Tools and materials needed

●H2.0 Allen wrench

●H2.5 Allen wrench

●H3.0 Allen wrench

●10mm open-end wrench

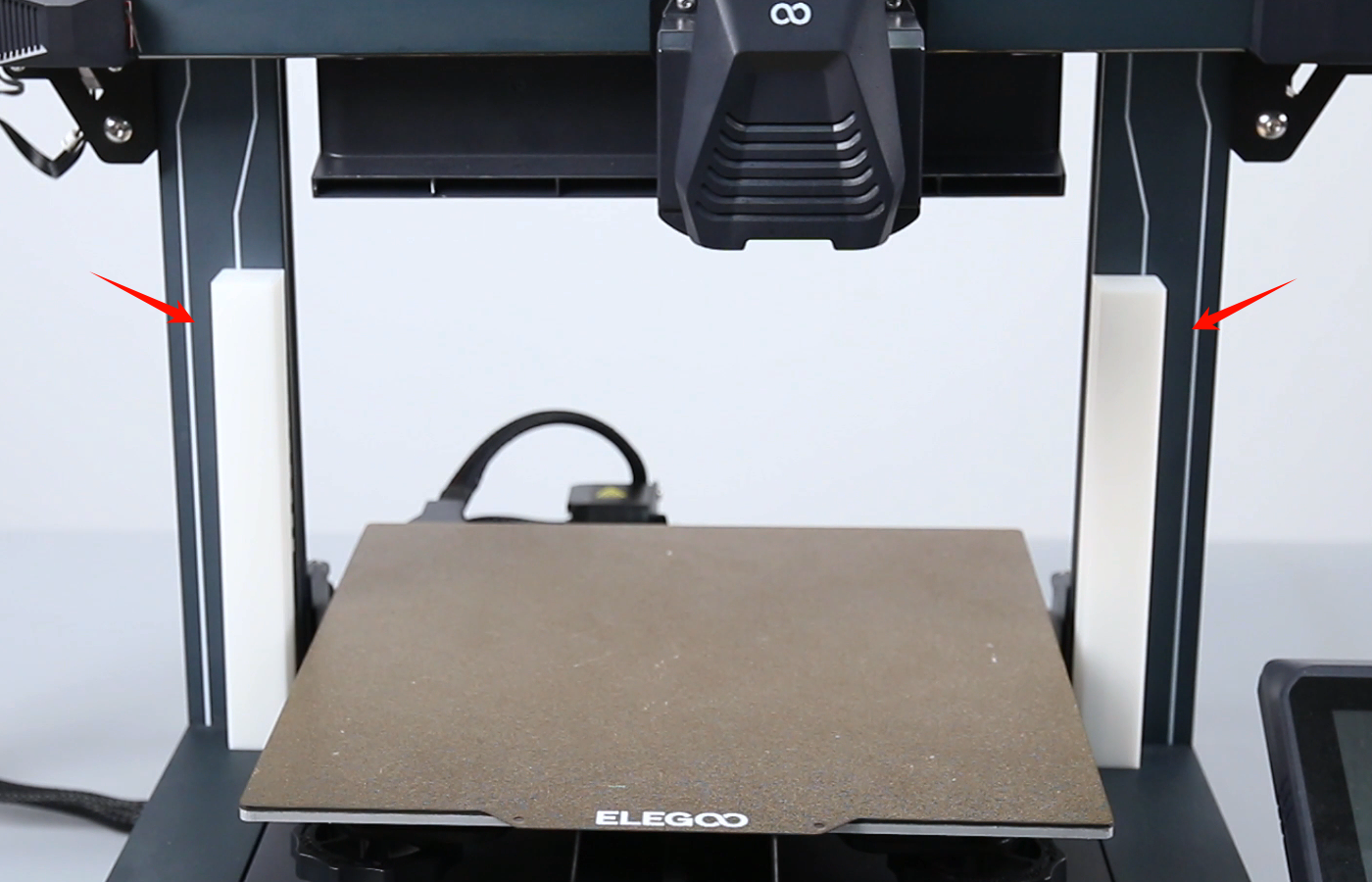

●Two columns of equal height (you can print your own)

Column model file

Precautions

When adjusting the Z-axis eccentric wheels on both sides, no matter how you adjust them, one of the wheels is in a loose state.

