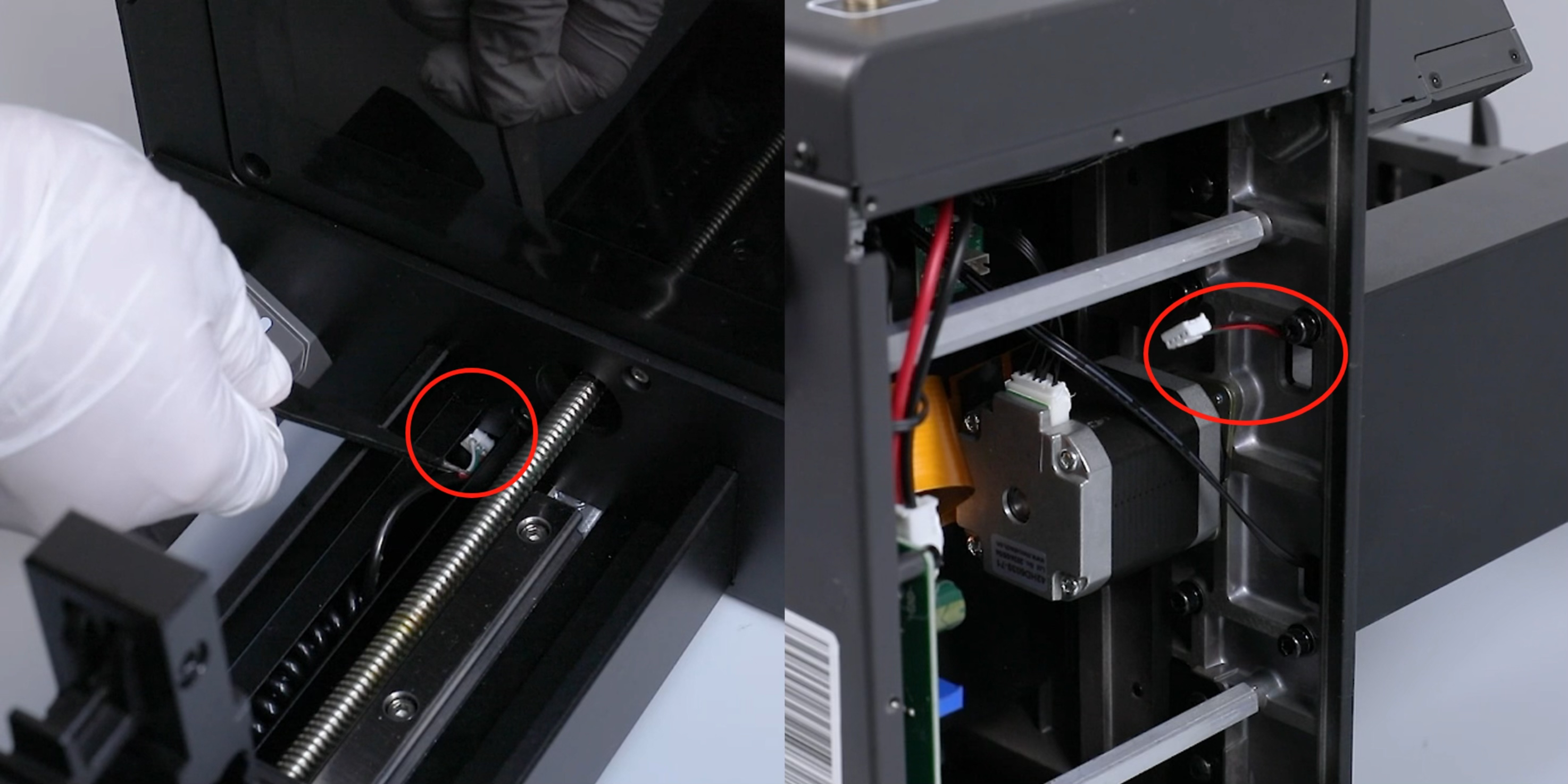

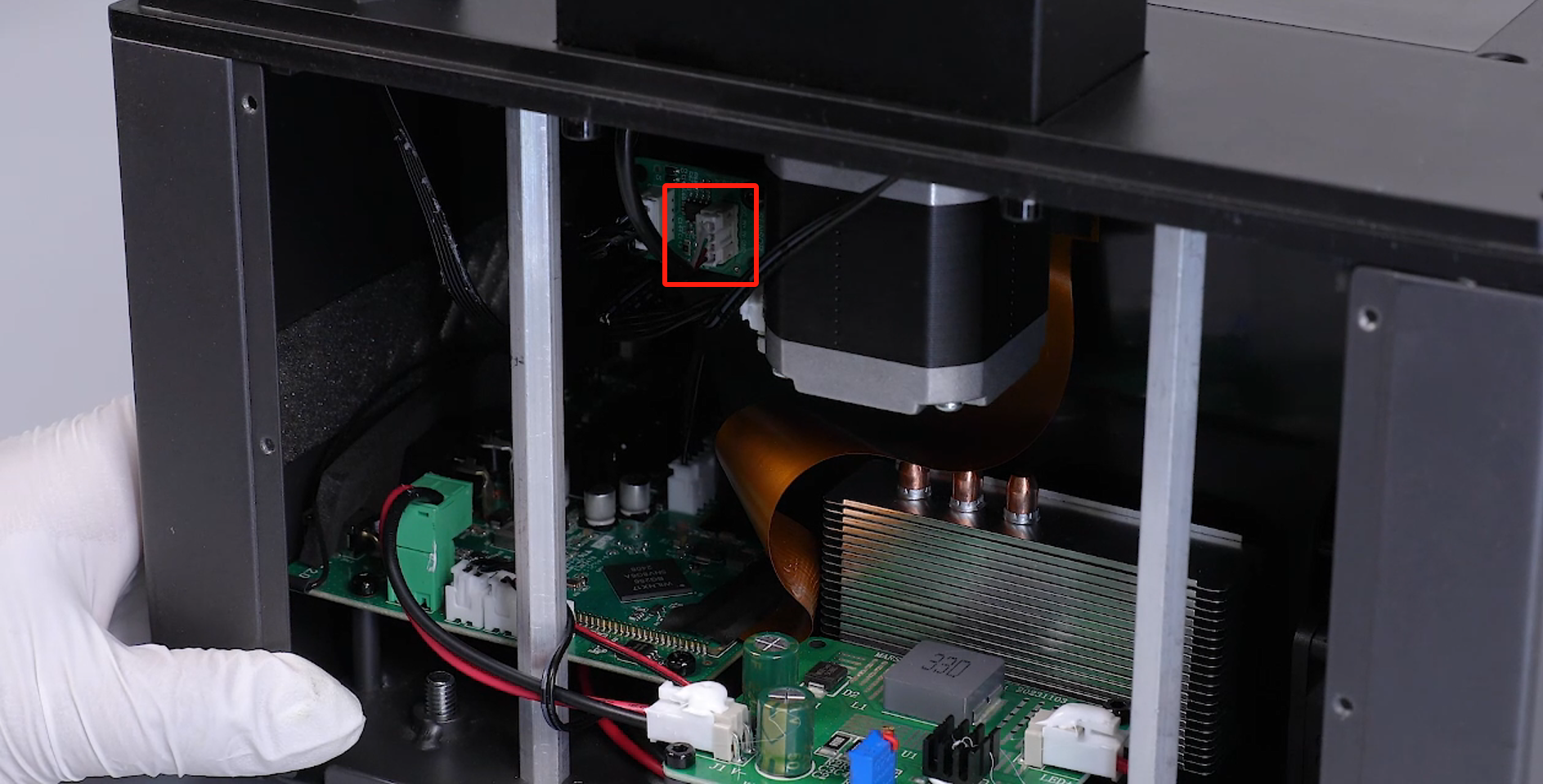

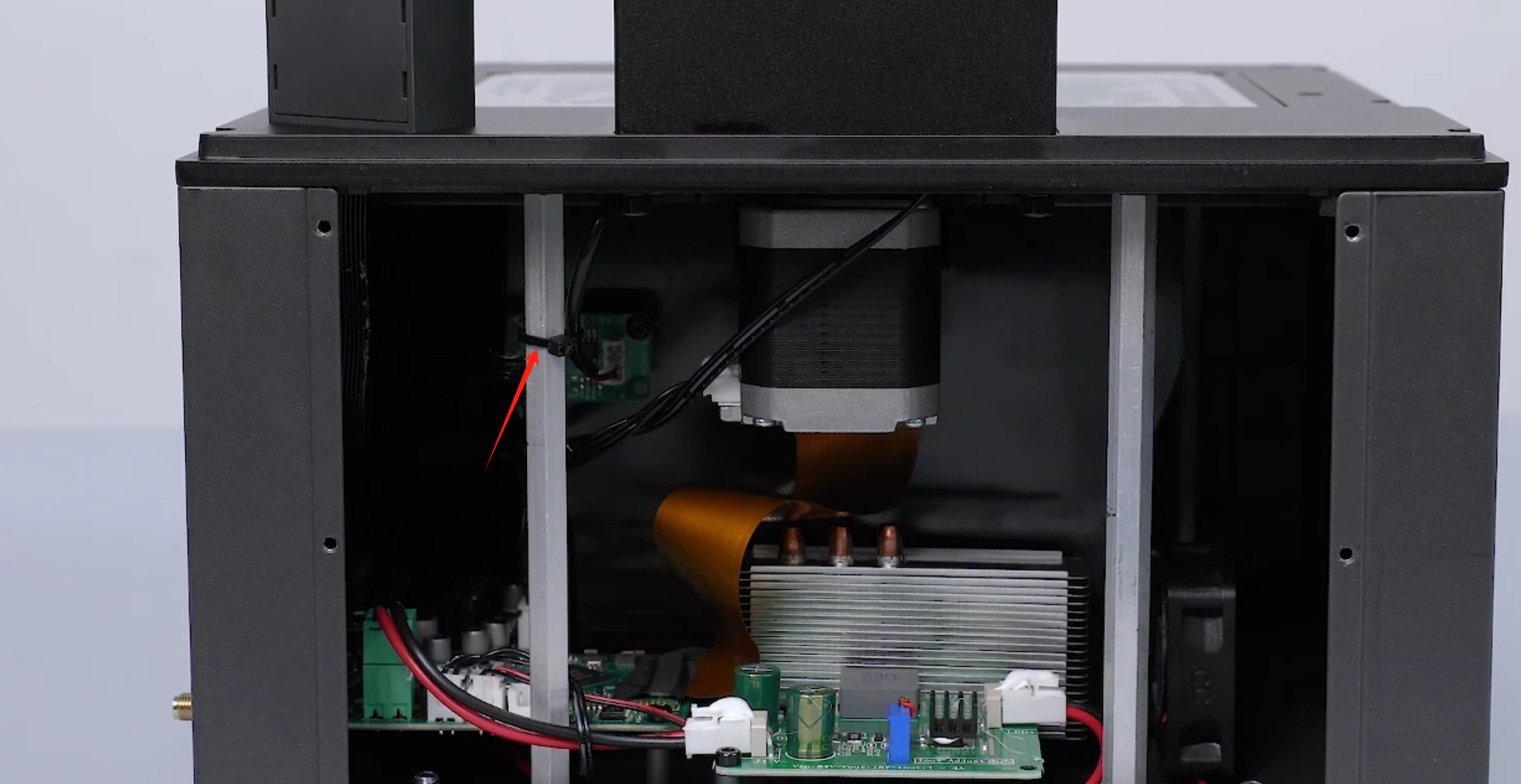

- Use a pair of diagonal pliers to cut off the cable ties securing the spring (the left picture), then unplug the ribbon cables of the spring port of the adpater board (the right picture).

