When to adjust the eccentric wheel

●When the tool head slides abnormally and wobbles noticeably, the eccentric wheel of the X-axis slider assembly needs to be adjusted.

●When the hot bed slides abnormally and wobbles noticeably, the eccentric wheel of the Y-axis slider assembly needs to be adjusted.

Tools needed

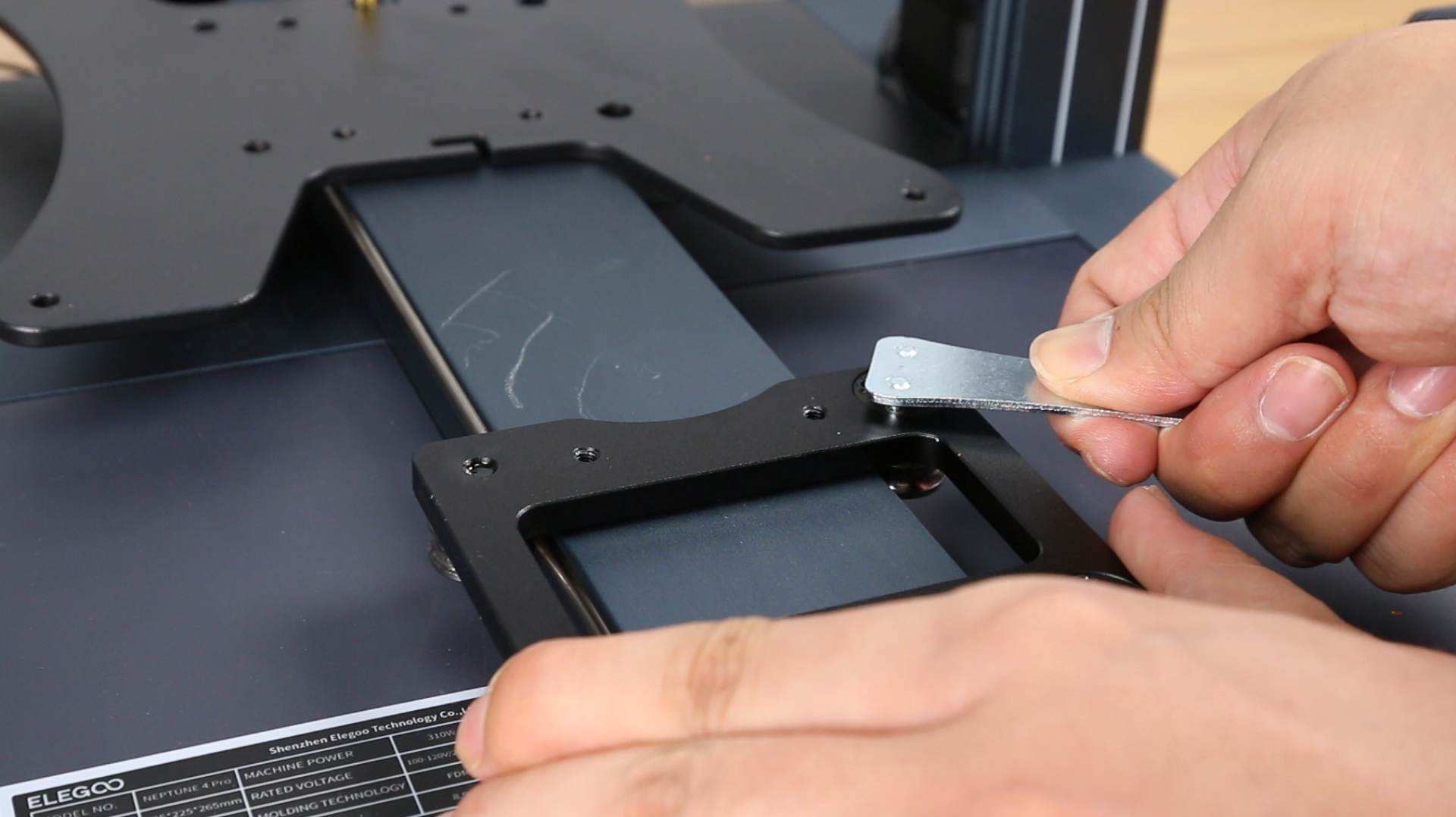

●Wheel adjustment wrench supplied with the machine

●2.0mm hex wrench

●2.5mm hex wrench

Reference video

Precautions before operation and machine status

This operation requires the disassembly of the tool head and hot bed. Before performing these operations, take all necessary precautions. Please turn off the machine and wait for the print head and hot bed to cool down completely.