Reference video

Operation steps

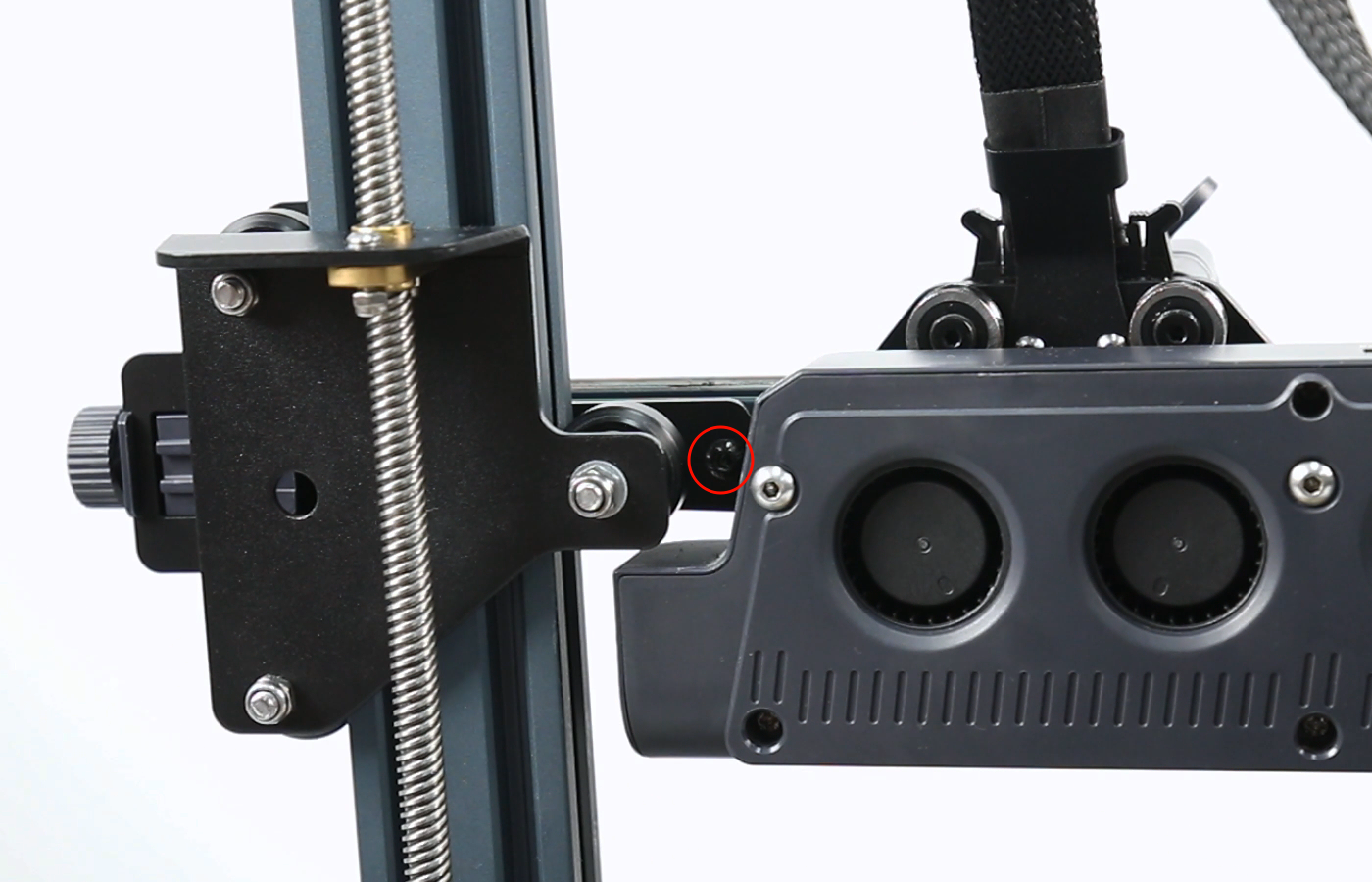

1. Use an H2.5 Allen wrench to loosen the three screws fixed behind the X-axis aluminum profile (loosen without removing the screws).

