Replace Teflon Tube in the Throat Pipe

Tools and materials needed

●2.5mm hex wrench

●2.0mm hex wrench

●Needle nose pliers

●PTFE tube

Reference video

Precautions before operation and machine status

Some of the operations involving high-temperature print heads are dangerous. Please take all necessary precautions when performing these operations, wearing insulated gloves is recommended. For some operations, please turn off the machine and wait for the print head to cool down completely.

Operation steps

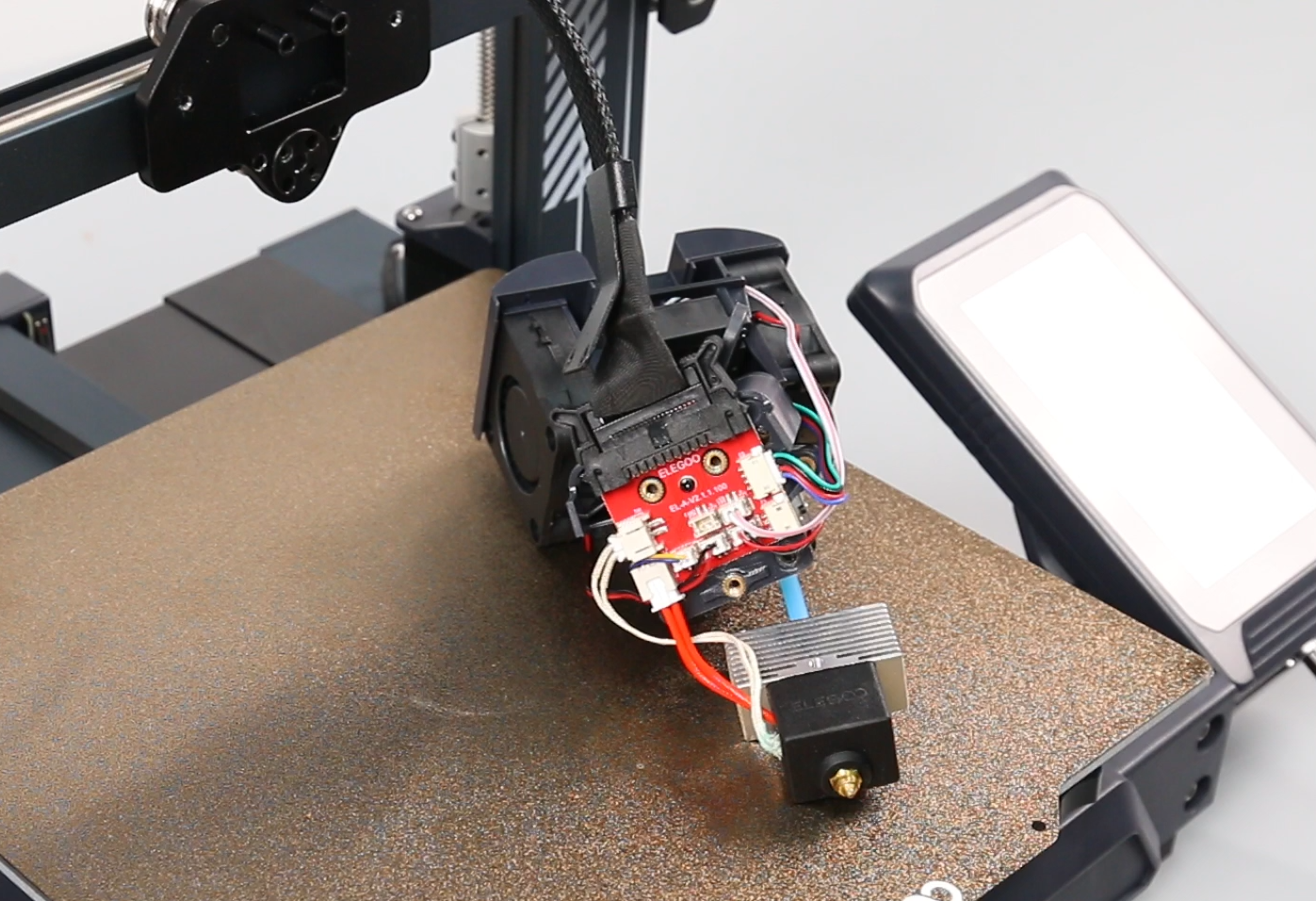

1-Remove the print head

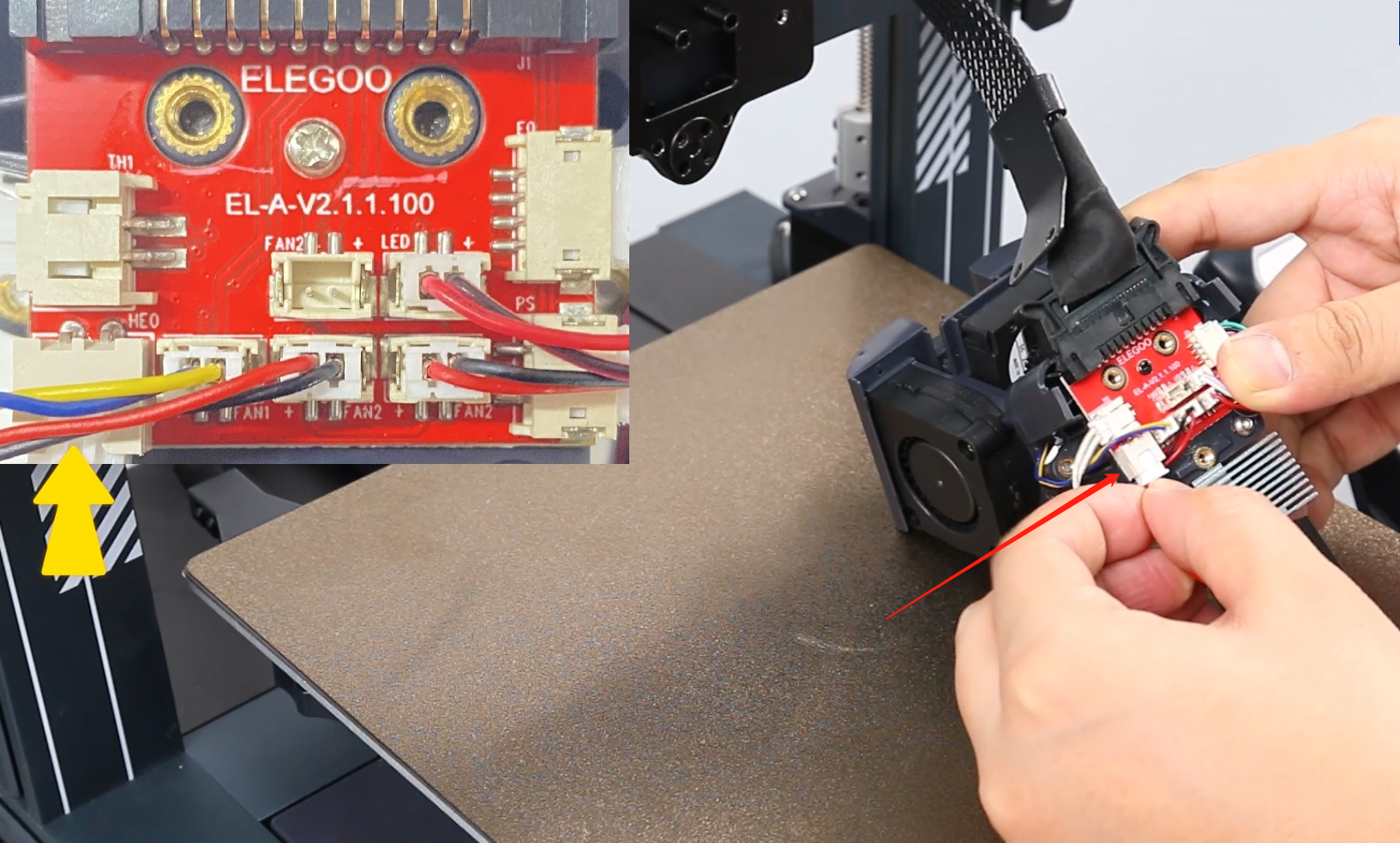

- Power off the printer, unplug the port cable of the fan assembly located directly behind the print head, use a 2.5mm hex wrench to loosen the three fixing screws of the "rear fan assembly", and remove the rear fan assembly.