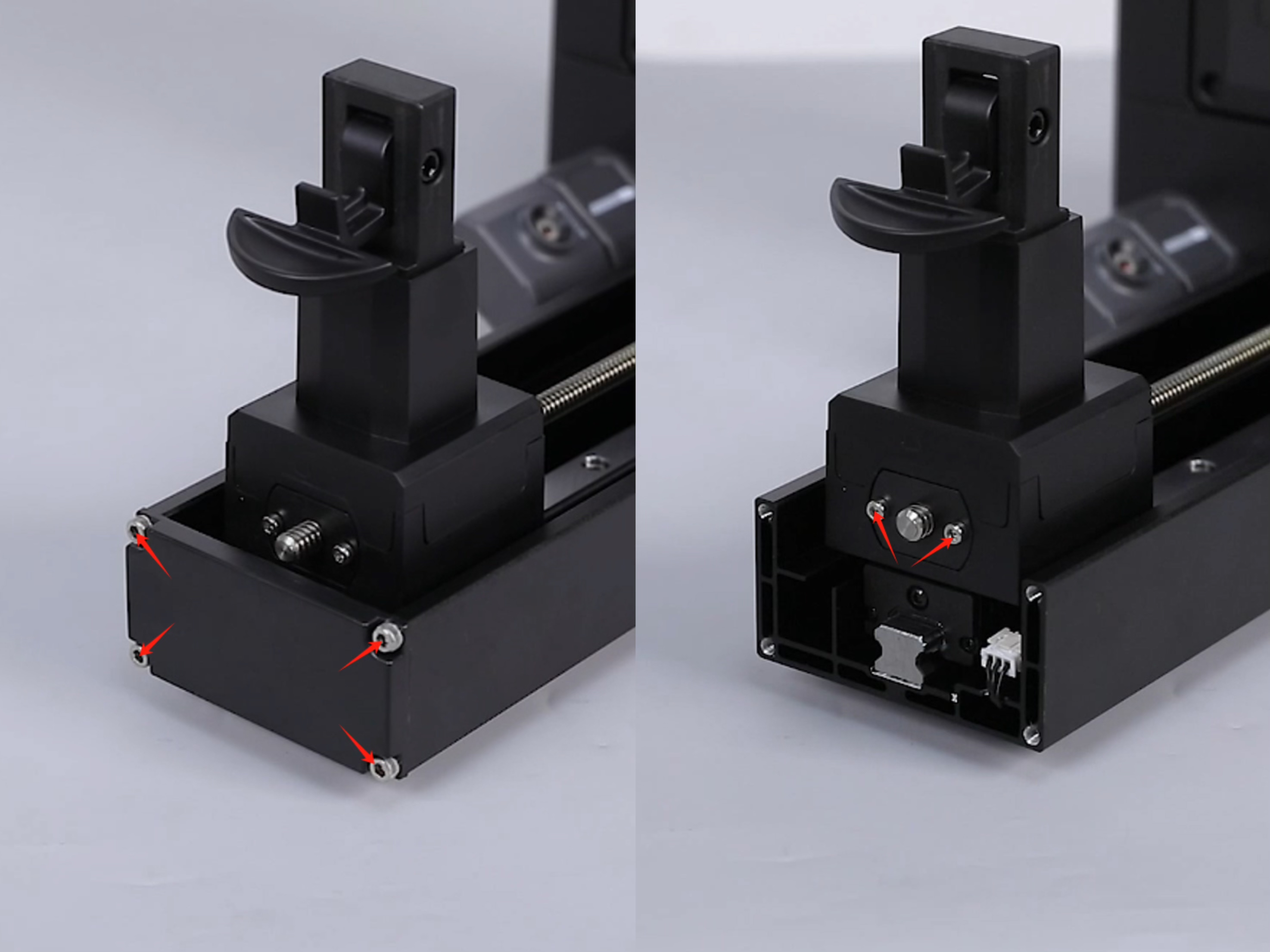

- Use a 3.0 mm Allen wrench to loosen the 4 screws securing Z-axis damper, then remove the damper.

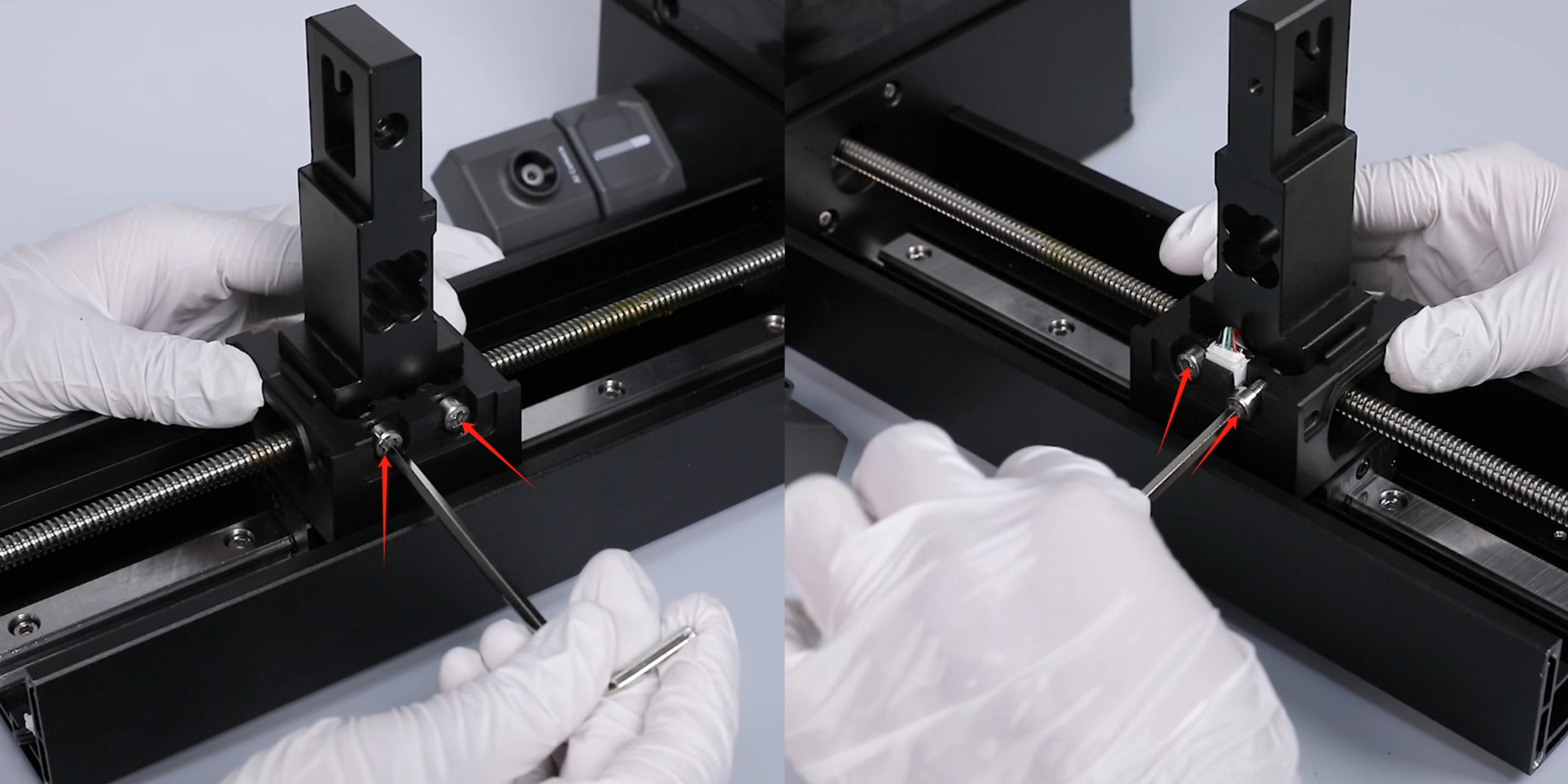

- Use a 2.5 mm Allen wrench to loosen the 2 screws securing the lead screw nut.

- Hold the lead screw with one hand and turn the nut with the other hand to remove it from the top of the lead screw.

- Use a pair of diagonal pliers to cut the hot glue at the limit switch port.

- Use a 2.5 mm Allen wrench to loosen the 2 screws securing the Z-axis limit switch.

- Remove the Z-axis limit switch, then unplug the ribbon cables of the Z-axis limit switch.

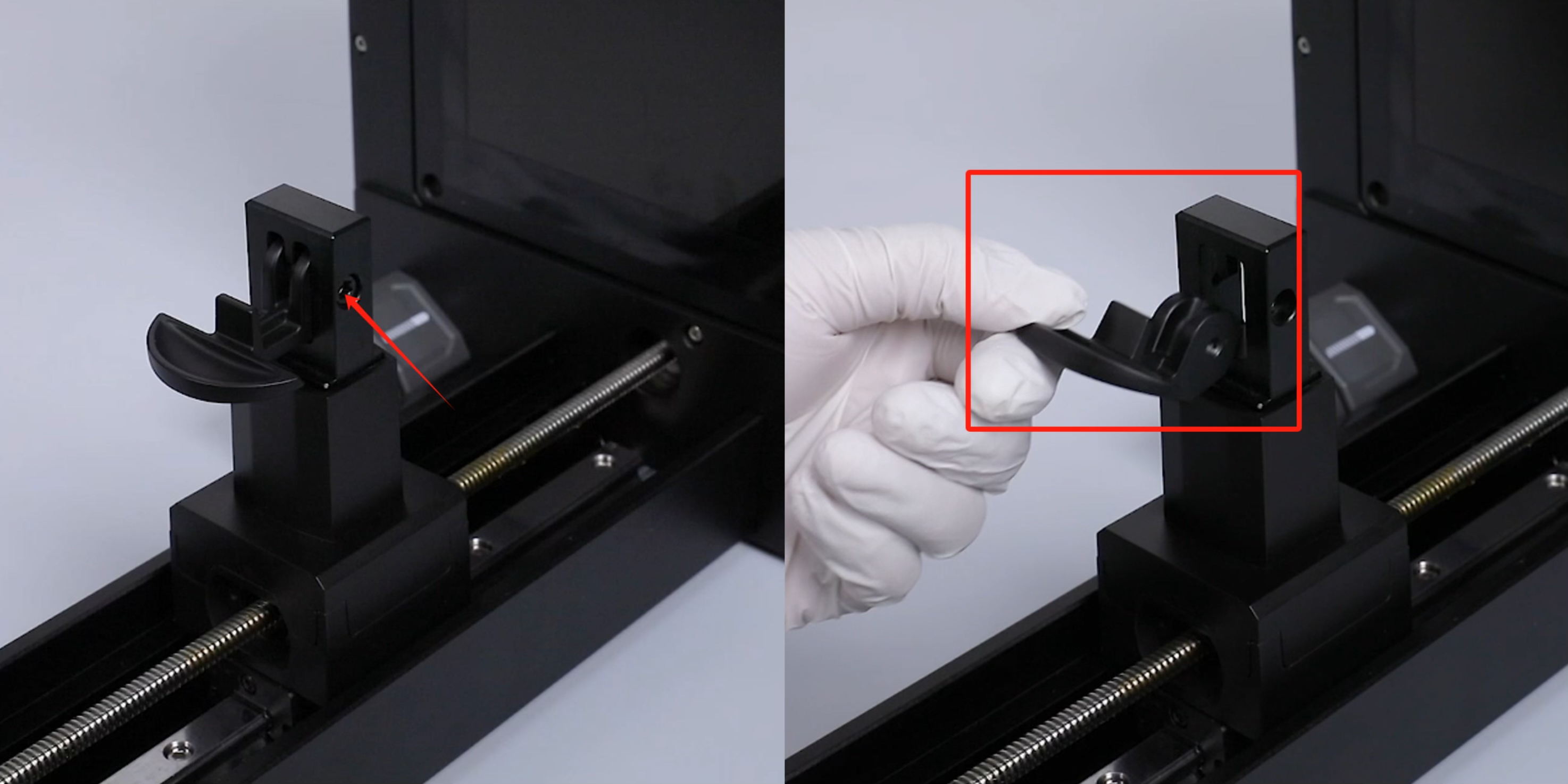

- Use a 4.0 mm Allen wrench to loosen the screw securing handle (the left picture), then remove the handle.