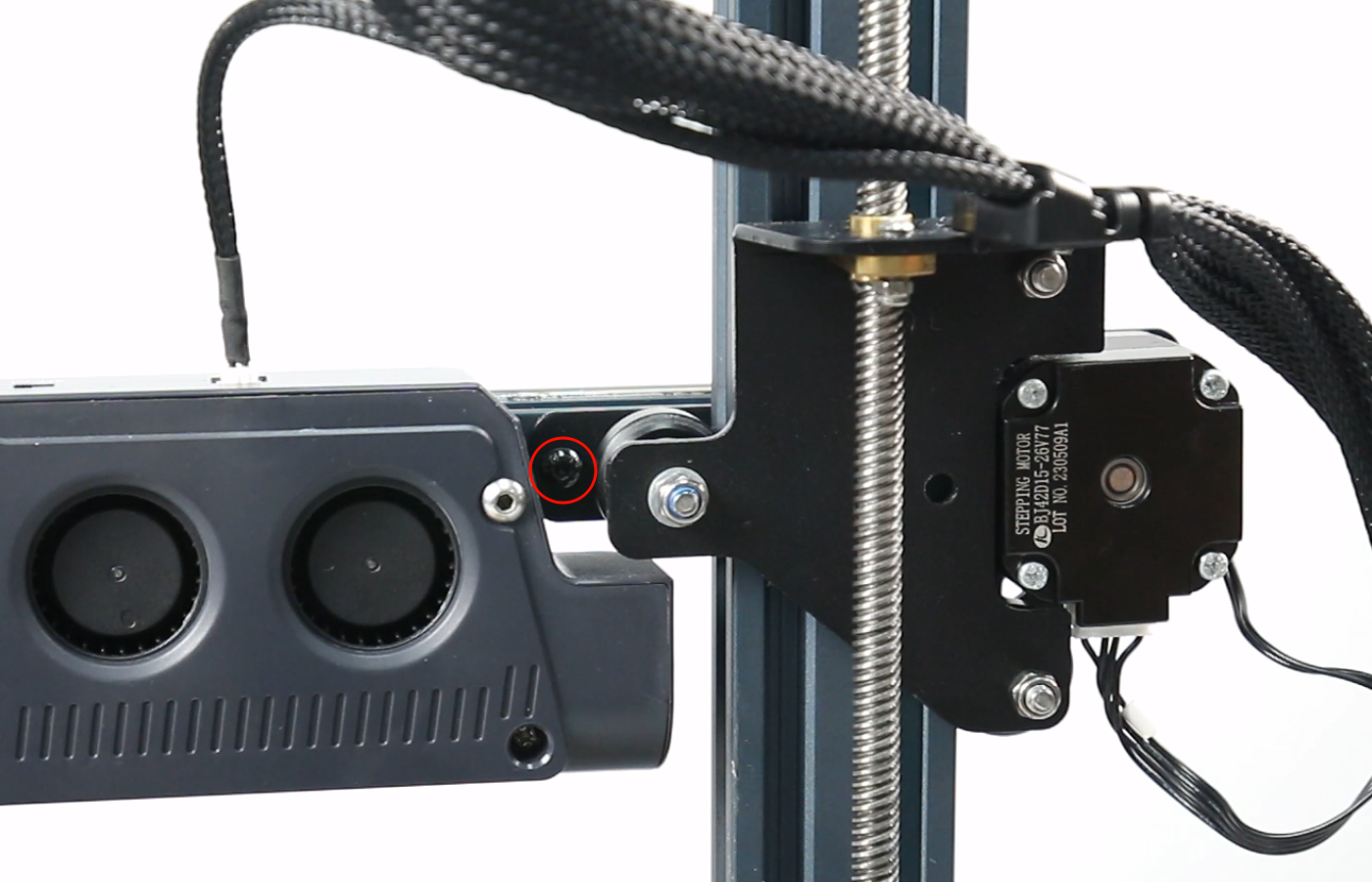

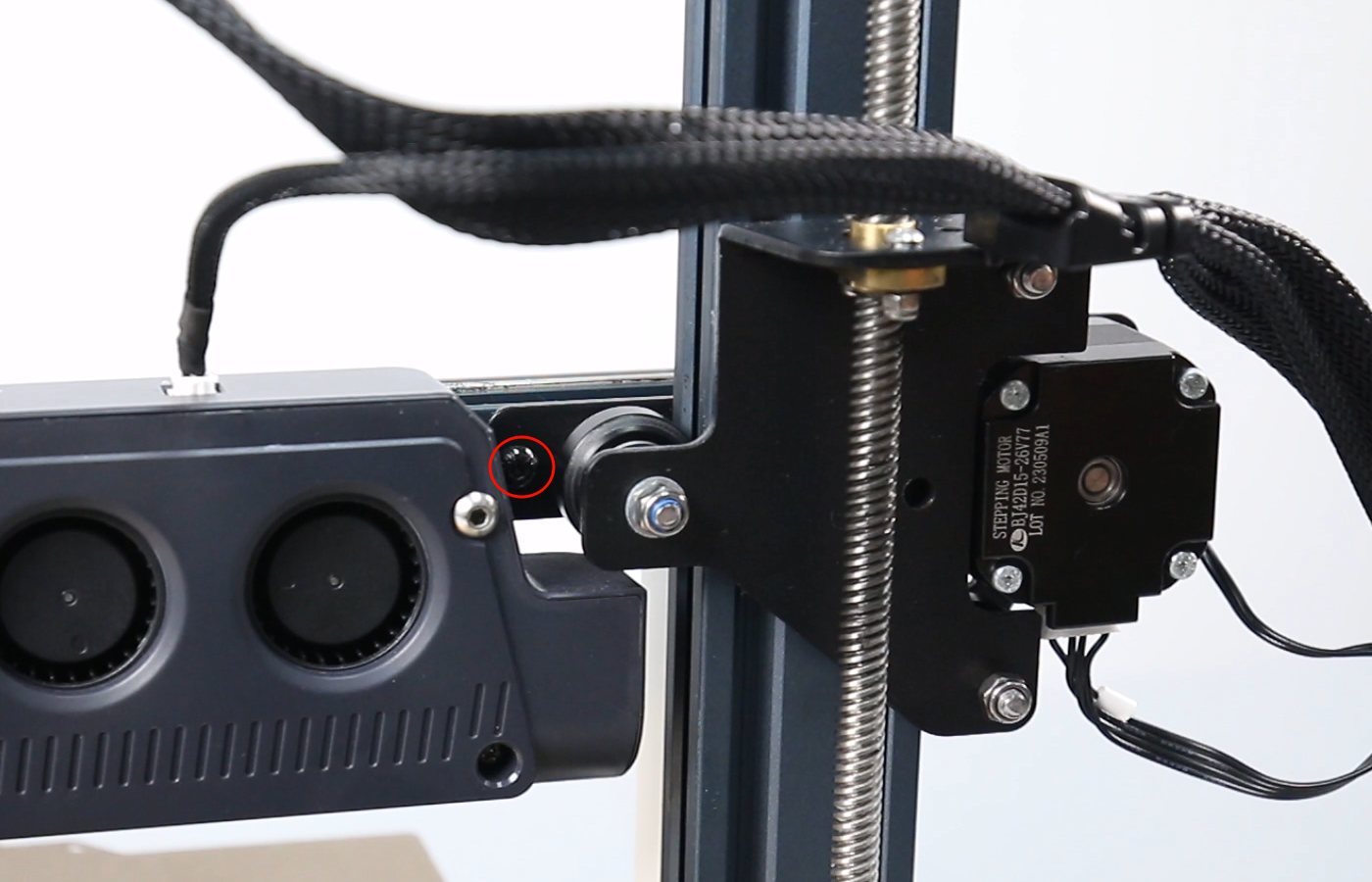

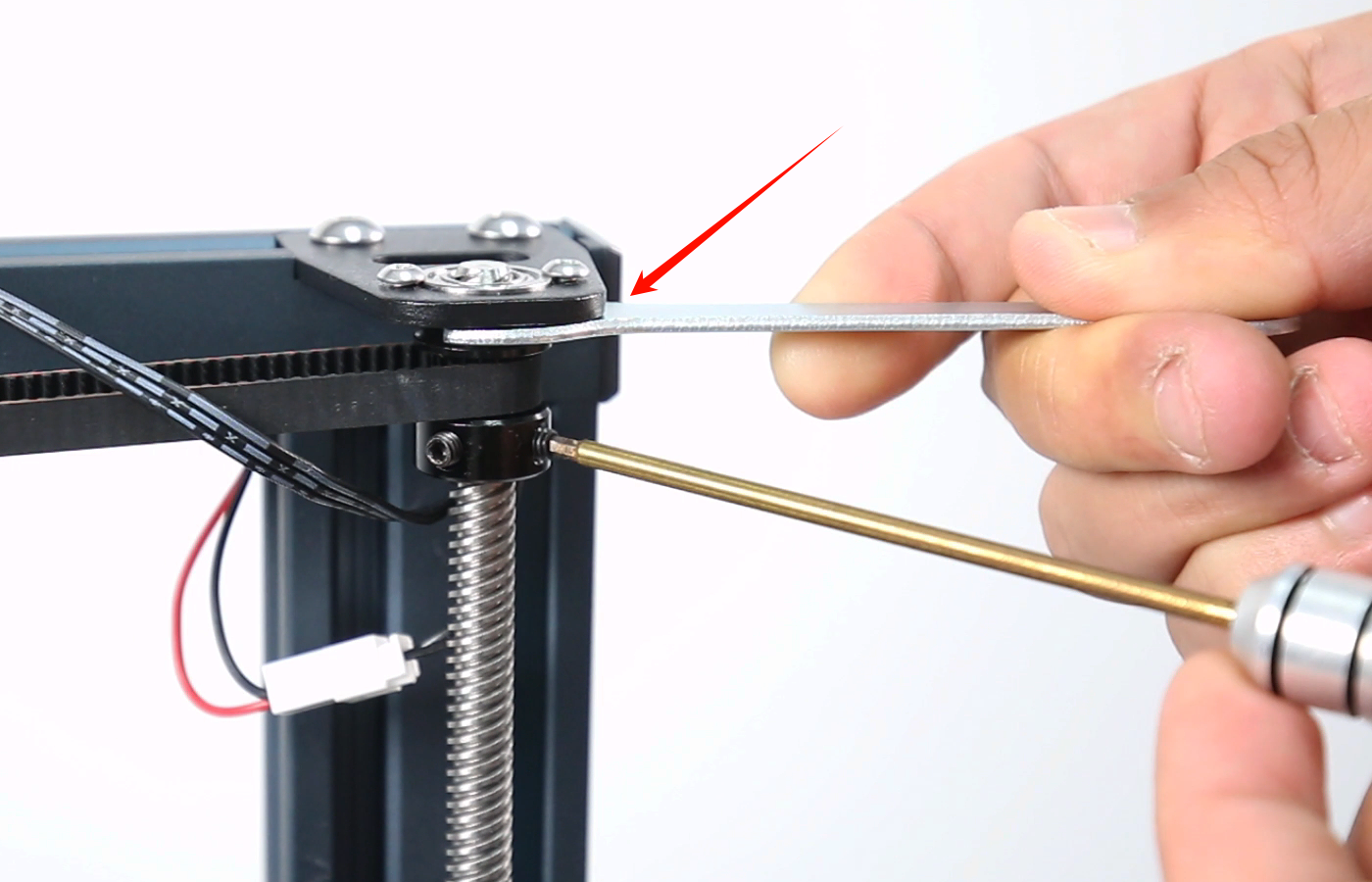

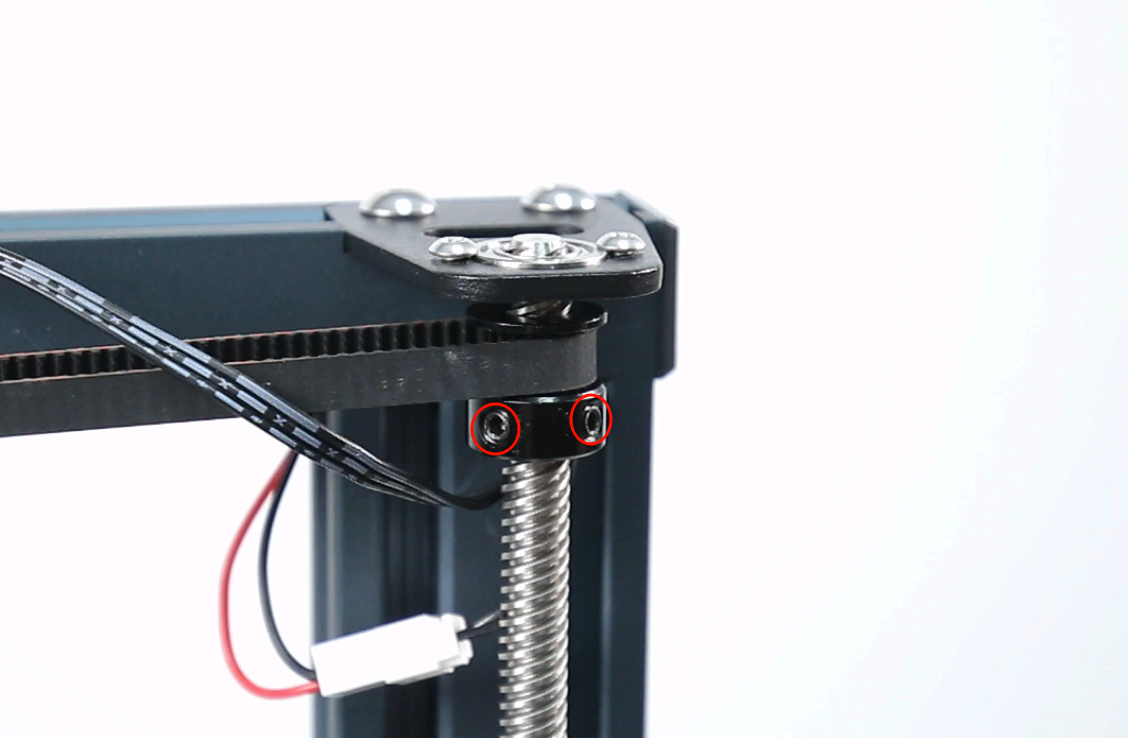

2. Use an H2.0 Allen wrench to loosen the two screws fixed on the synchronous wheels on the top of the Z-axis lead screws on both sides (loosen without removing the screws), and ensure that the synchronous wheels on the top of both sides lead screws can move freely.