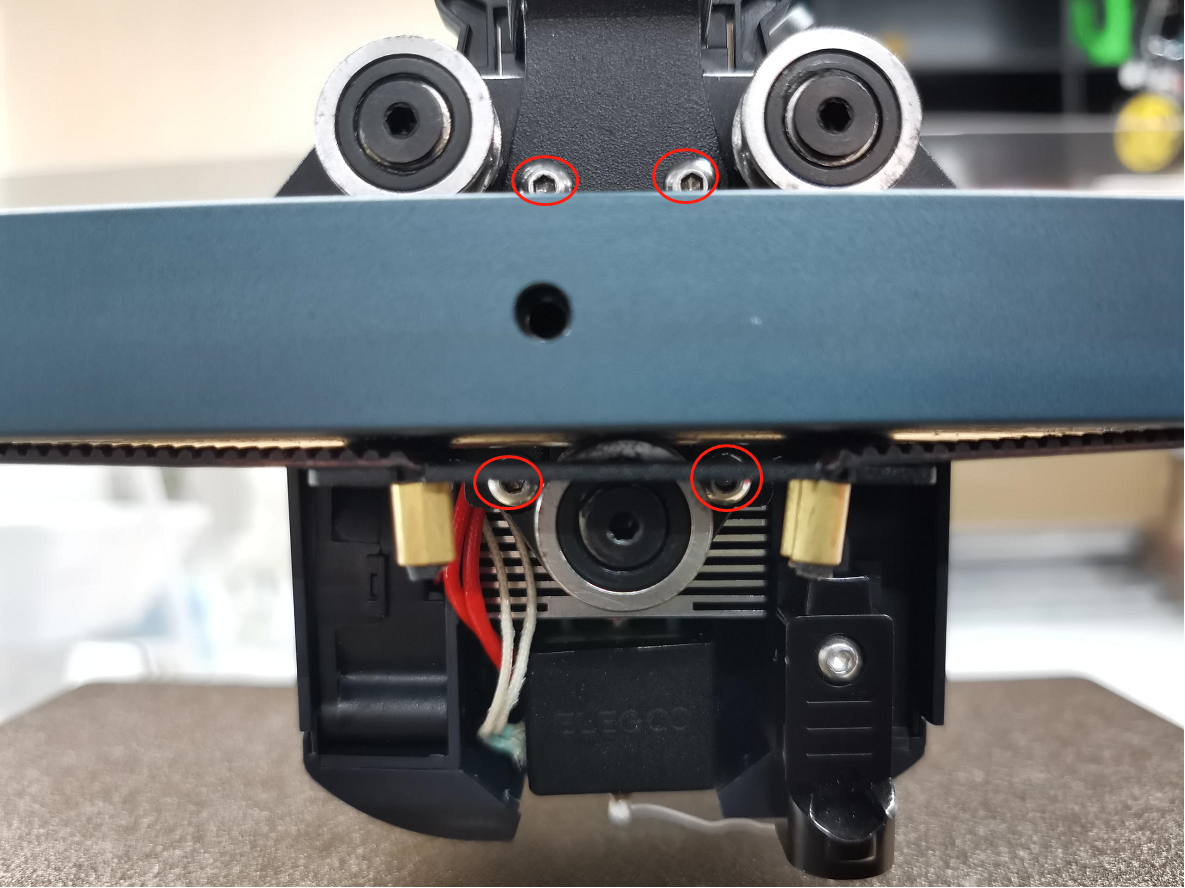

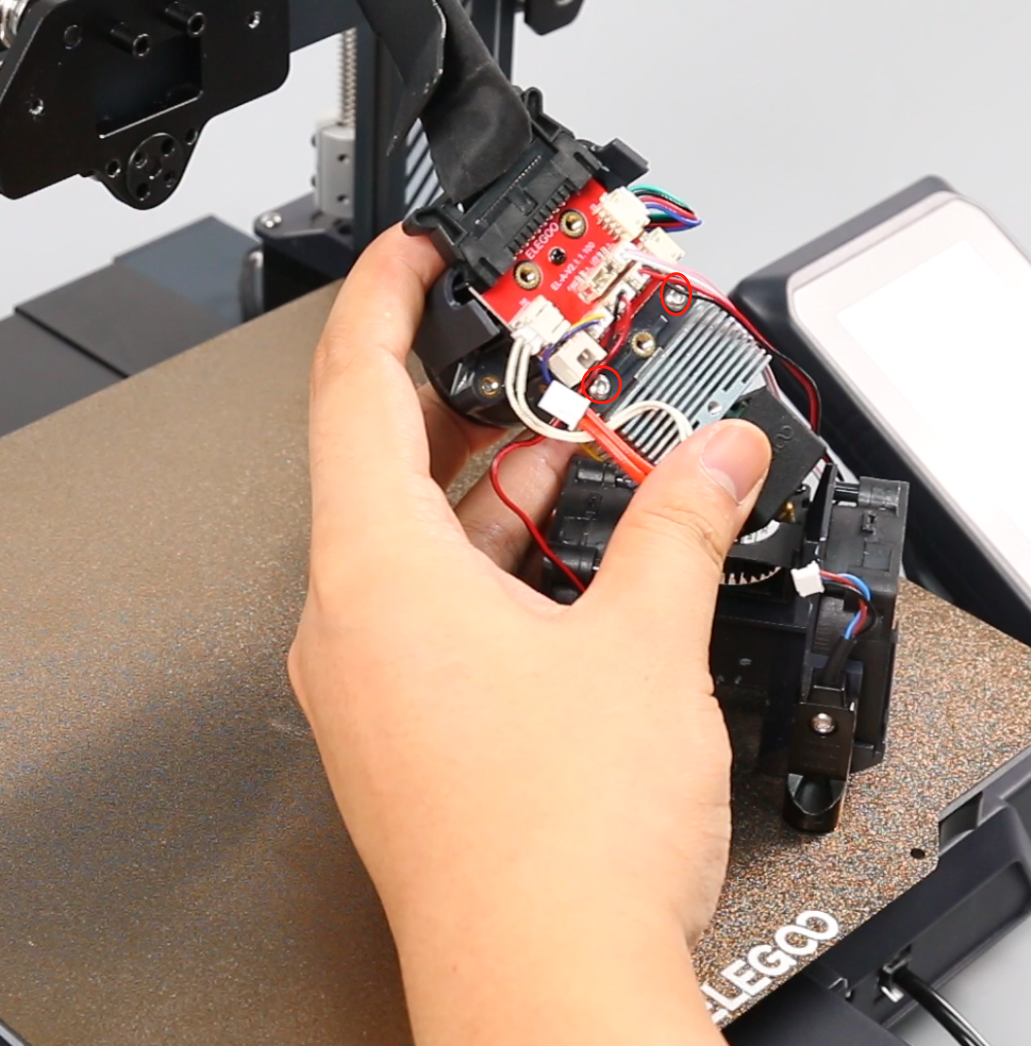

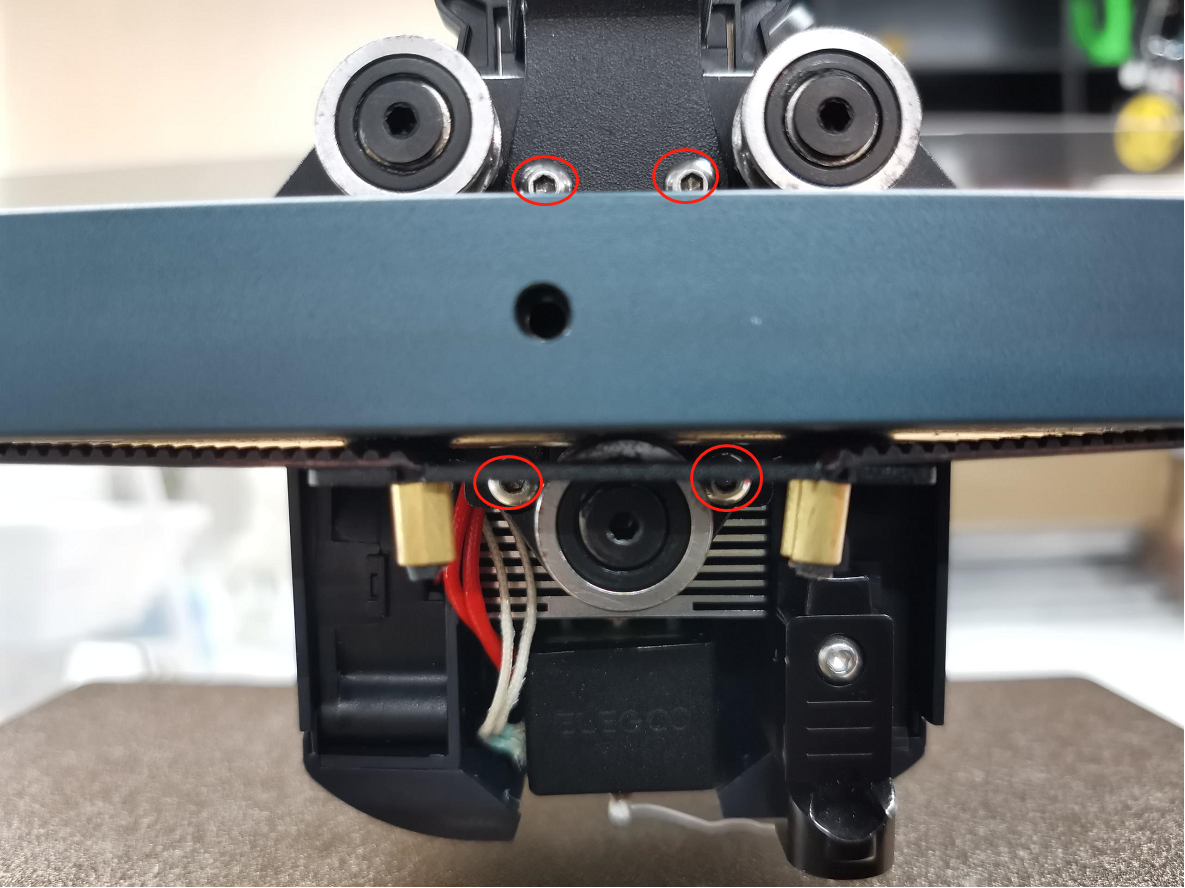

2. Use a 2.0mm hex wrench to loosen the two fixing screws of the "cable fastener" and the two fixing screws of the whole print head assembly.

3. Use a 2.0mm hex wrench to loosen the two fixing screws