- Remove the protective cover by gently pulling outward.

- Use a 4.0 mm Allen wrench to loosen the 4 screws securing the cantilever junction blocks.

Note: Use a hair dryer to make it easier to loosen the screws, where the adhesive is applied to the front.

- Lift up the front cantilever beam to remove it.

Note: There are mechanical sensor cables. Handle with caution.

- Use a 3.0 mm Allen wrench to loosen the 4 screws securing the cantilever.

- Remove the Z-axis cantilever from above the printer's Z-axis.

- Remove the spring wire from the spring slot.

- Use a pair of diagonal pliers to cut off the cable ties securing the spring.

- Use a pair of diagonal pliers to cut the hot glue at the spring port (the left picture), then unplug the ribbon cable port of the mechnical sensor (the right picture).

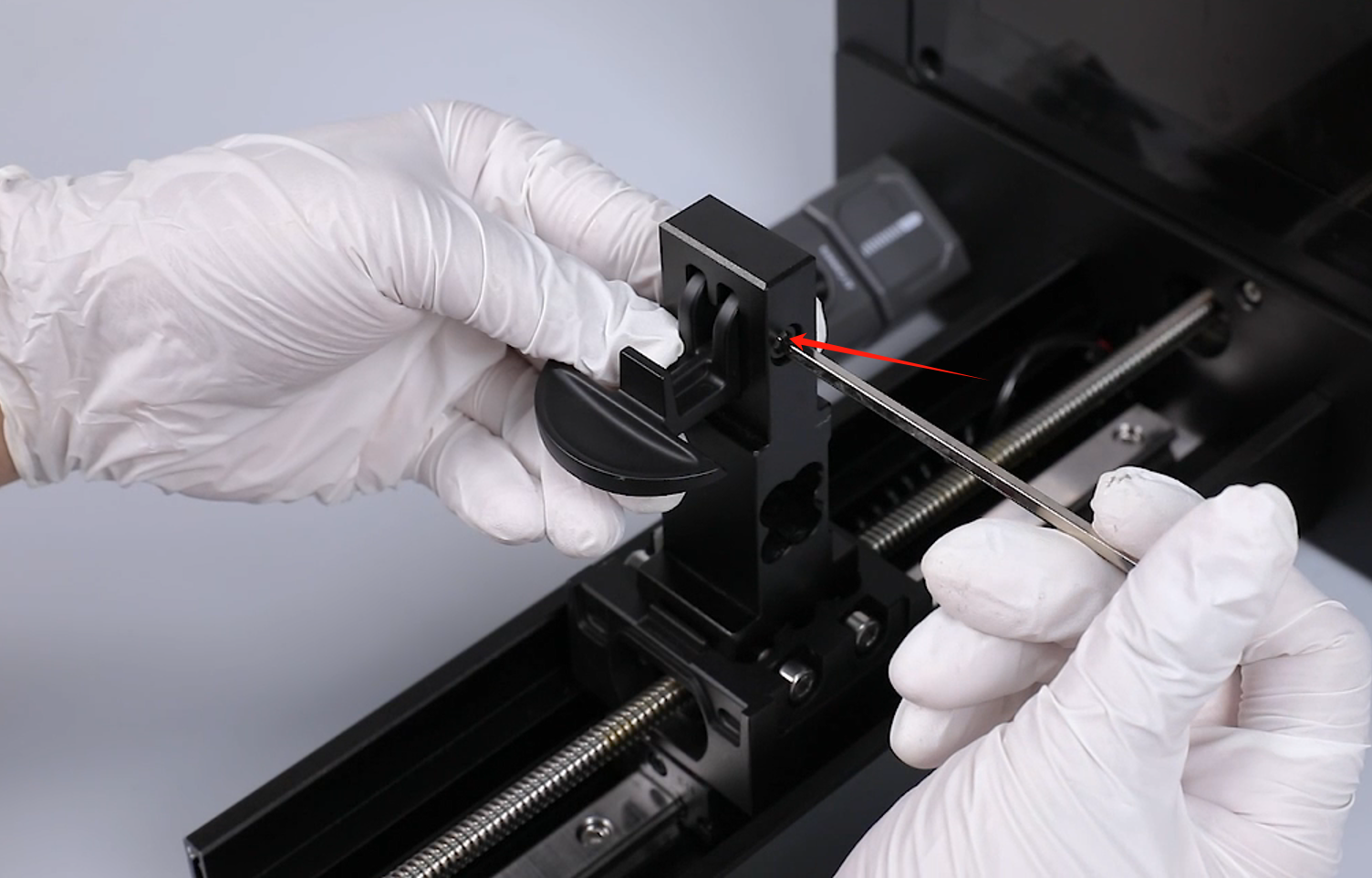

- Use an Allen wrench to eject the female terminal of the spring (the left picture), then remove the old spring (the right picture).

¶ Install the new spring

- Prepare the new spring. Pass the female terminal of the spring wire through the ribbon cable holes to put the terminal in the installation position. Press down lightly to secure the port.

- Insert the ribbon cables of the mechnical sensor.

- Organize the spring. Use 2 cable ties to secure the spring wires.

- Insert the spring into the wire slot.

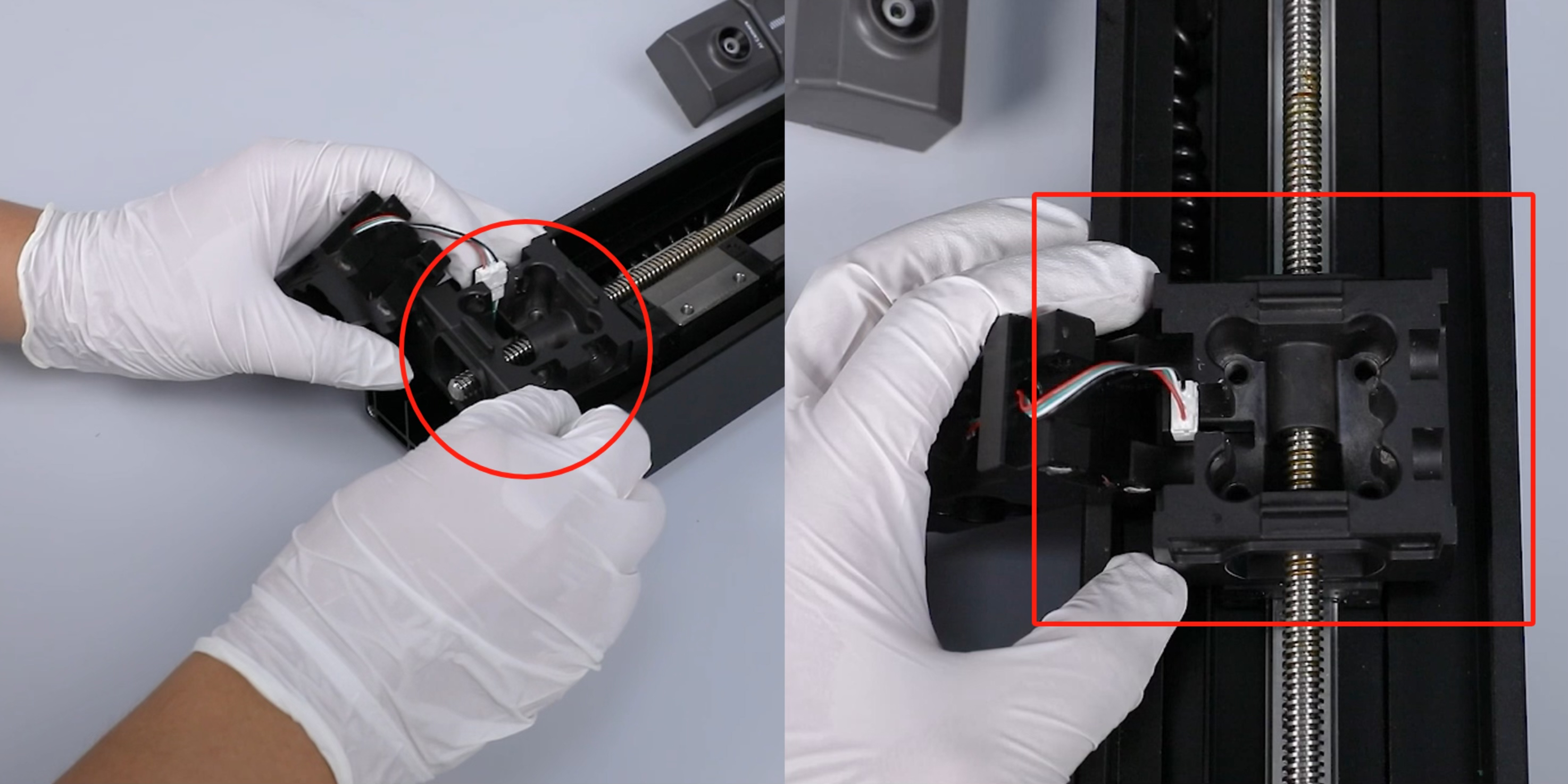

- Pass the spring through lead screw. Put the Z-axis cantilever in the installation position (the right picture) by aligning the cantilever with the screw holes on the sliding block.

- Use a 3.0 mm Allen wrench to secure 4 screws securing the cantilever by three-quarters of the required torque. After installing all screws, tighten the screws completely.

- Put the front cantilever beam in the installation position by aligning it the the screw holes.

Note: The mechnical sensor should be installed towards the LCD screen. Do not press the connecting wires.

- Use a 4.0 mm Allen wrench to tighten the 4 screws securing the cantilever junction blocks by three-quarters of the required torque.

Note: Do not tighten the 4 screws completely until leveling the printer.

- Put the handle in the installation position by aligning it with the screw holes. Use a 4.0 mm Allen wrench to tighten the screw securing the handle.

Note: Do not use the protective cover until leveling the printer.