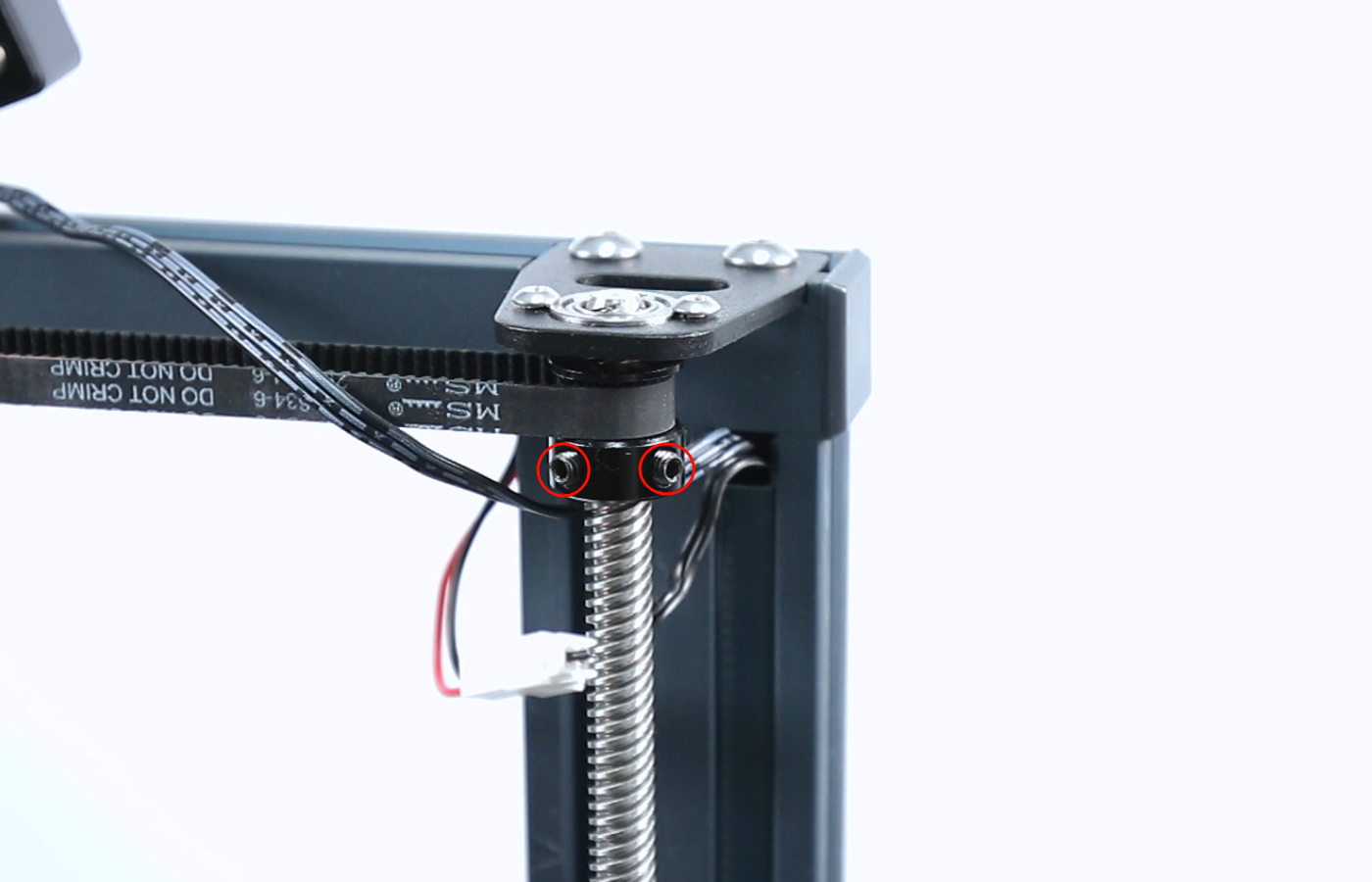

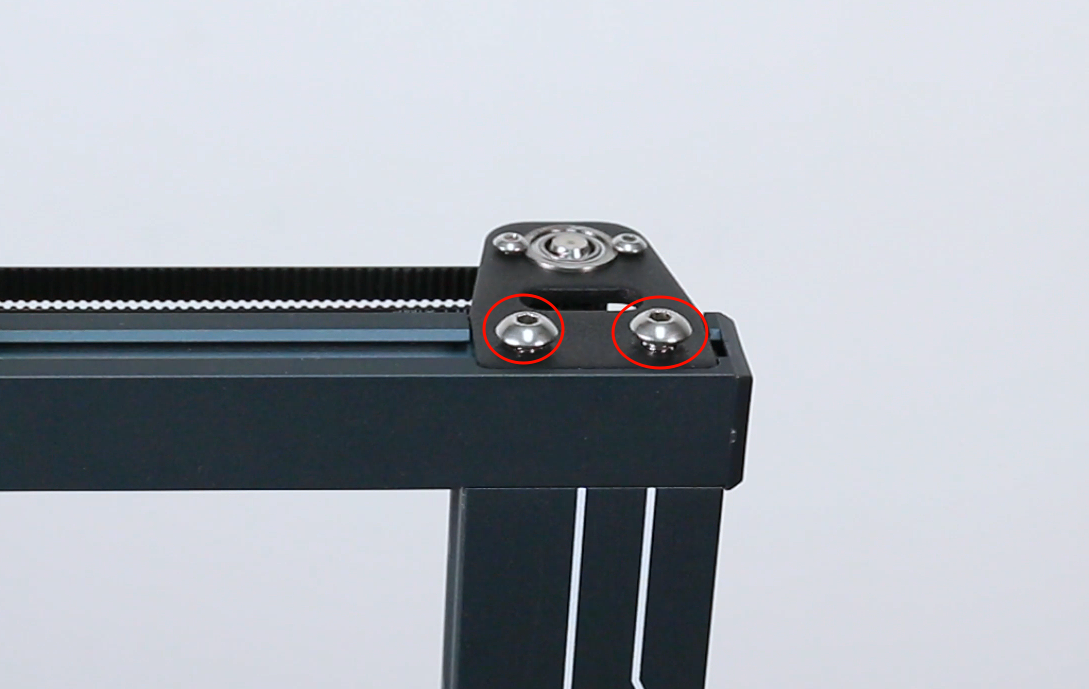

3. Use an H3.0 Allen wrench to loosen the two fixing screws on the top of the Z-axis aluminum profiles on both sides (loosen without removing the screws).

4. Place two column models of equal height under the X-axis aluminum profile (near the inside of the Z-axis aluminum profile).

5. Turn the two Z-axis couplings simultaneously by hand from the rear of the printer, and adjust the Z-axis downward until it touches the tops of the two columns placed below the X-axis.