of the "print head front cover" and remove the whole print head assembly.

2-Replace the PTFE tube in the throat pipe

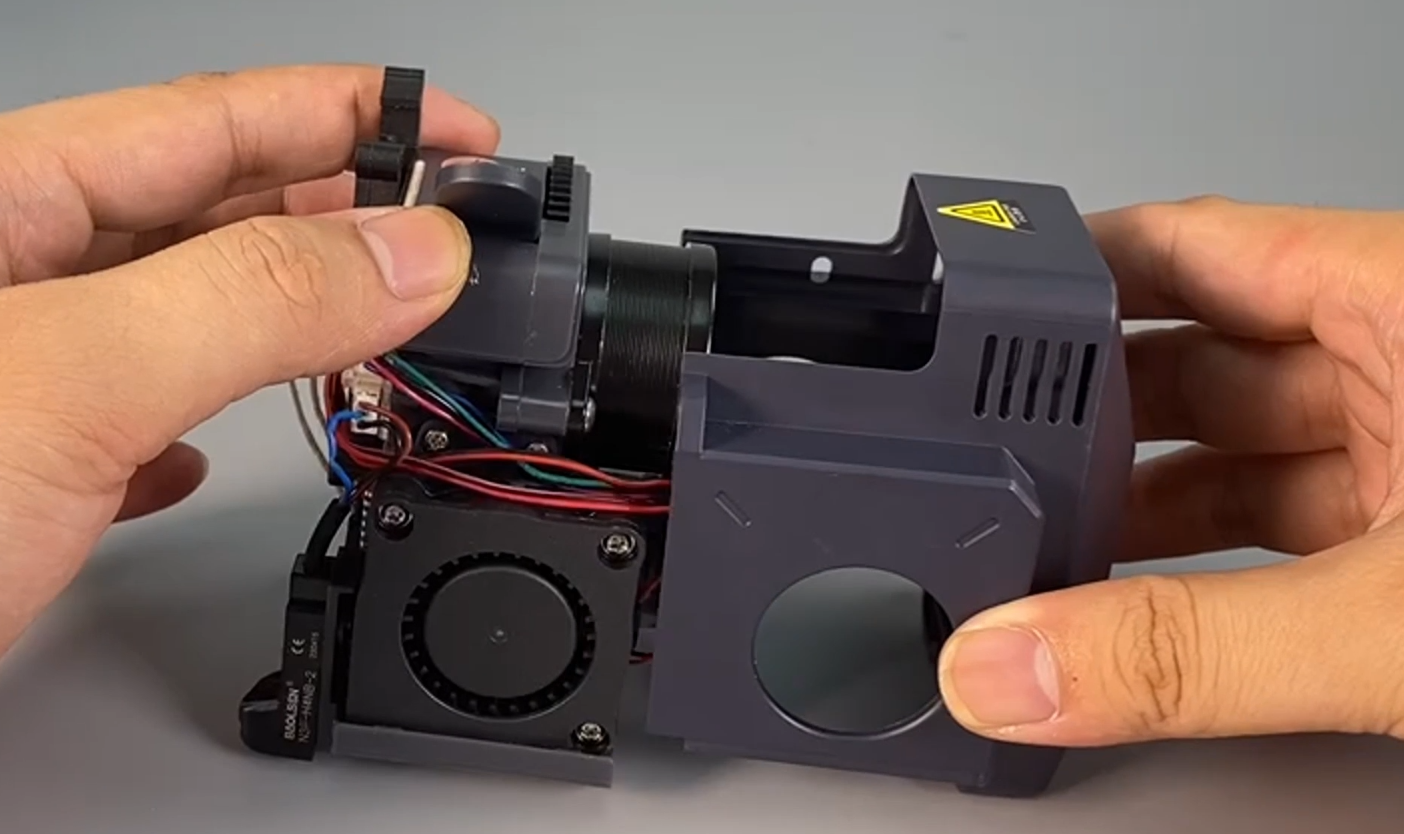

- Separate the front cover of the whole print head assembly, and use a Phillips screwdriver to loosen the four fixing screws of the "fan bracket" (two on each side).