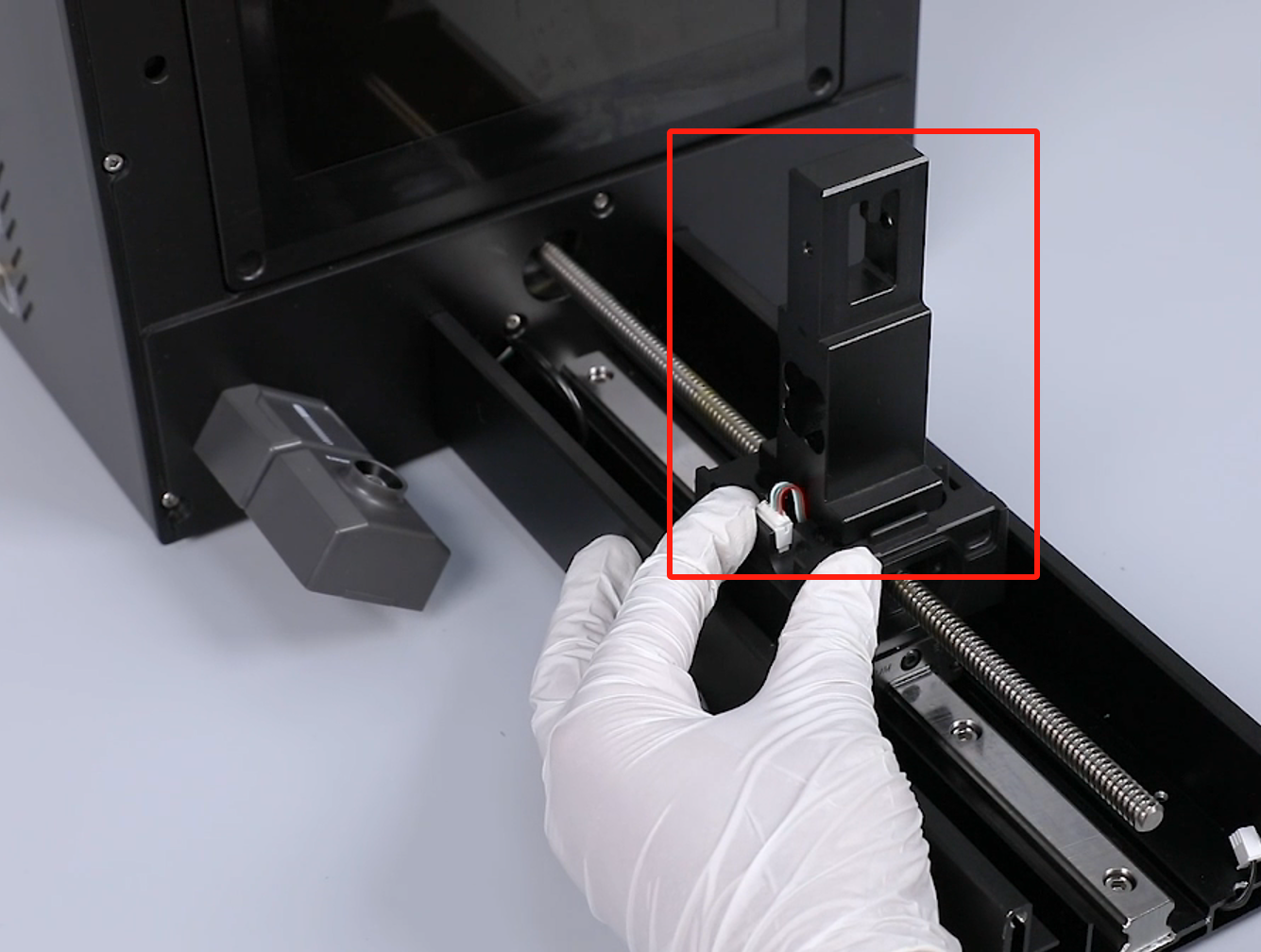

- Use a pair of tweezers to feed the spring port through the ribbon cable hole (the left picture) to the bottom of the printer (the right picture).

- Prepare the Z-axis limit switch. Put it in the installation position by aligning it with the screw holes. Use a 2.5 mm Allen wrench to tighten the 2 screws securing the Z-axis limit switch.

- Plug the ribbon cables of the Z-axis limit switch (the right picture).

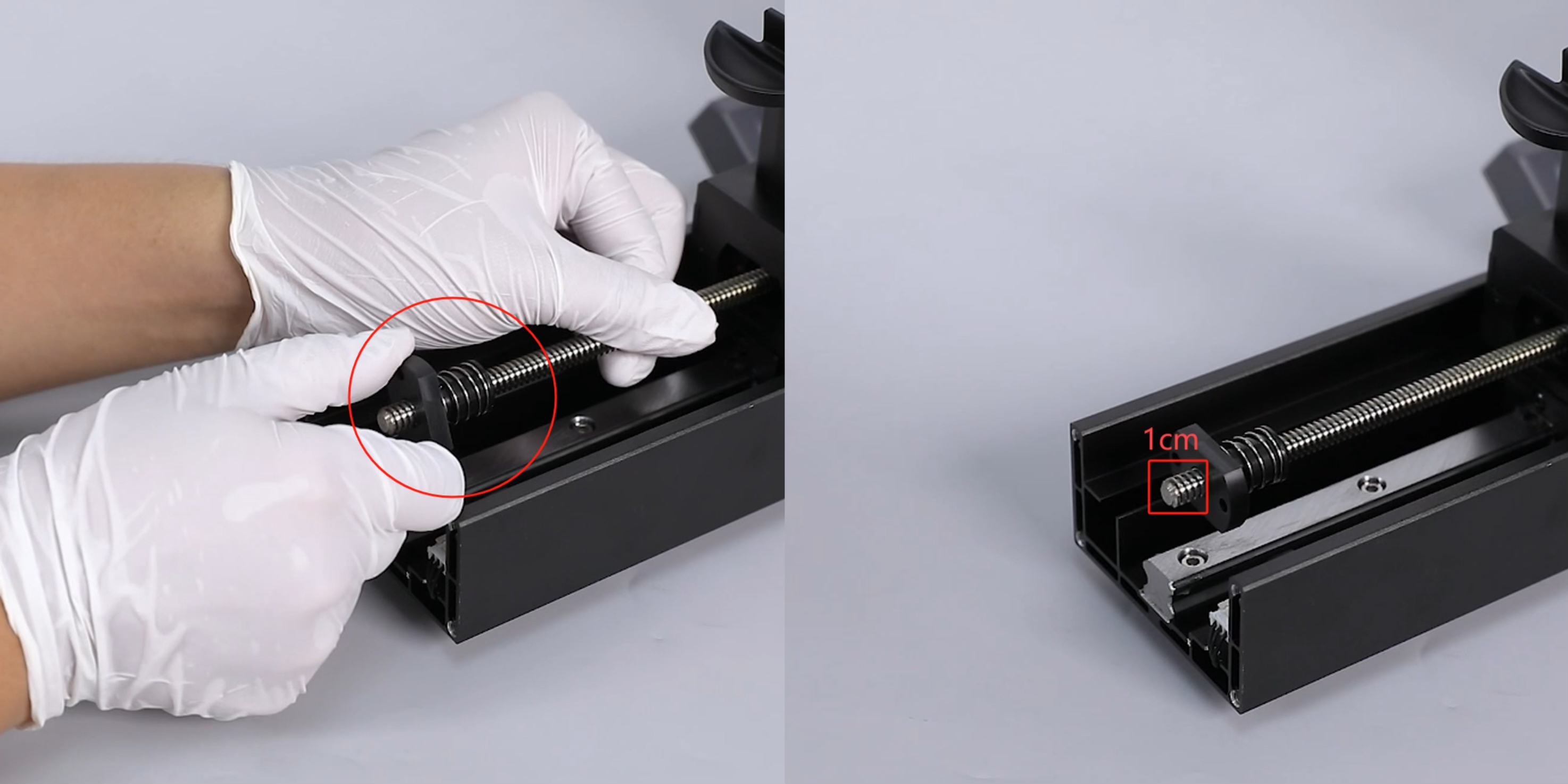

- Hold the lead screw with one hand and turn the nut with the other hand to install the nut from the top of the lead screw (the left picture).

- Screw the nut to about 1 cm from the top of the lead screw (the right picture).