6. Use an H2.5 Allen wrench to tighten the three screws fixed behind the X-axis aluminum profile.

7. Use an H3.0 Allen wrench to tighten the two fixing screws on the top of the Z-axis aluminum profiles on both sides.

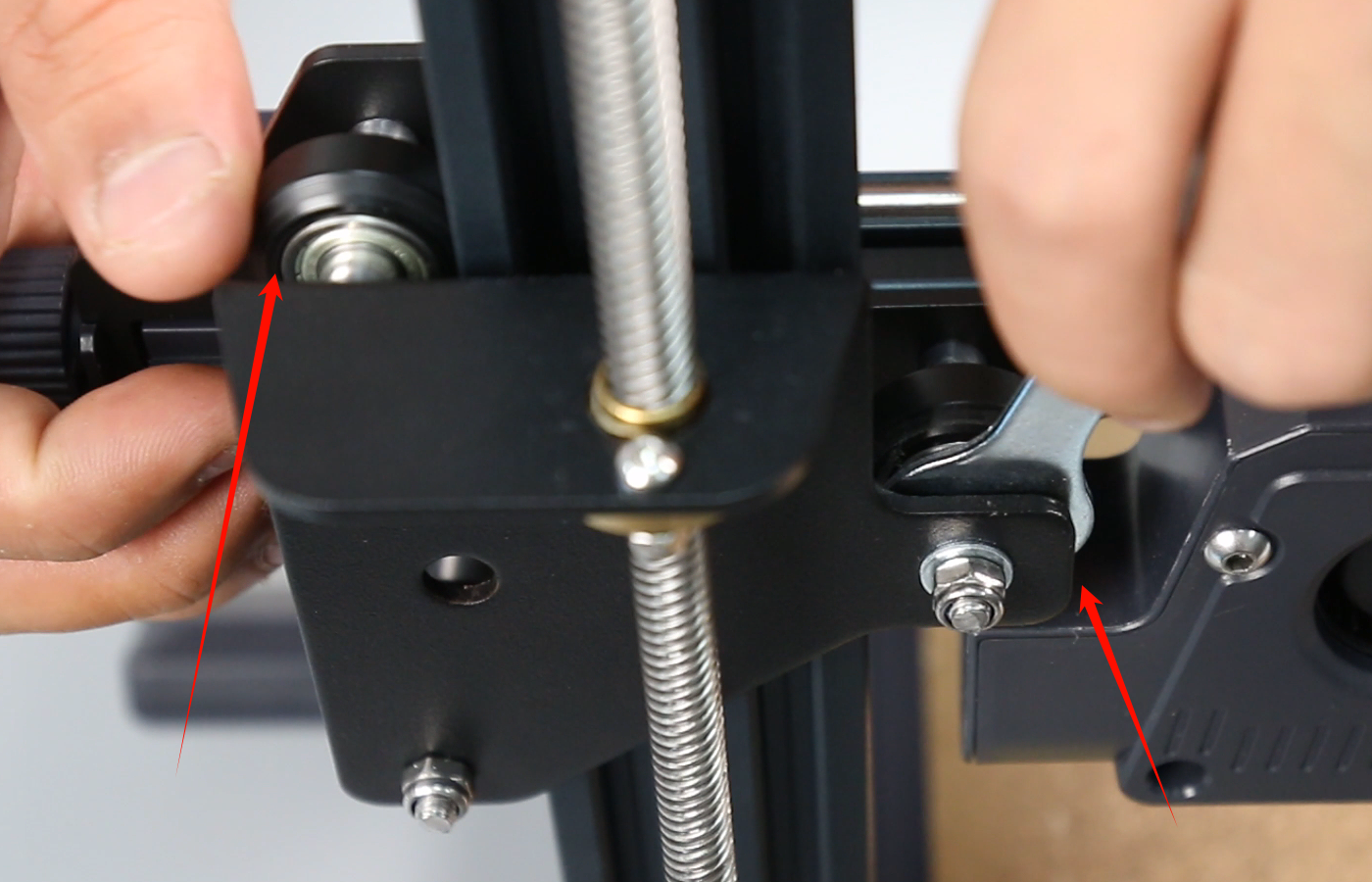

8. Use a wrench to place between the Z-axis top bearing fixing plate and the synchronous wheel.

9. Use an H2.0 Allen wrench to loosen the two screws fixed on the synchronous wheels on the top of the Z-axis lead screws on both sides (just keep the same distance between the top bearing fixing plates on both sides of the Z-axis and the synchronous wheels).