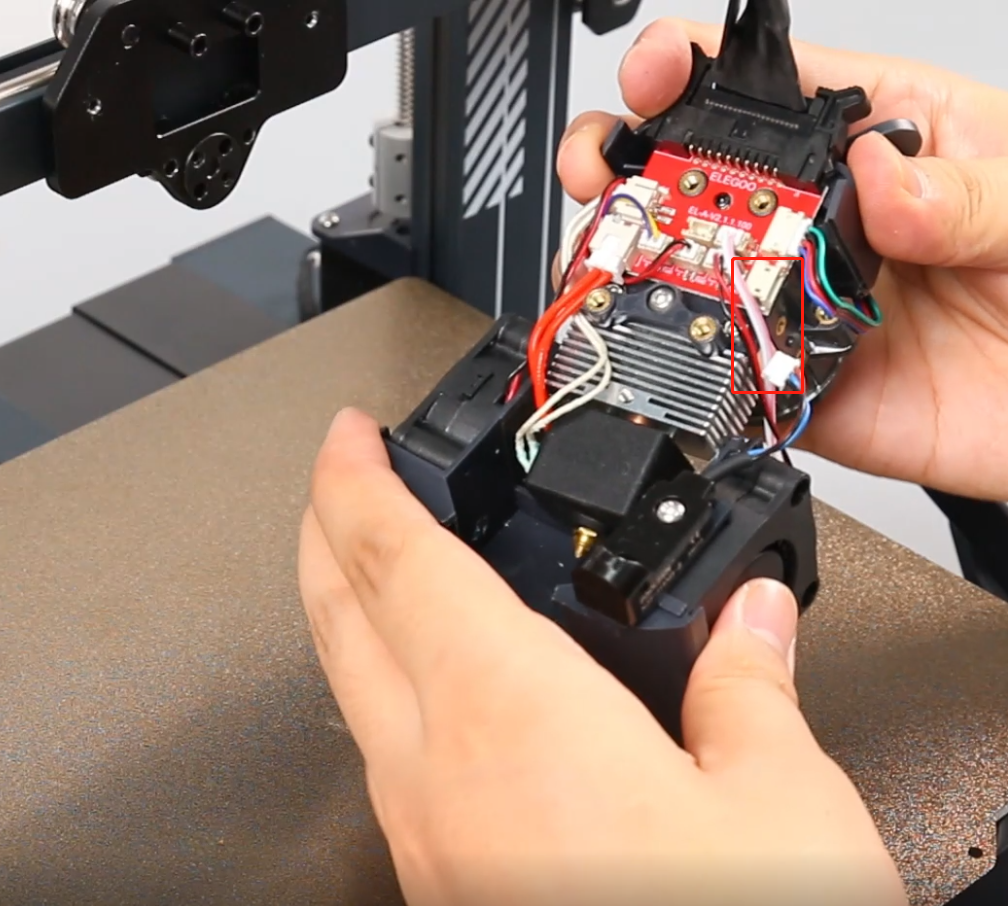

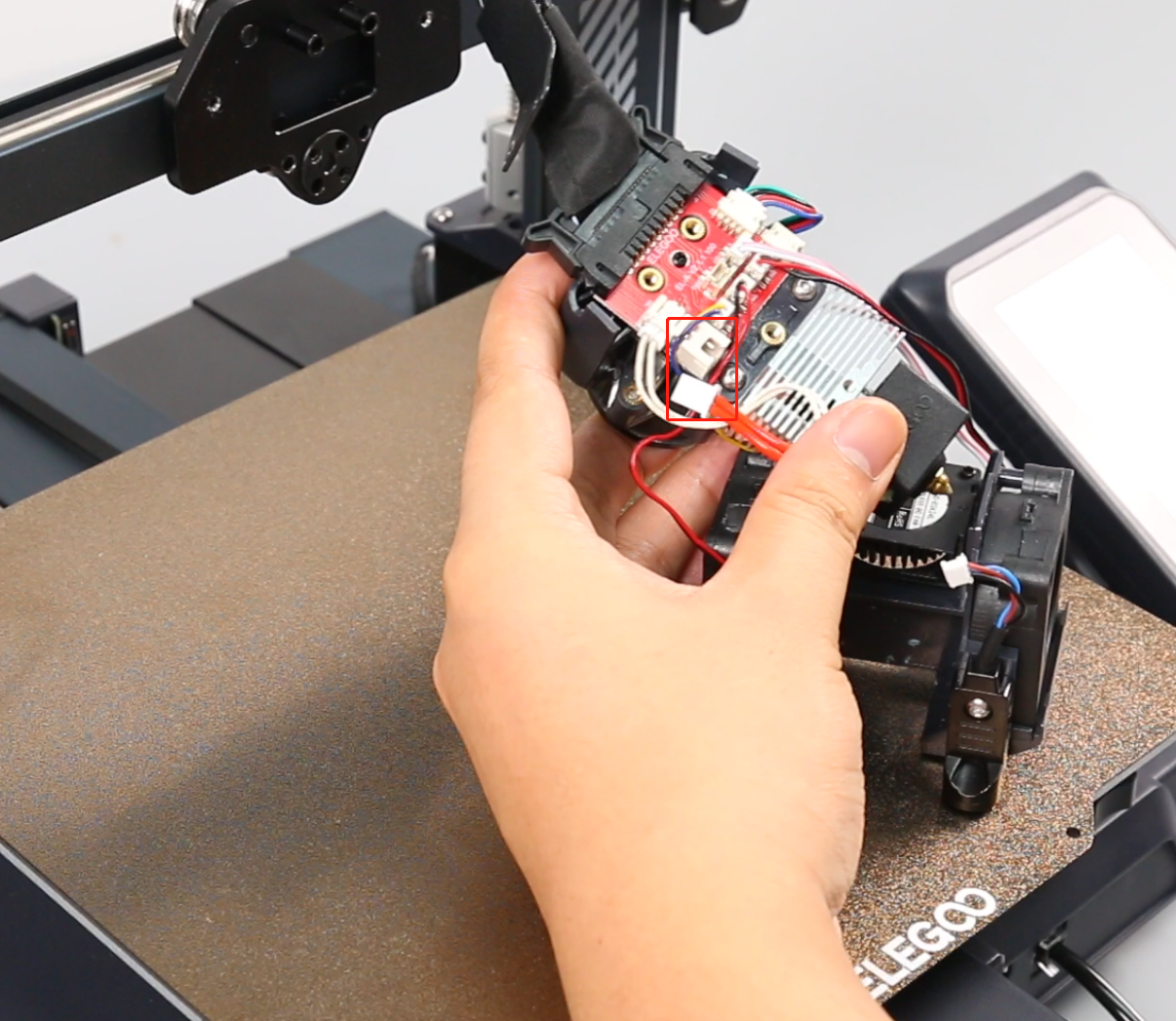

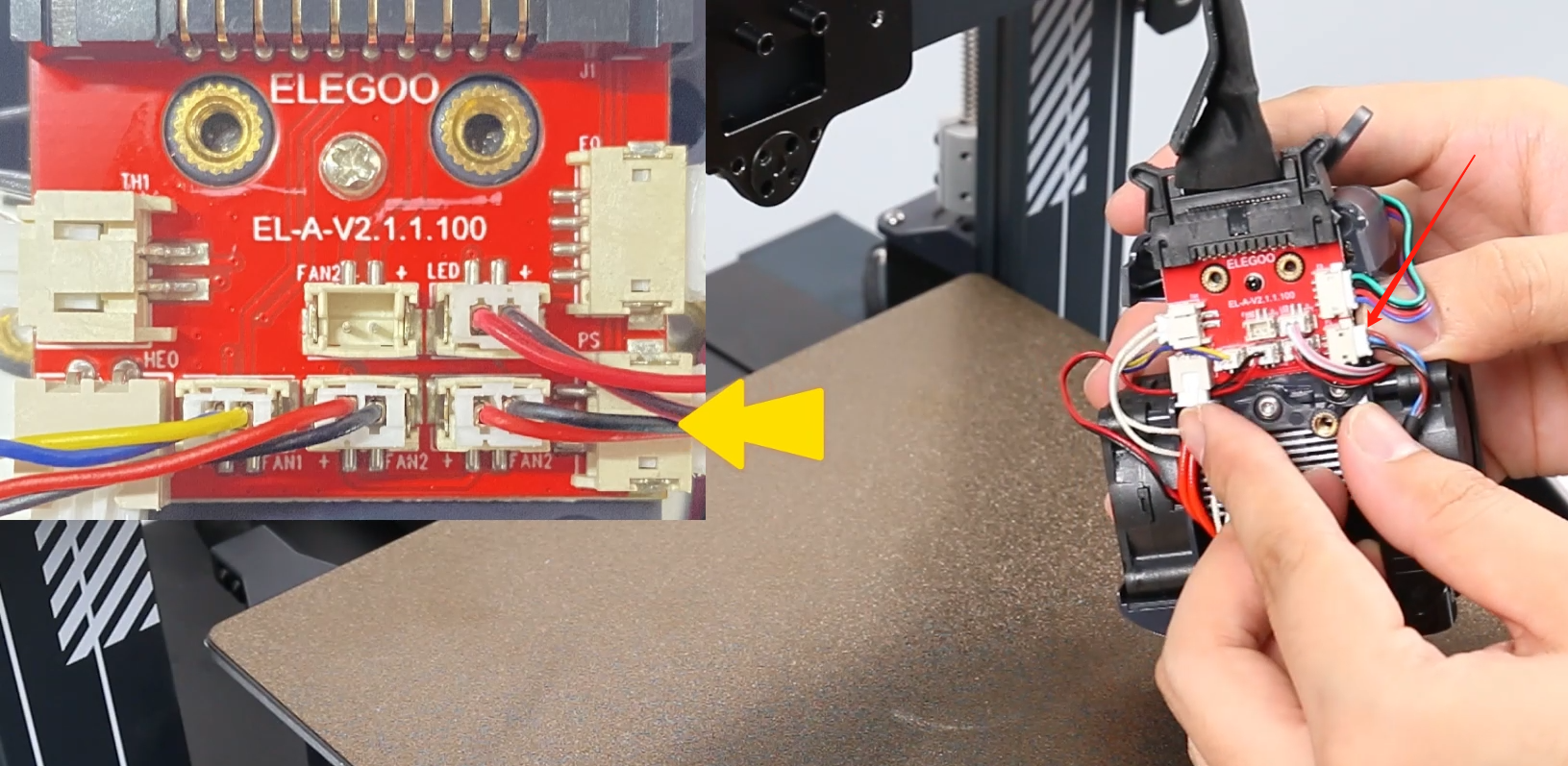

- Unplug the cable port of the "proximity switch" in the extrusion adapter board, remove the "fan bracket" assembly downwards, and place it behind the nozzle.

- Use a 2.0mm hex wrench to loosen one screw of the "connector", remove the connector, and unplug the cable port of the "heater" in the extrusion adapter board.