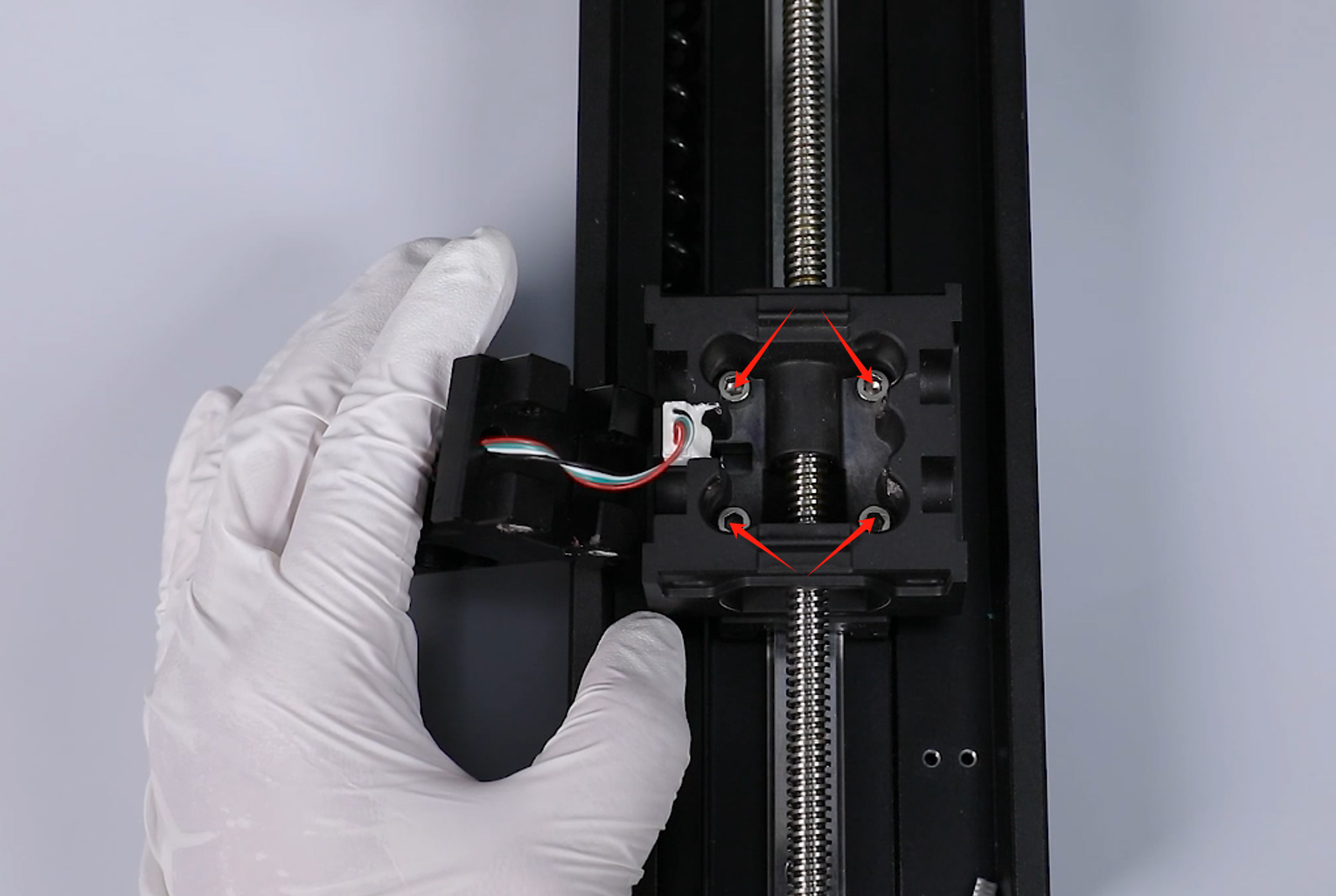

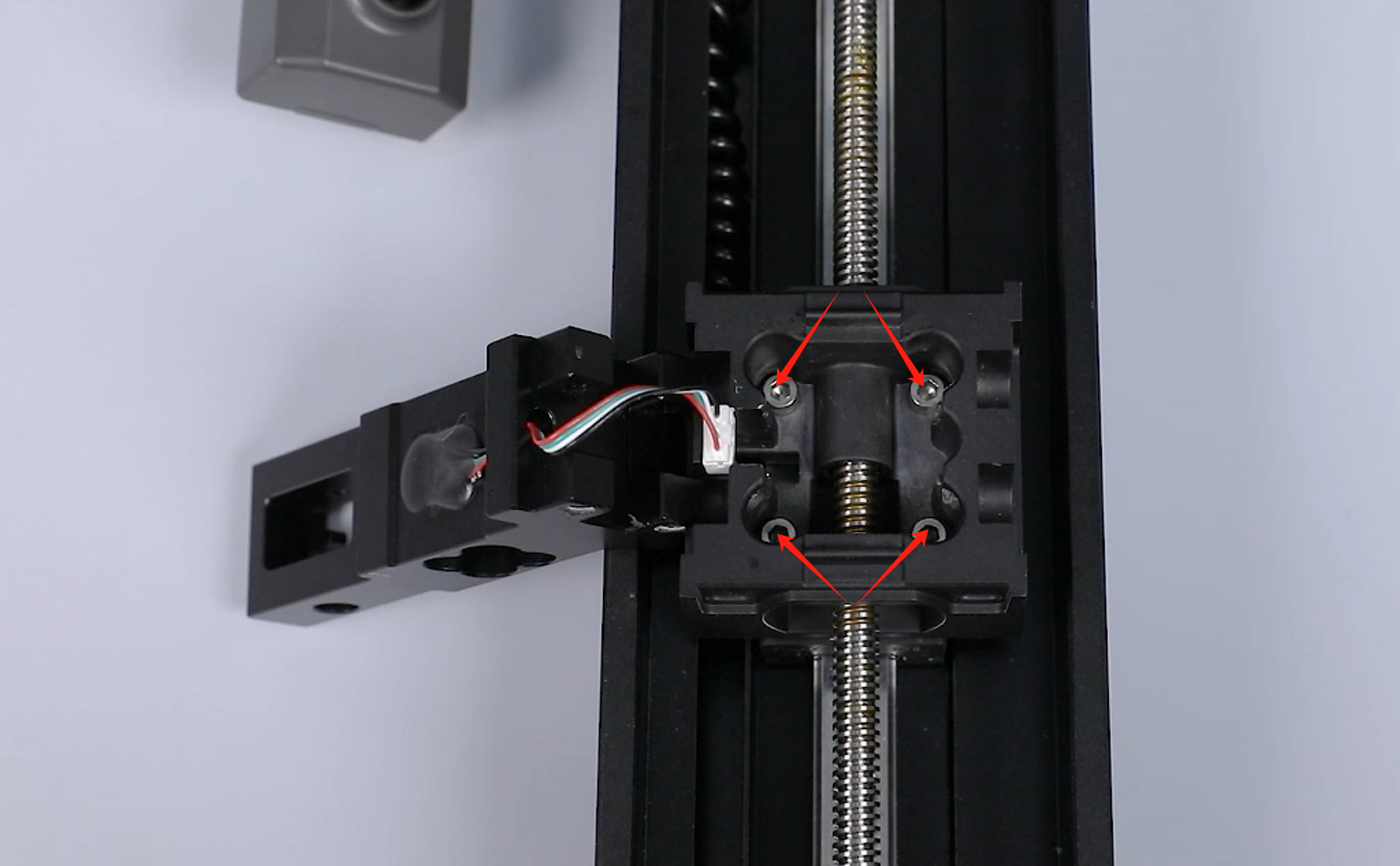

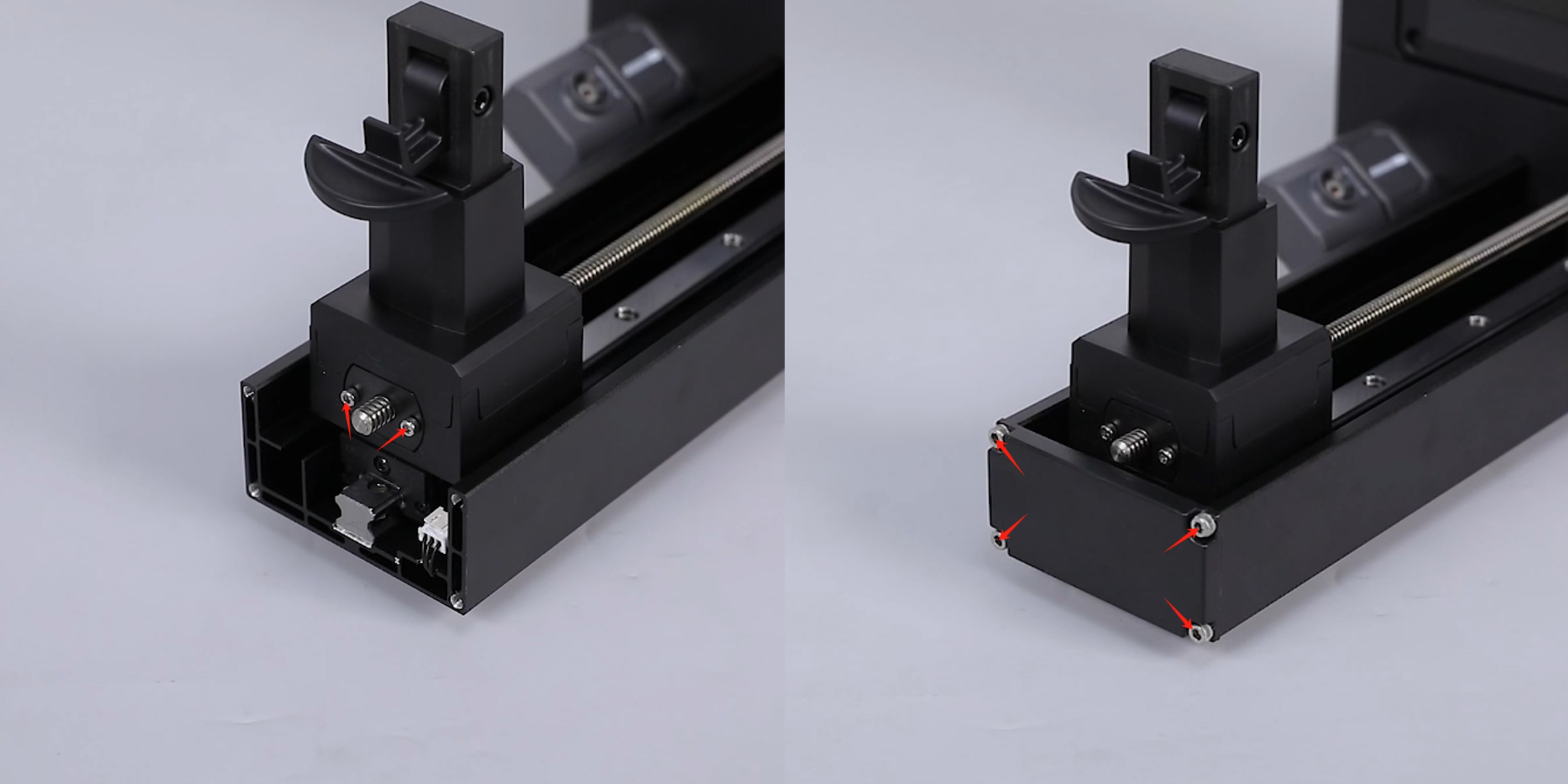

- Push the cantilever to align with the screw holes of the lead screw nut. Use an 2.5 mm Allen wrench to screw 2 securing screws by three quarters of the required torque (the left picture).

Note: The 2 screws should be tighten completely subsequently. - Prepare the damper. Use a 3.0 mm Allen wrench to tighten the 4 screws securing Z-axis damper.

- Insert the ribbon cables of the mechnical sensor into the adapter board port. Use cable ties to secure the ribbon cables of the mechnical sensor.

- Prepare the back cover of the printer. Use a 2.0 mm Allen wrench to tighten the 7 screws securing the back cover of the printer.