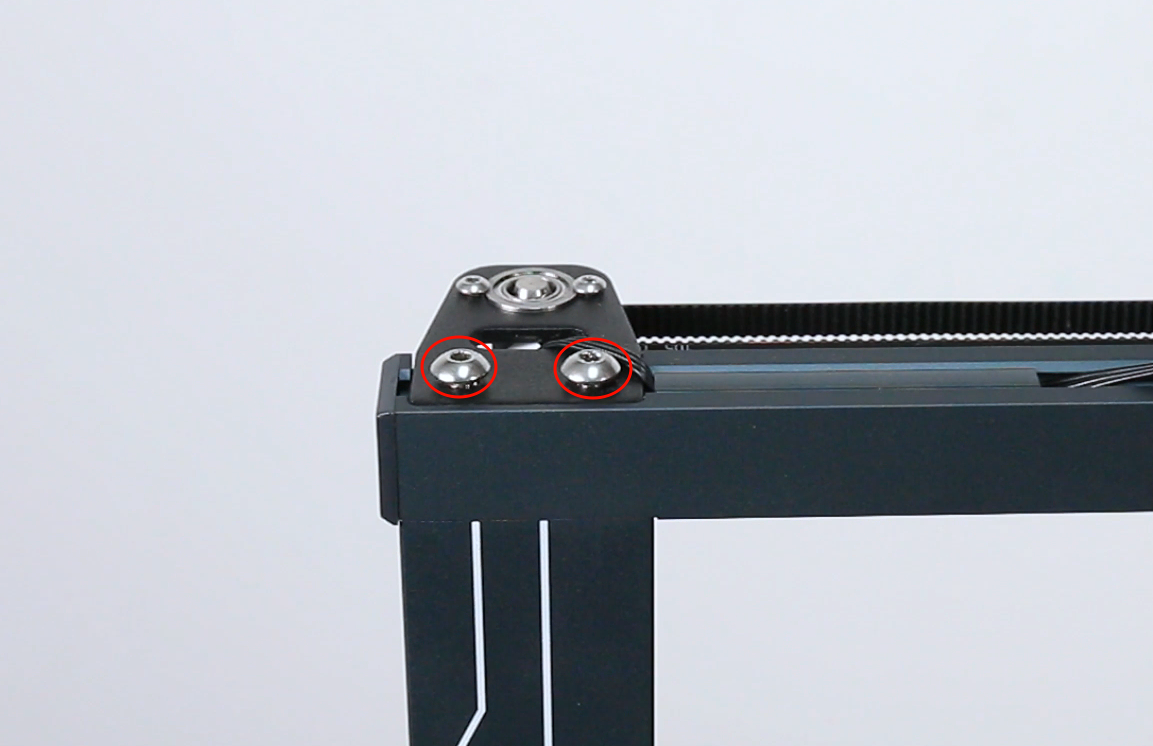

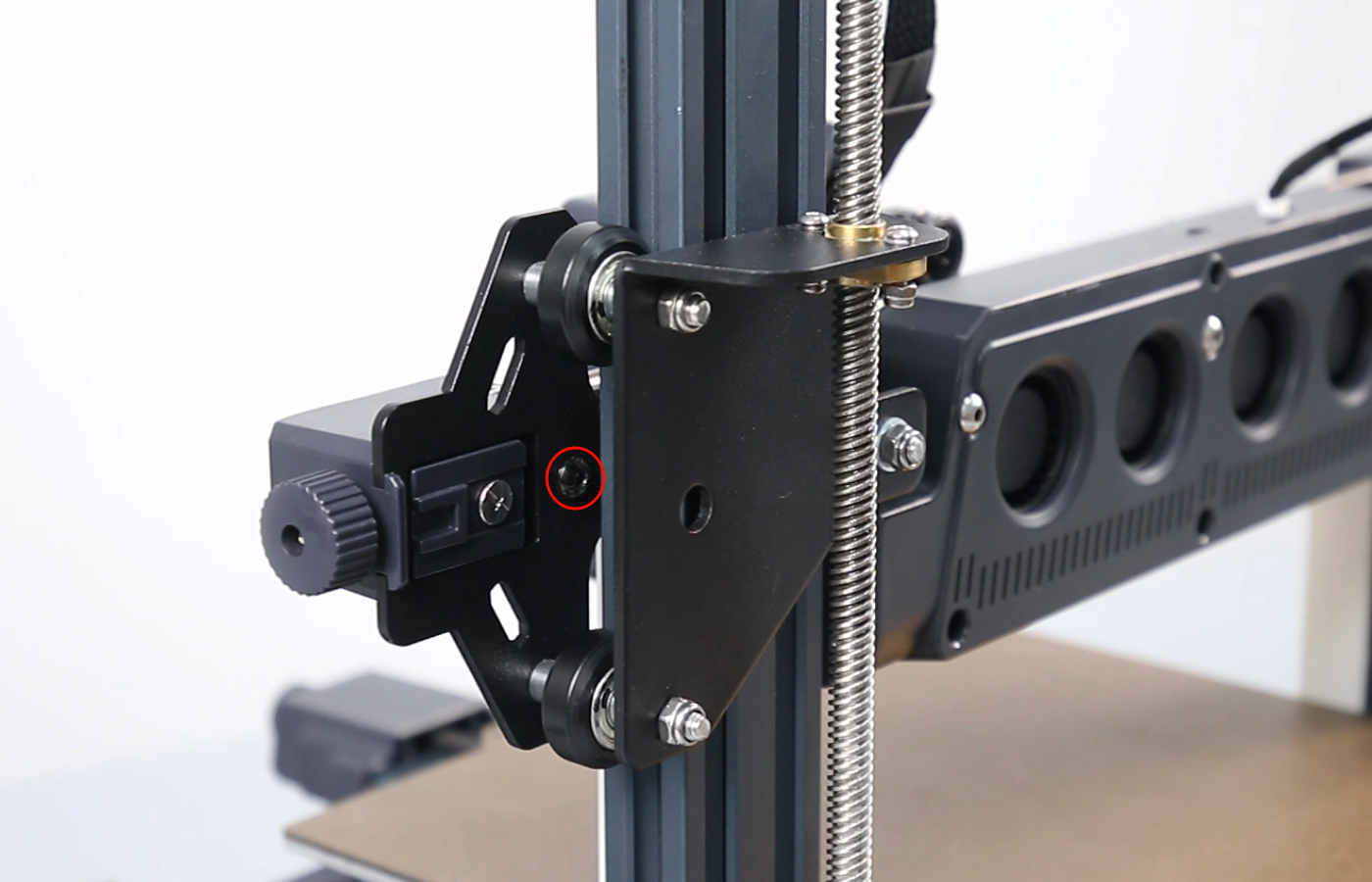

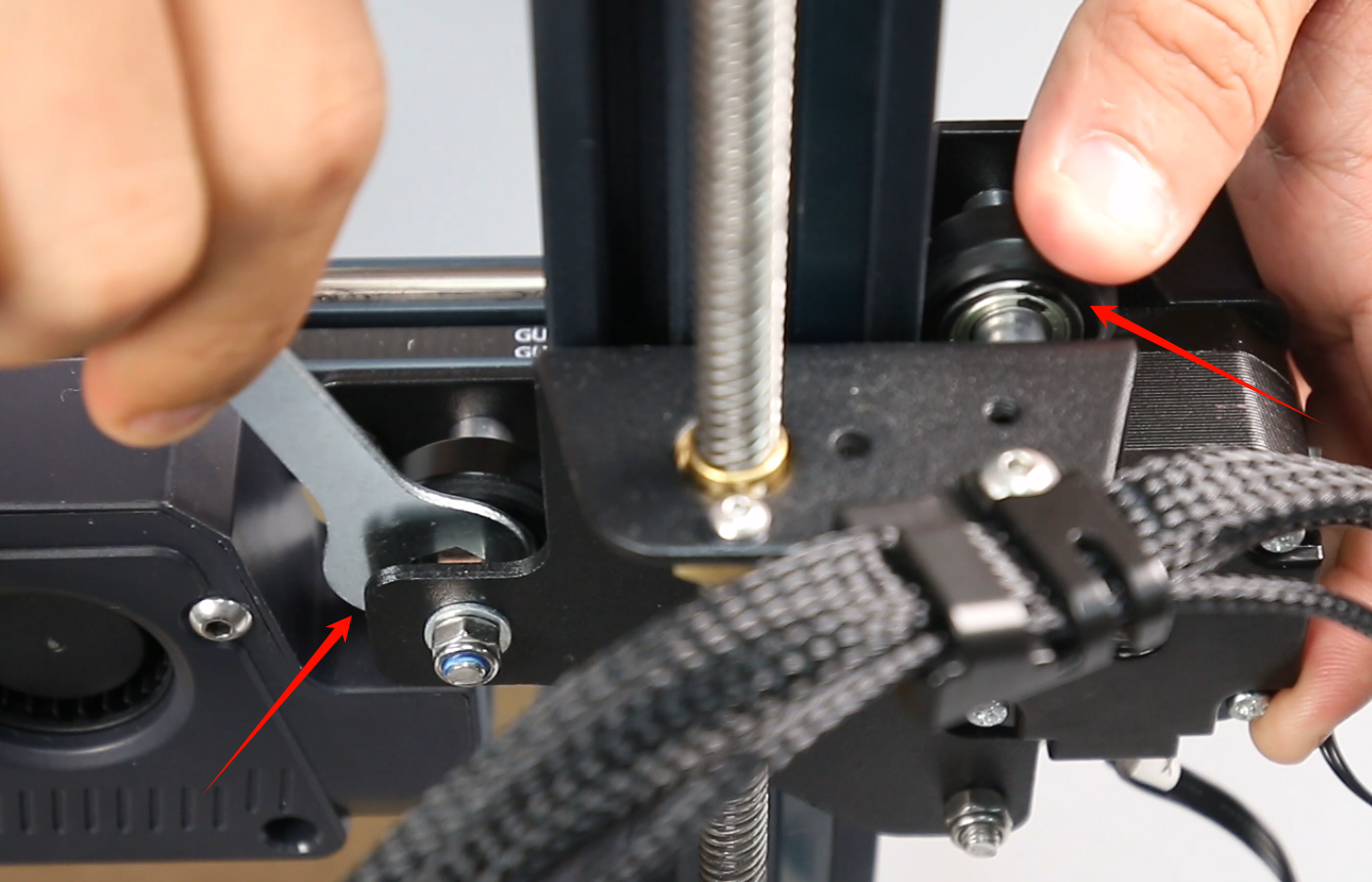

10. Use a 10mm open-end wrench to adjust the Z-axis eccentric wheel studs until the contact between the two eccentric wheels and the aluminum profile is uniform and not too tight or too loose.

11. Home the printer. After observing that the printer’s homing movement is normal, re-level the printer and it can be used normally.