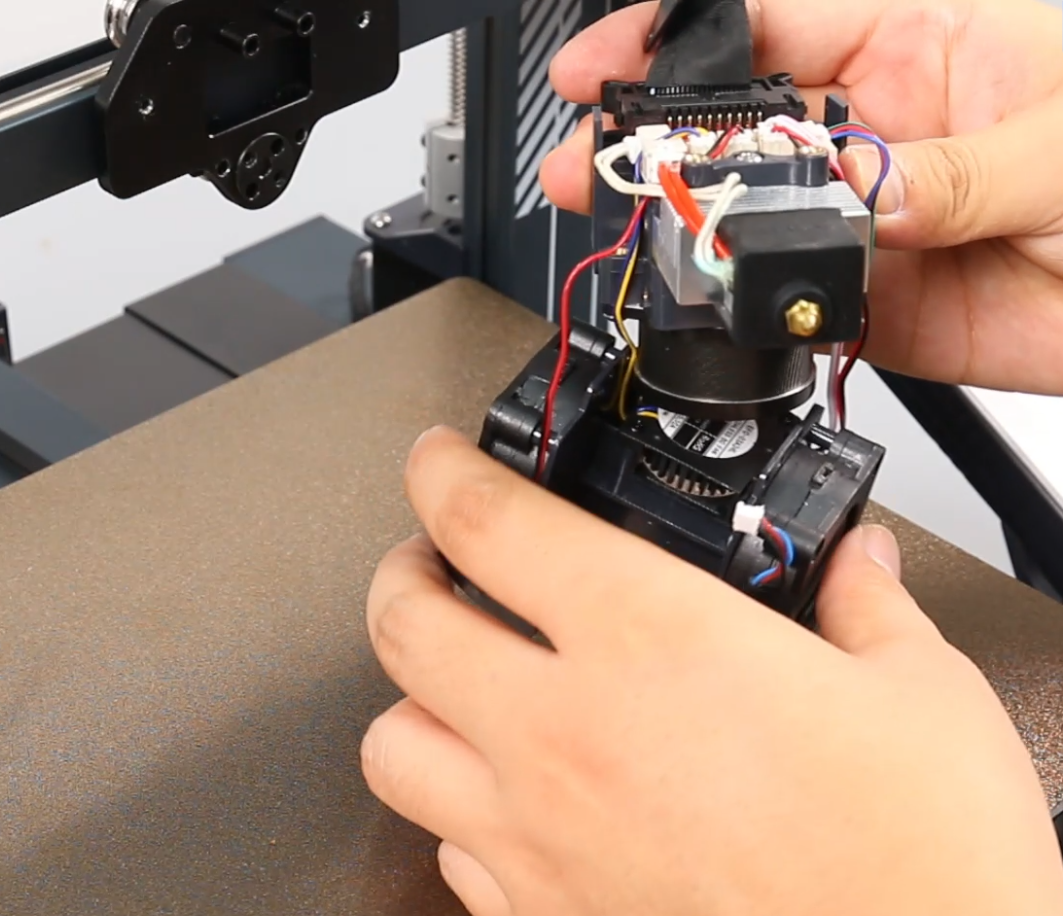

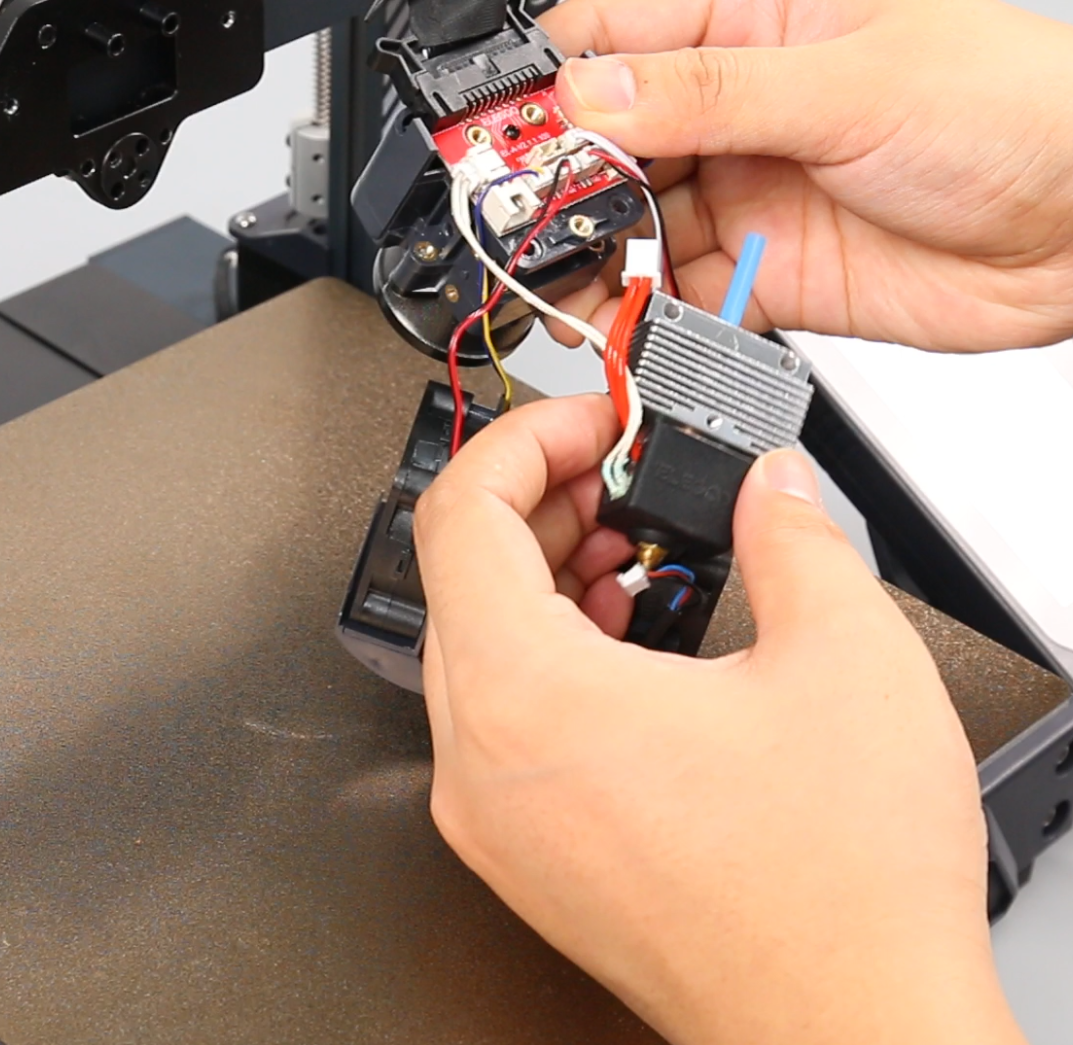

- Use a 2.0mm hex wrench to loosen the two fixing screws of the "nozzle assembly" and remove the "nozzle assembly" downwards.

