Lead screw Routine Maintenance

Regular maintenance and upkeep can ensure the normal operation of the 3D printer lead screw and improve the print quality and stability (It is recommended to perform maintenance once every two months).

Precautions

When maintaining the 3D printer, be sure to disconnect the power supply first.

Tools needed

●Dust-free cloth

●Paper towel

●Lead screw cleaning tool (self-printed)

●White lithium grease

●Cotton swab

Reference video

Operation steps

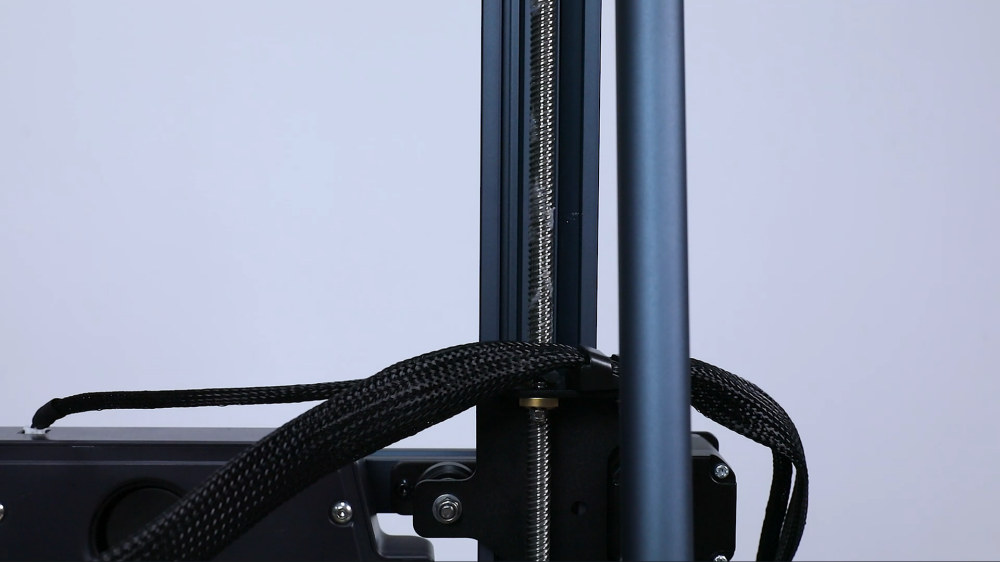

1. Put the dust-free cloth on the surface of the lead screw, and use the lead screw cleaning tool to clamp the dust-free cloth.

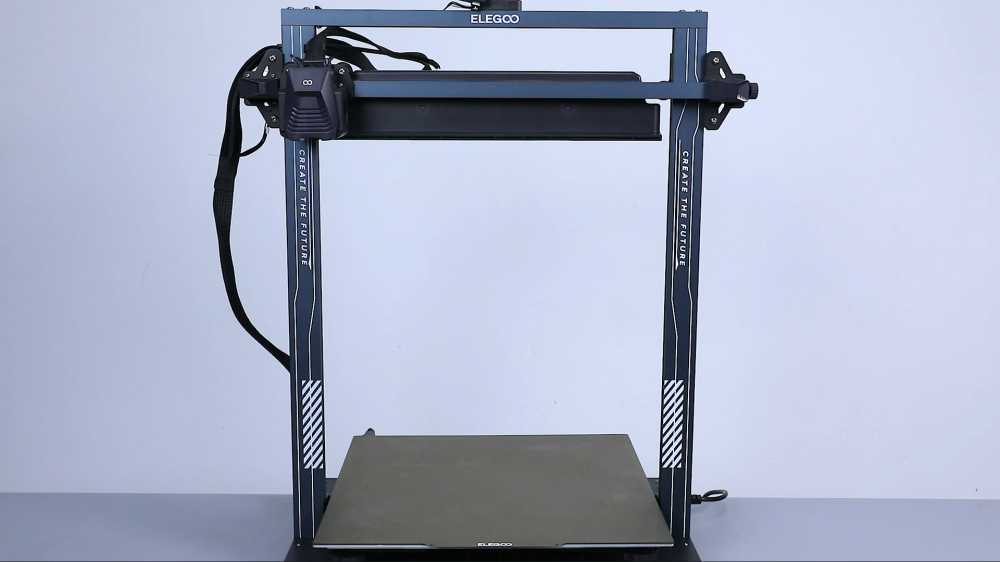

2. Hold the lead screw cleaning tool with one hand, and pull the timing belt on the top of the printer with the other hand to raise the Z-axis. The lead screw cleaning tool will hold the dust-free cloth and rise synchronously to wipe away the dust and oil on the surface of the lead screw. (Same operation method for the lead screw on the right side).

3. Pull the timing belt in the opposite direction, the Z-axis will move downward, and the lead screw cleaning tool will hold the dust-free cloth and descend synchronously to wipe the dust and oil on the surface of the lead screw. (The same operation method for the lead screw on the right side).

4. After cleaning, use a cotton swab to evenly apply white lithium grease on the surface of the lead screw. (Just lubricate an appropriate amount of lubricant. Excessive lubrication may cause the adsorption of dust and particles, forming dirt).

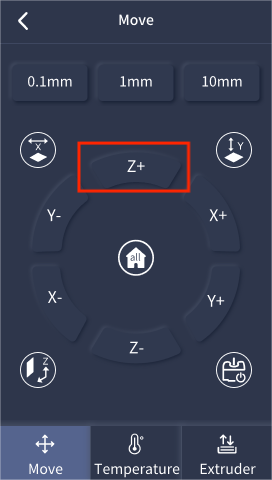

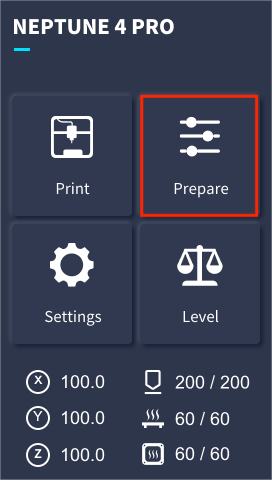

5. Power on the printer, click the [Prepare]-[Return to Zero] (return to home) button on the touch screen, and the printer will perform a homing movement.

6.Then operate the Z-axis on the touch screen to rise to the highest point several times, and then click the screen again to return to zero so that the Z-axis,moves reciprocately up and down to make the grease more evenly distributed.