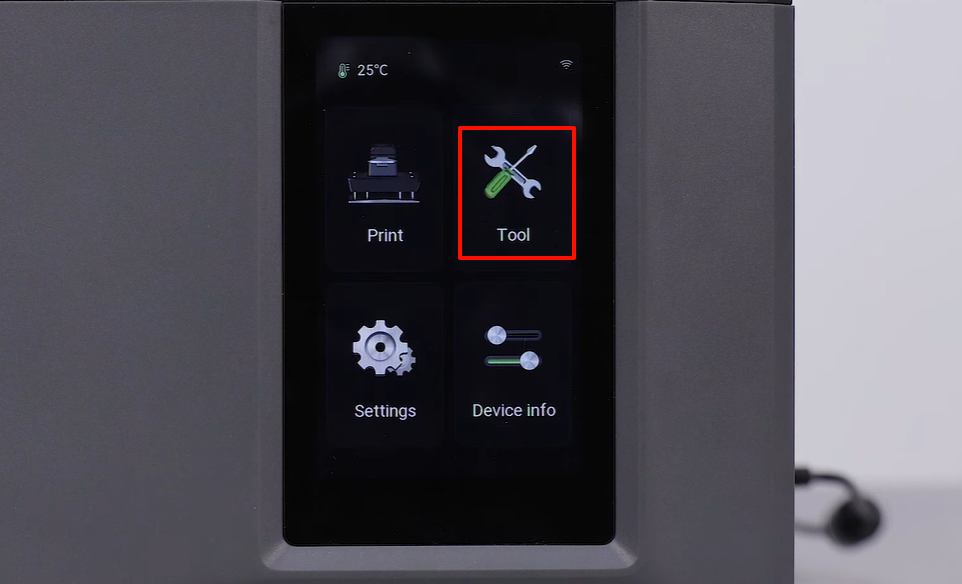

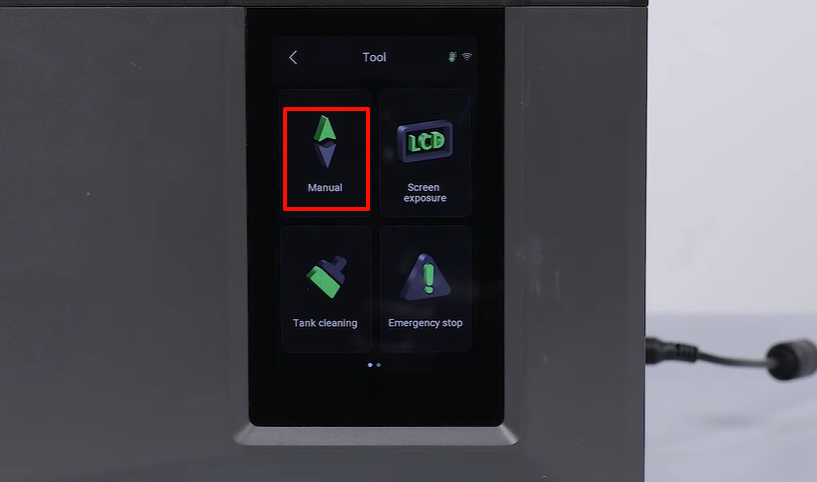

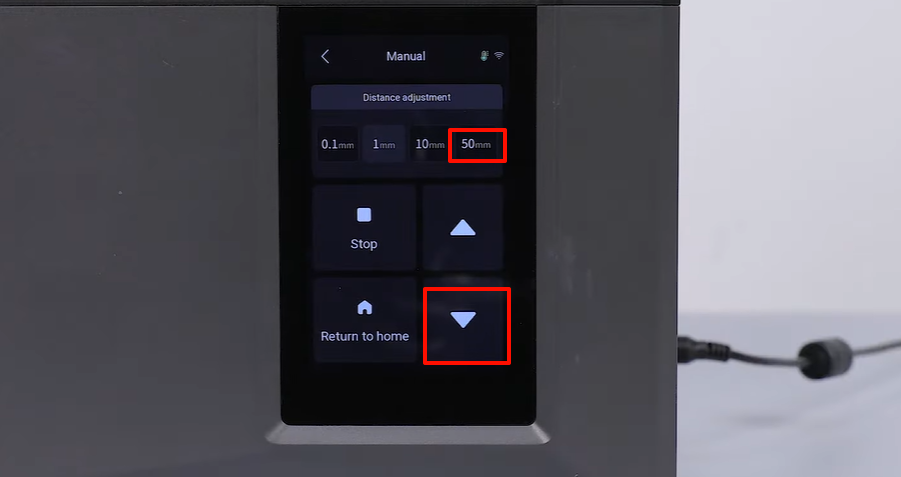

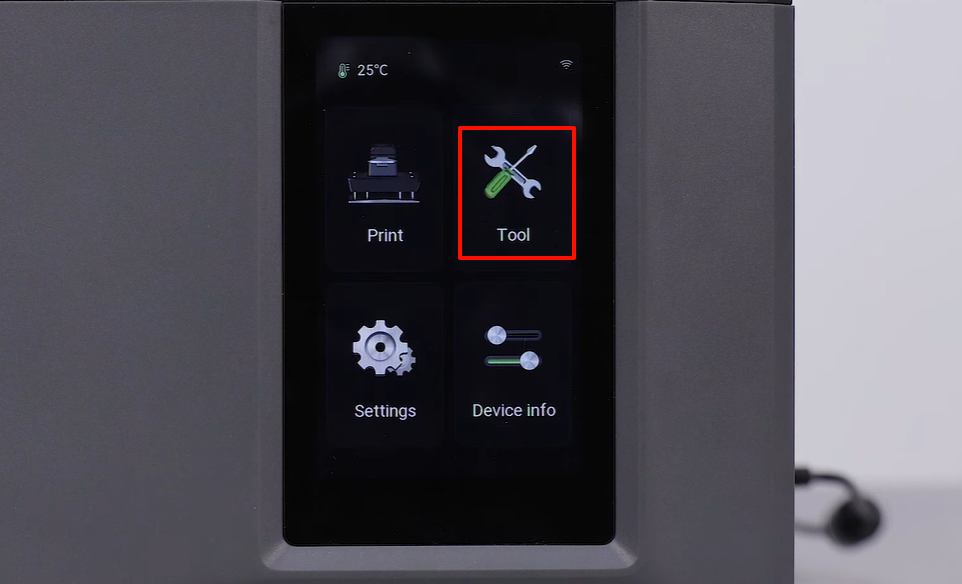

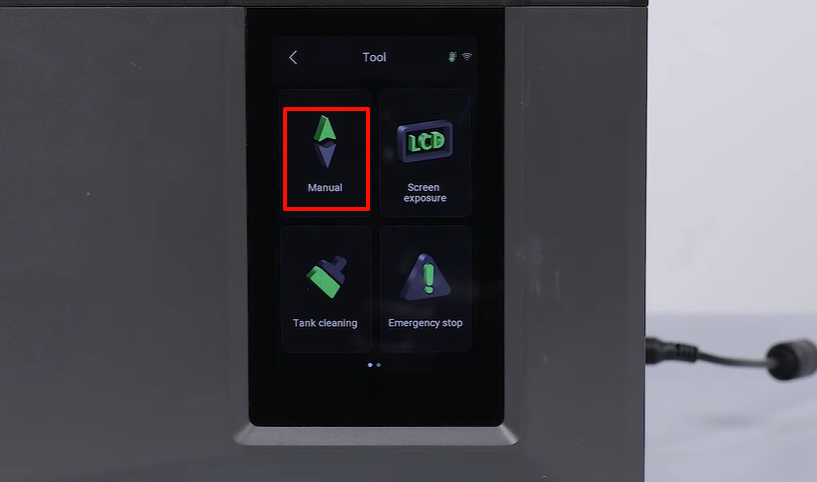

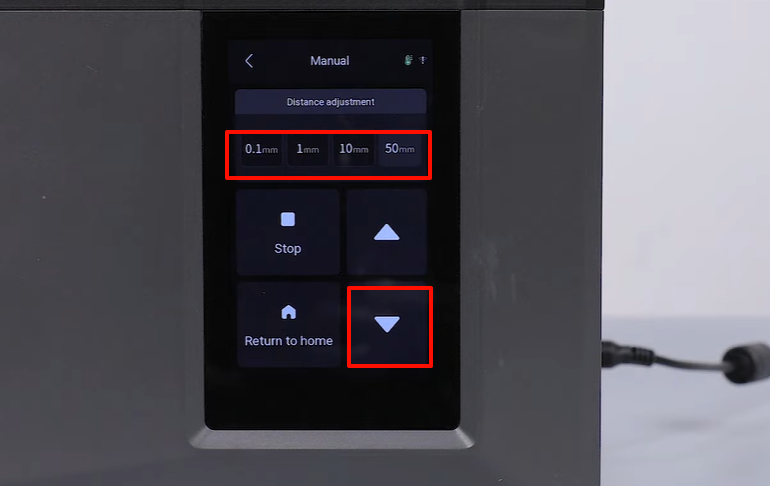

- Power on the printer. Tap "Tools - Manual - 50 mm" to lower the Z-axis.

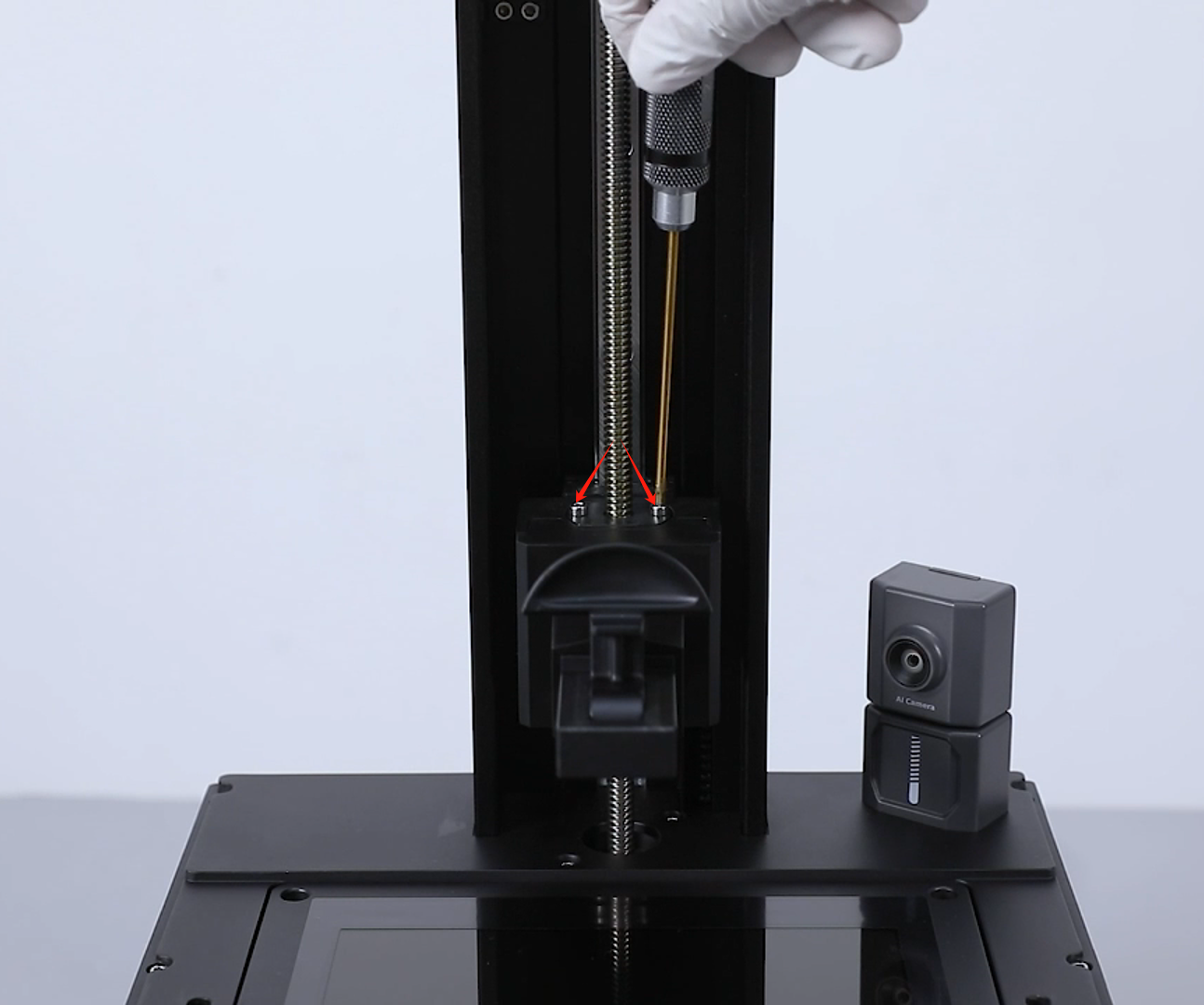

- After the Z-axis lowered to the bottom position, use a 2.5 mm Allen wrench to securely tighten the 2 screws holding the lead screw nut multiple times.