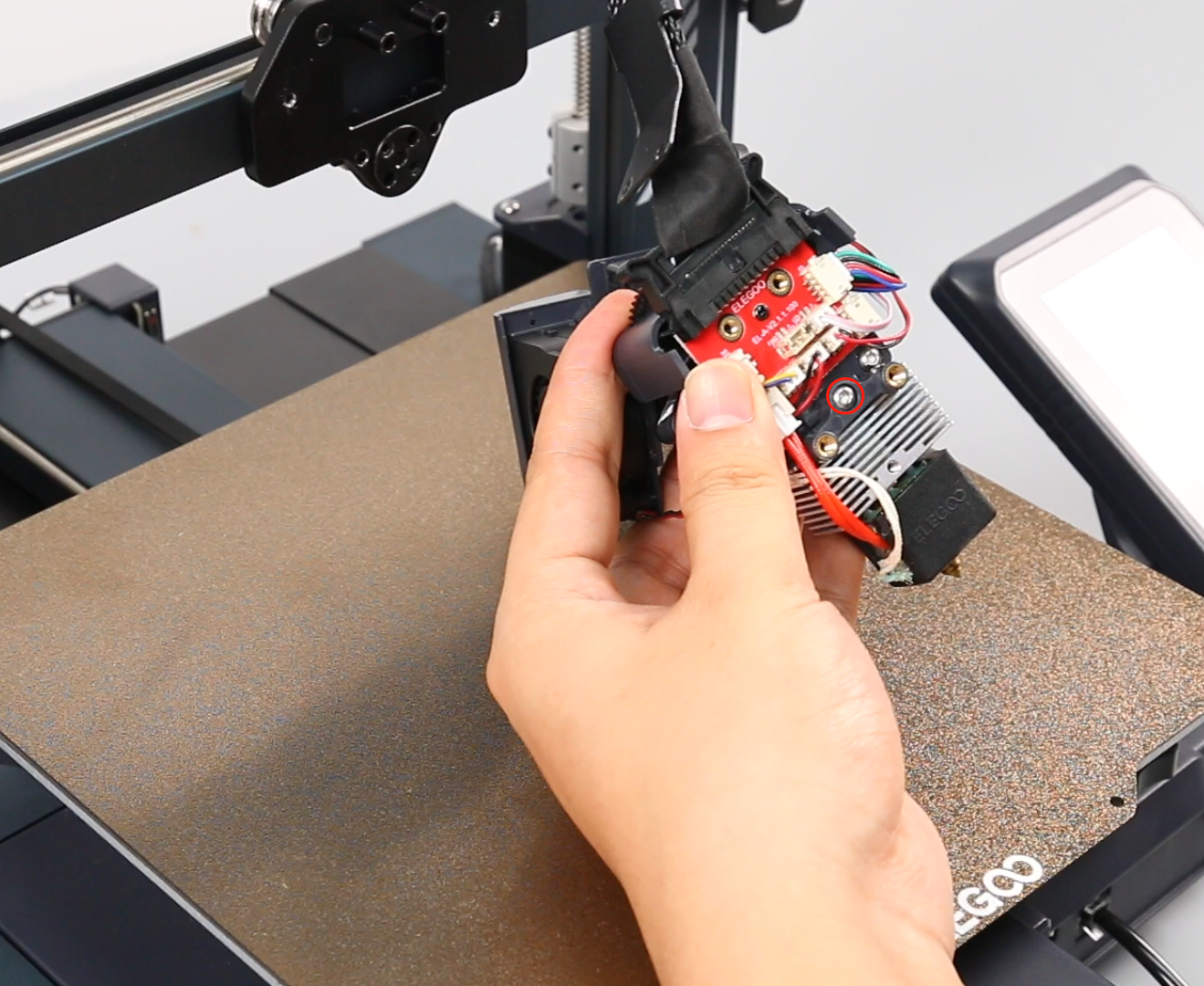

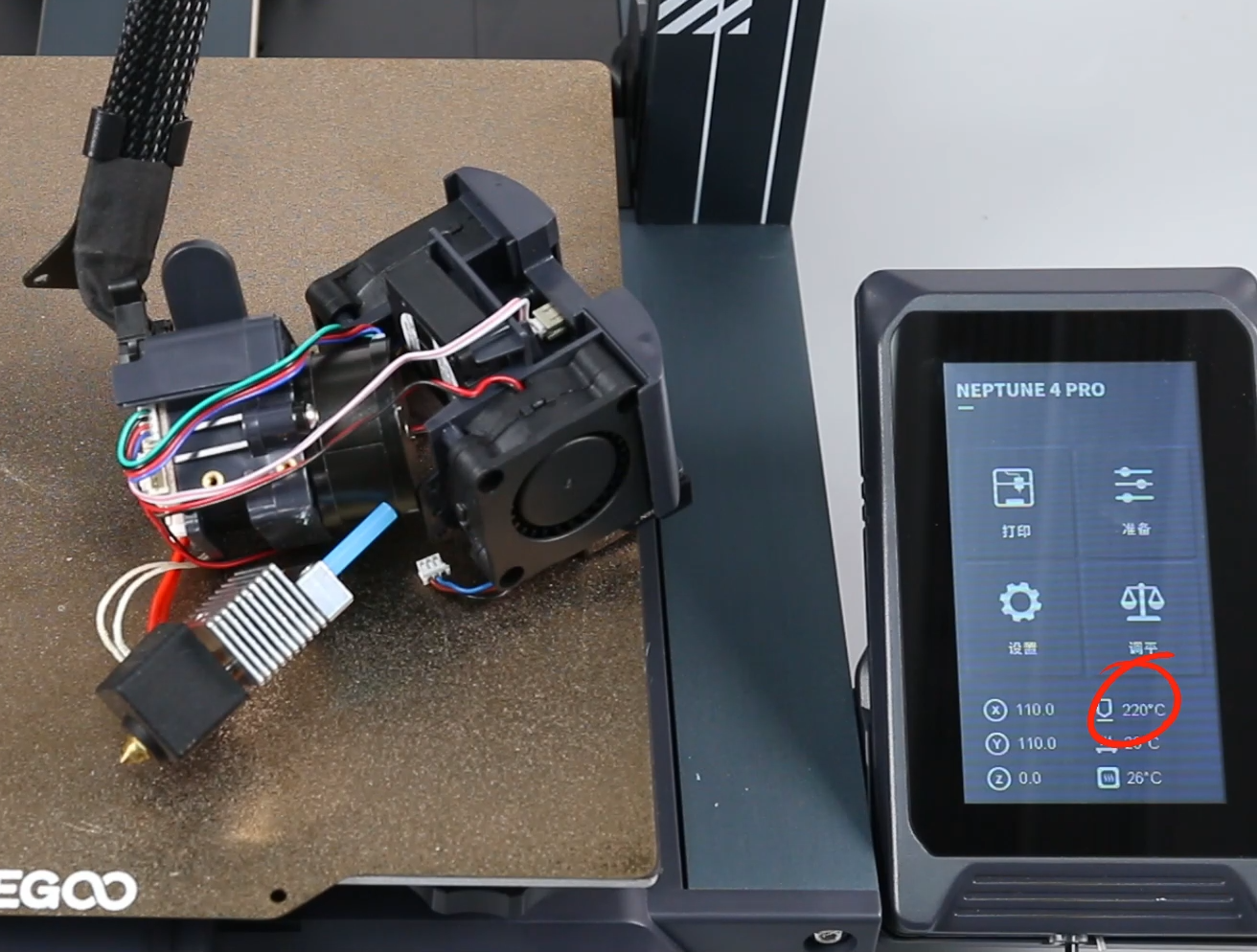

- Insert the cable port of the heater into the "HE0" port of the extrusion adapter board, and place the whole print head flat on the surface of the printing platform (The nozzle needs to be heated to avoid direct contact with the printing platform).

- Power on the printer, click [Prepare - Temperature] on the touch screen, and then heat the nozzle temperature to 220°C in the temperature control interface.

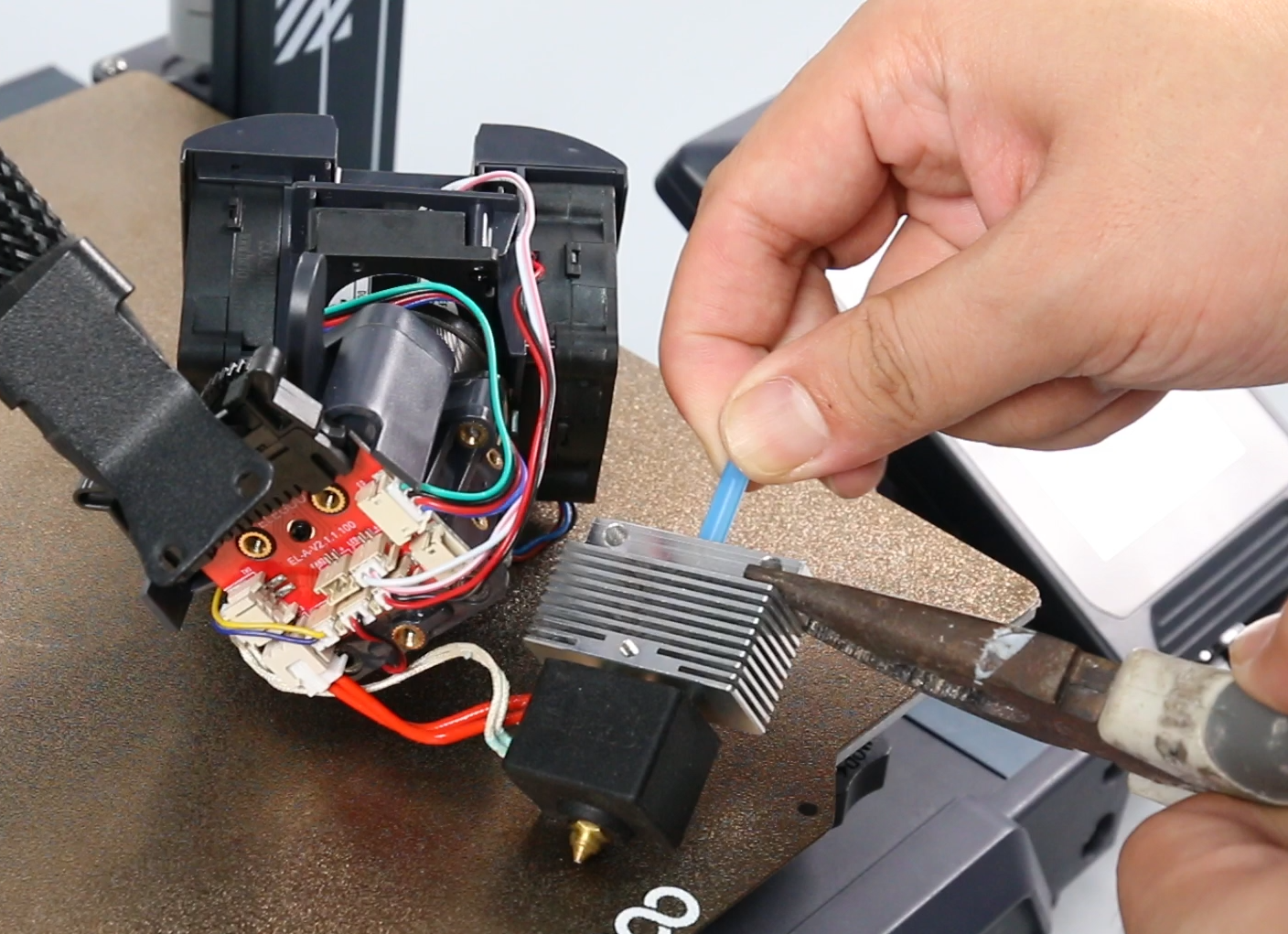

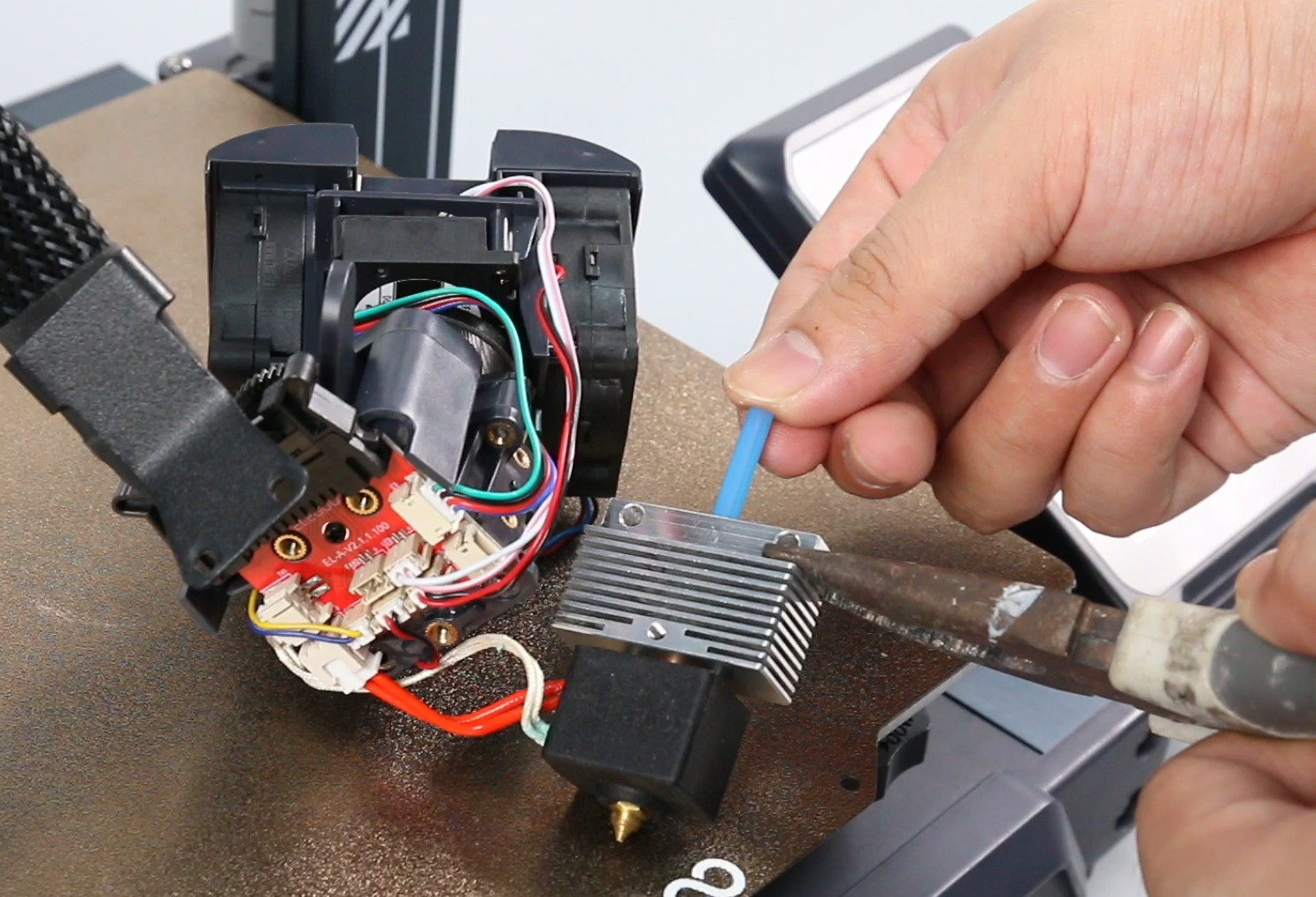

- When the nozzle is at high temperatures, use pliers to hold the heat sink of the print head assembly, and then pull out the Teflon tube inside the throat pipe. (Note the high temperature, do not touch the nozzle and heated chamber).

- Take out the new "Teflon tube" and insert it into the throat pipe (Press down to ensure it reaches the bottom of the throat).

- Power off the printer, unplug the cable port of the "heater" in the extrusion adapter board, then place the "nozzle assembly" in the mounting position, and use a 2.0mm hex wrench to tighten the two fixing screws.

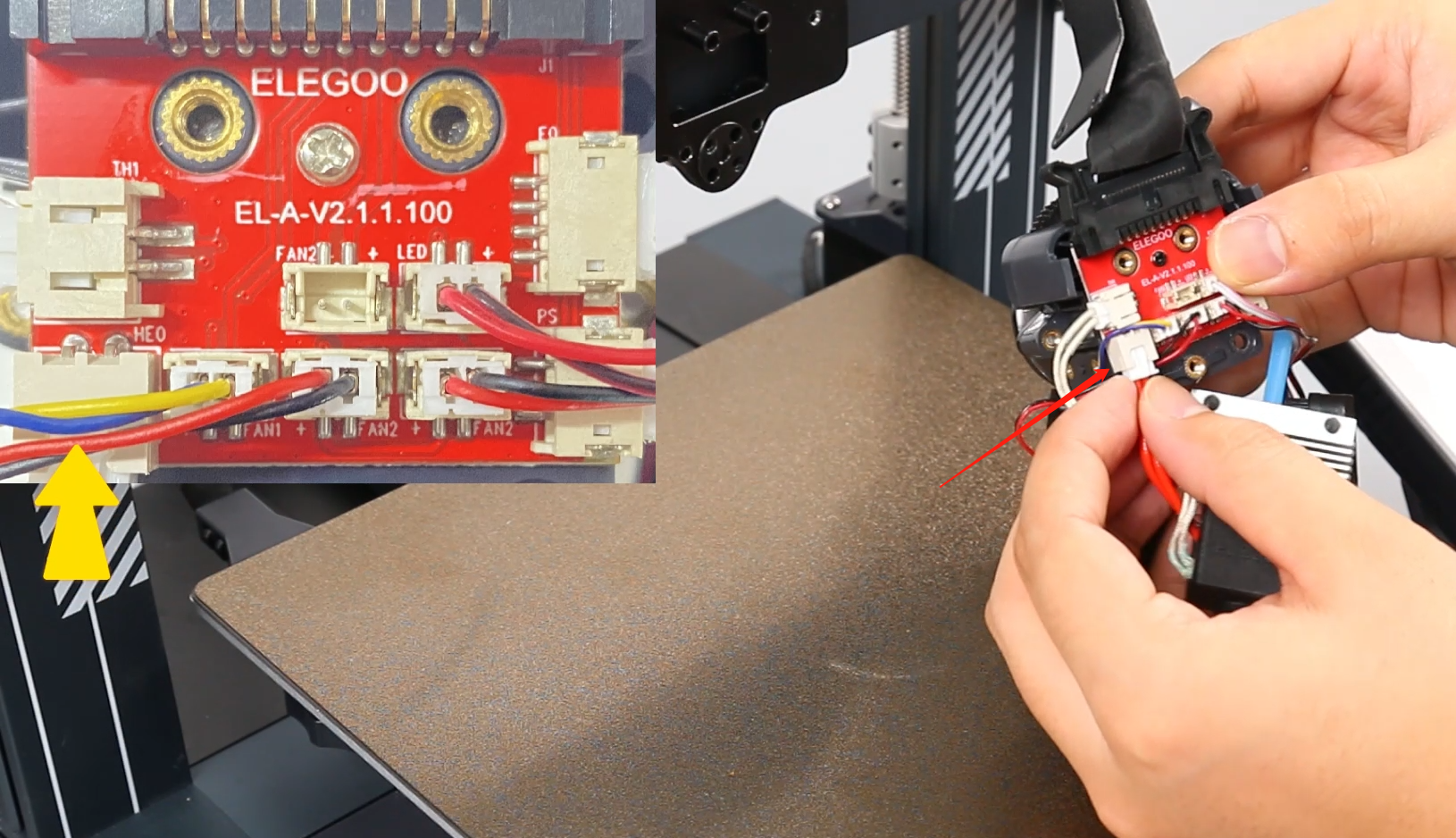

- Insert the cable port of the heater into the "HE0" port of the extrusion adapter board, take out the "connector", and use a 2.0mm hex wrench to tighten a set screw.

- Align the "fan bracket" assembly with the screw holes on both sides to install, and then insert the cable of the "proximity switch" into the PS port in the "extrusion adapter board".

- Install the front cover of the whole print head assembly (It has a groove design and can be installed by sliding it in).

3-Install the print head

- Place the whole print head assembly into the mounting position in front of the print head, and use a 2.0mm hex wrench to tighten the two fixing screws of the "print head front cover".

- Use a 2.0mm hex wrench to tighten the two fixing screws of the "cable fastener" and the two fixing screws of the print head.

- Take out the fan assembly, align it with the screw holes mounting position, use a 2.5mm hex wrench to tighten the three fixing screws of the rear fan assembly (install with the air outlet facing downward), and insert it into the fan assembly interface cable port.

- Power on the printer, and it can be used normally after re-leveling it.