¶ Leveling the Printer

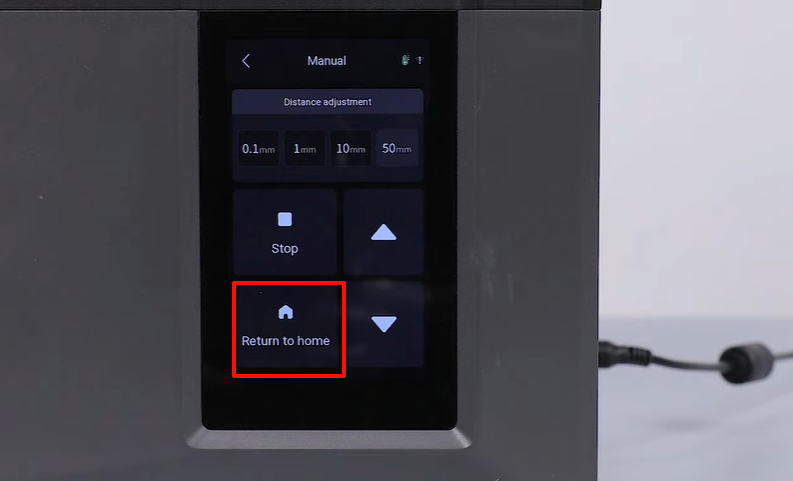

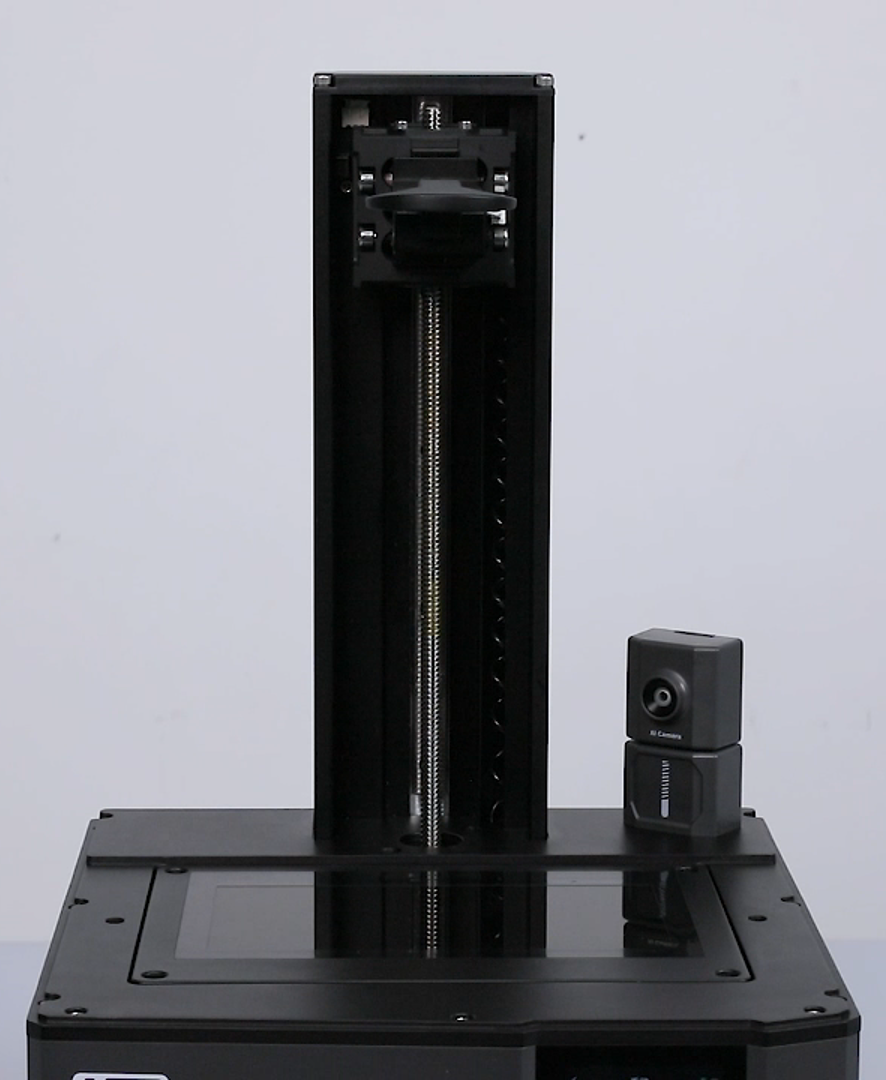

- Tap "Home" on the touchscreen, the Z-aixs starts its homing process.

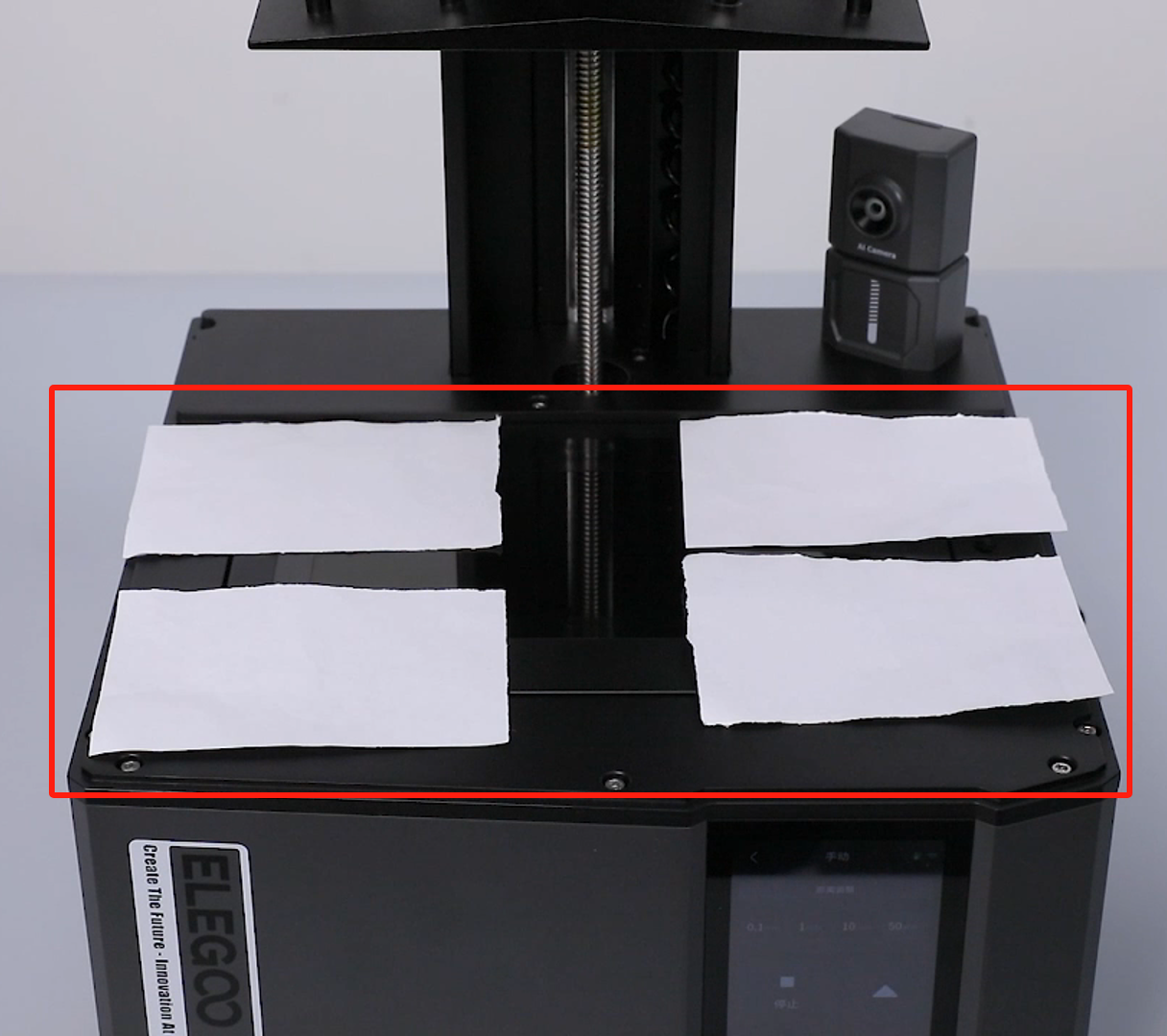

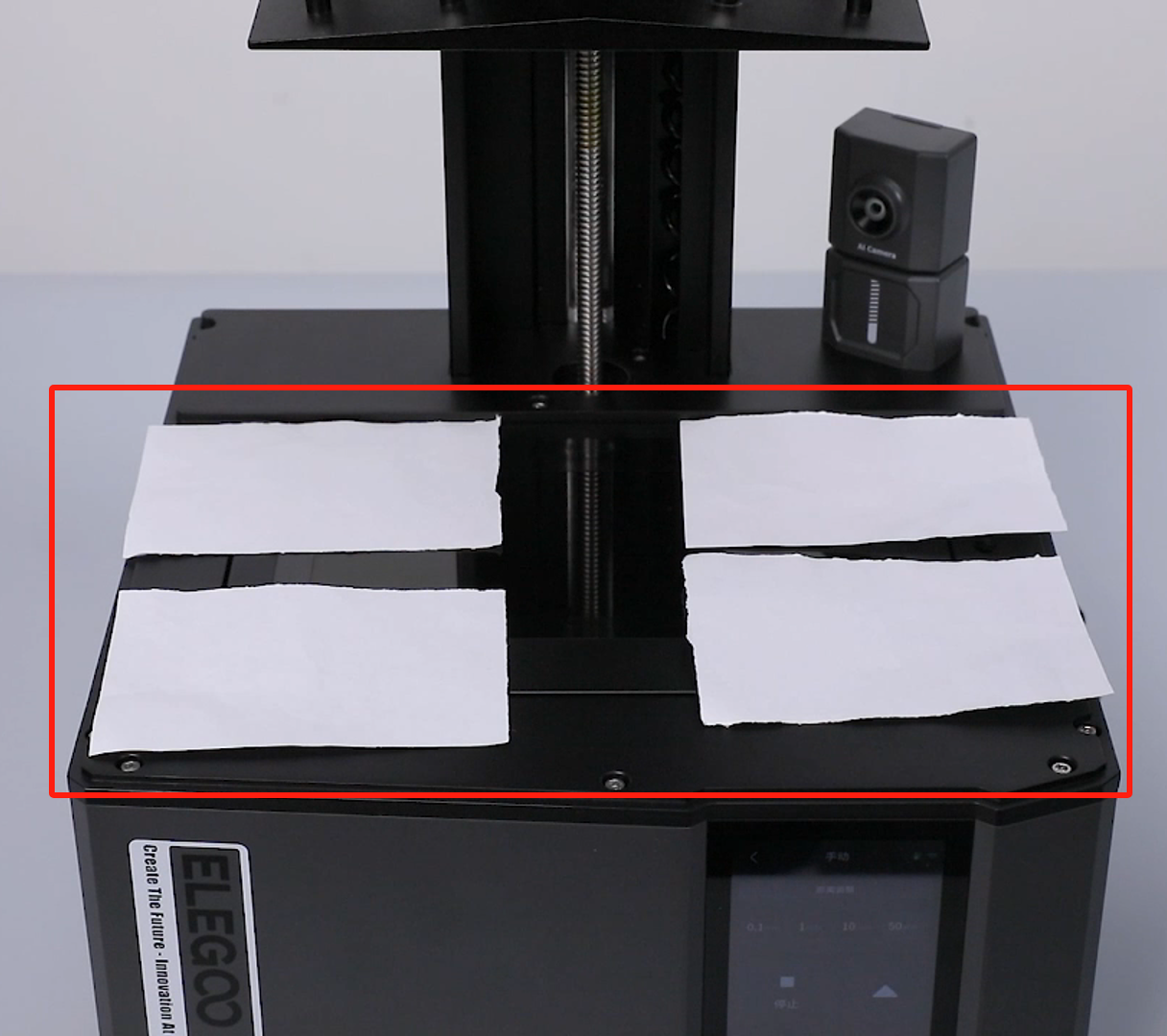

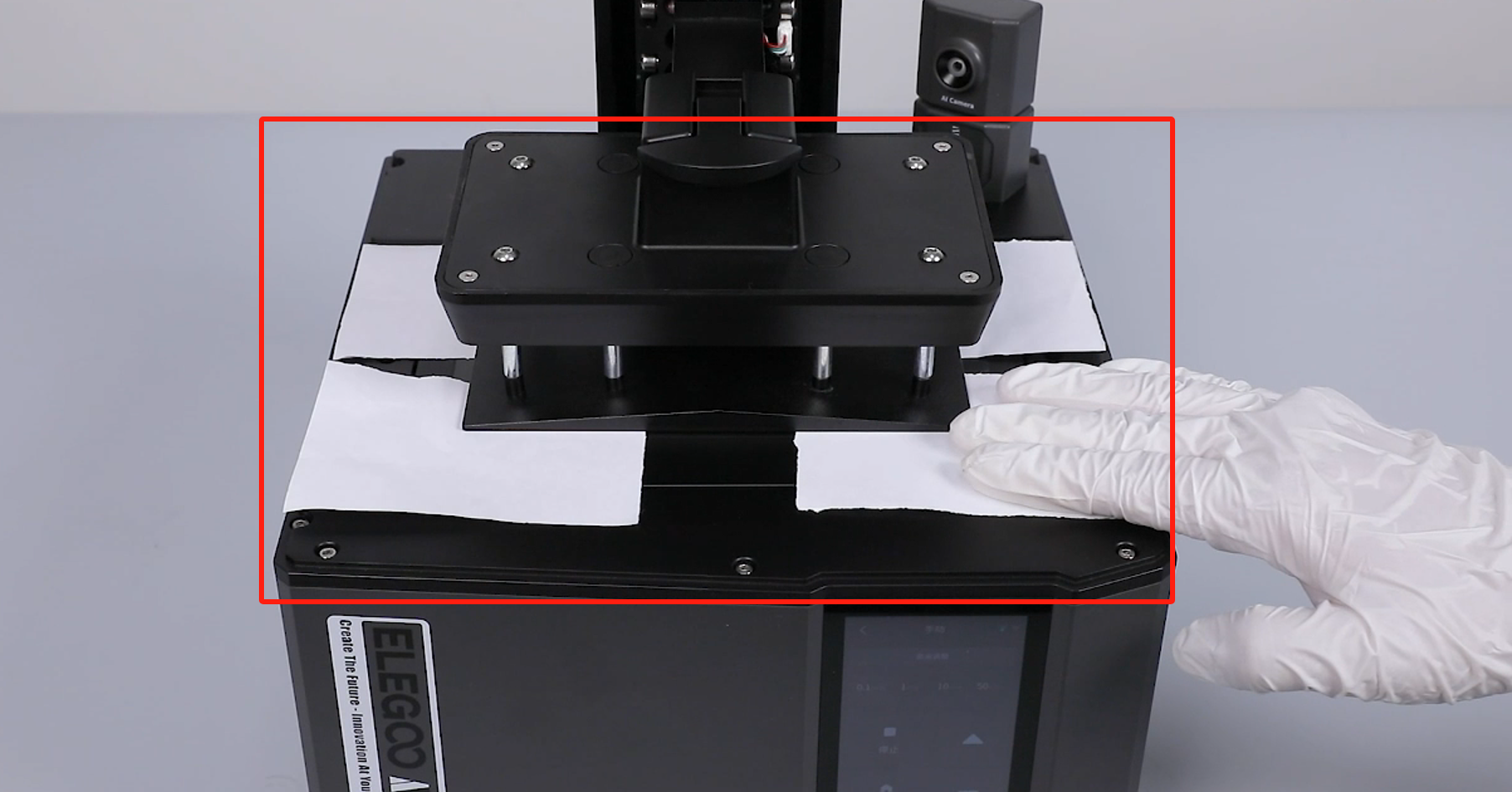

- Install the printing platform. Tear a piece of A4 paper into 4 equal pieces and place them at the four corners of the LCD screen.

- Tap "Tools - Manual" on the touchscreen. Lower the printimg platform by 50 mm, 10 mm, 1 mm and 0.1 mm to press the A4 paper.

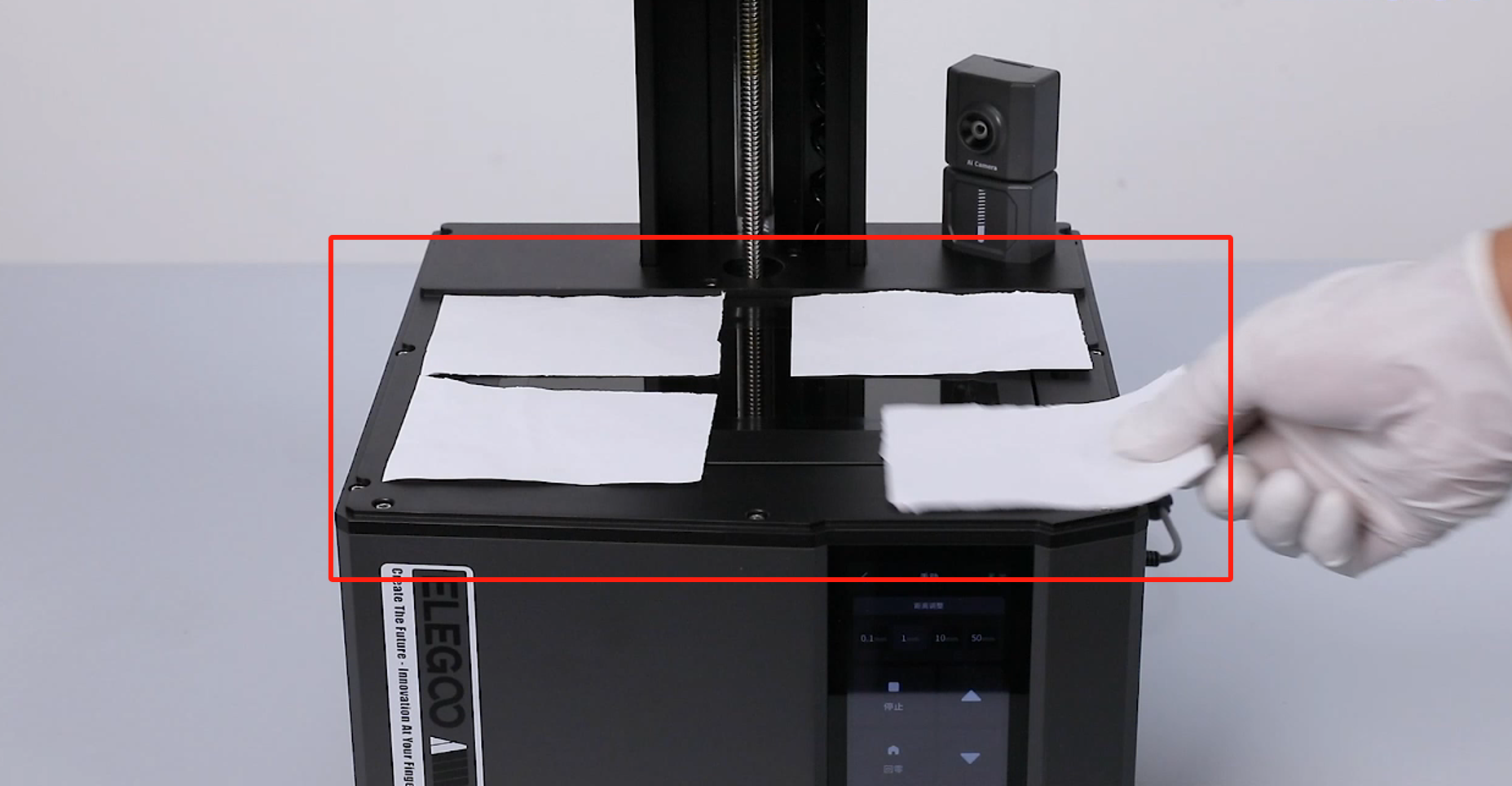

- Pull the A4 paper at the 4 corners by hand to make sure there is significant resistance to the A4 paper.

- Use a 4.0 mm Allen wrench to tighten the 4 screws in diagonal direction securing the cantilever junction blocks.

- Tap "Home" on the touchscreen, the Z-aixs starts its homing process. Then, remove the A4 paper.

- Remove the printing platform. Use a 4.0 mm Allen wrench to loosen the screw securing handle, then remove the handle.

- Align the clips and press the protective cover back into place.

- Put the handle in the installation position by aligning it with the screw holes. Use a 4.0 mm Allen wrench to tighten the screw securing the handle.

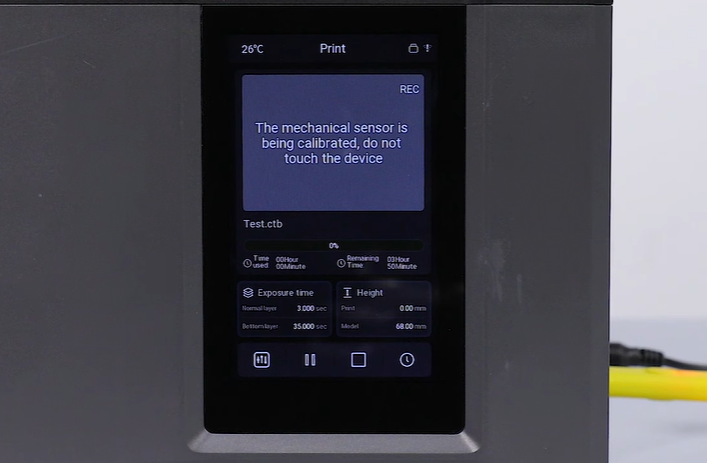

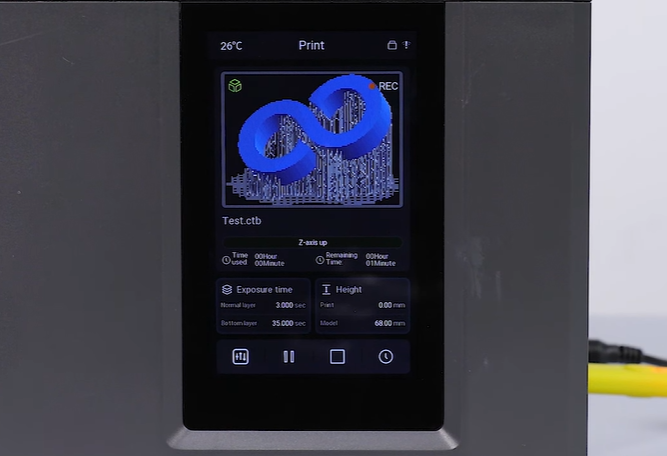

¶ Printing Test

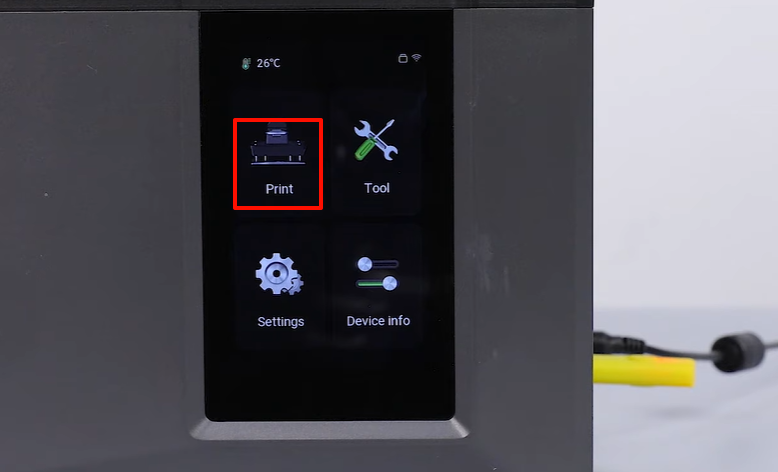

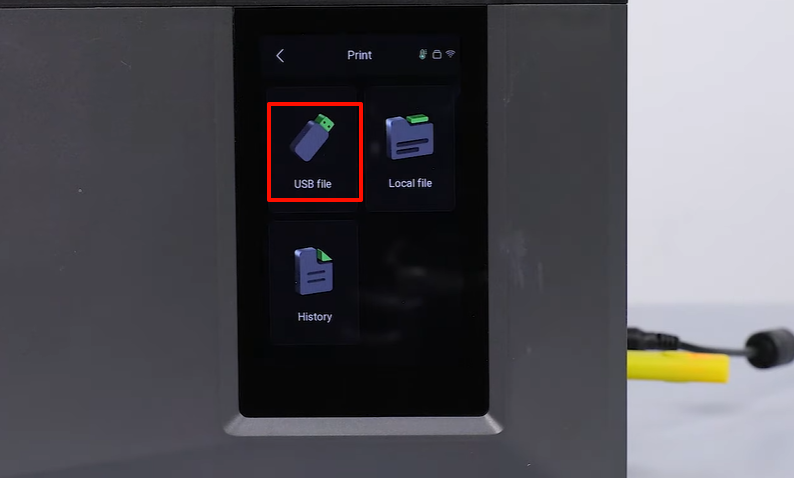

- After installing the printing platform and resin tank, touch "Print - USB file" on the touchscreen and select the model to be printed.

- Observe the touchscreen. It displays "Calibrating the sensor - detecting resin - automatic leveling" and function detection is normal without any abnormal alarm. It indicates that the spring replacement and leveling compeltes. The printer is ready for use.