¶ Adjusting the X-axis eccentric wheel

Operation steps

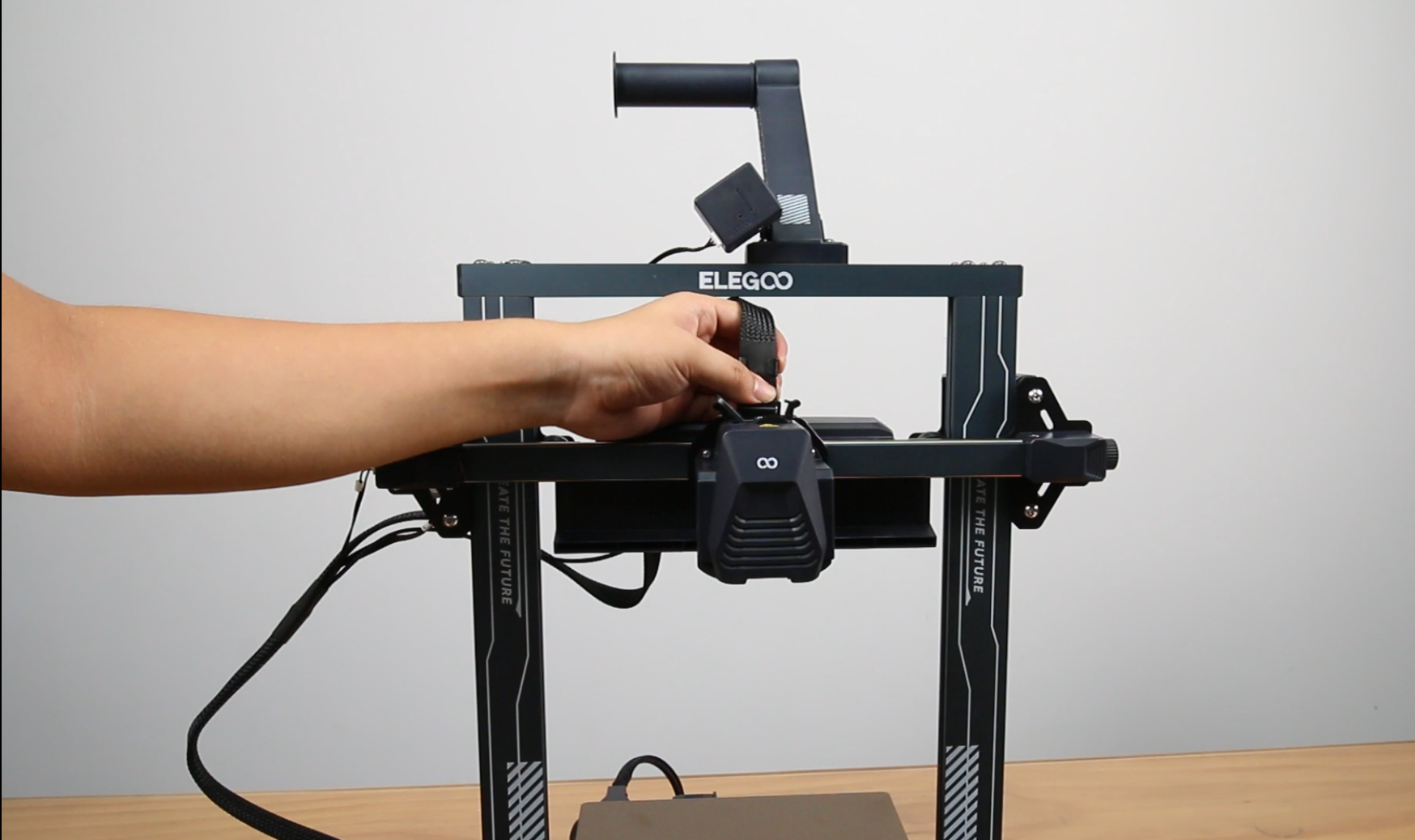

- Unplug the port cable of the fan assembly located directly behind the print head, use a 2.5mm hex wrench to loosen the three fixing screws of the "rear fan assembly", and remove the "rear fan assembly".

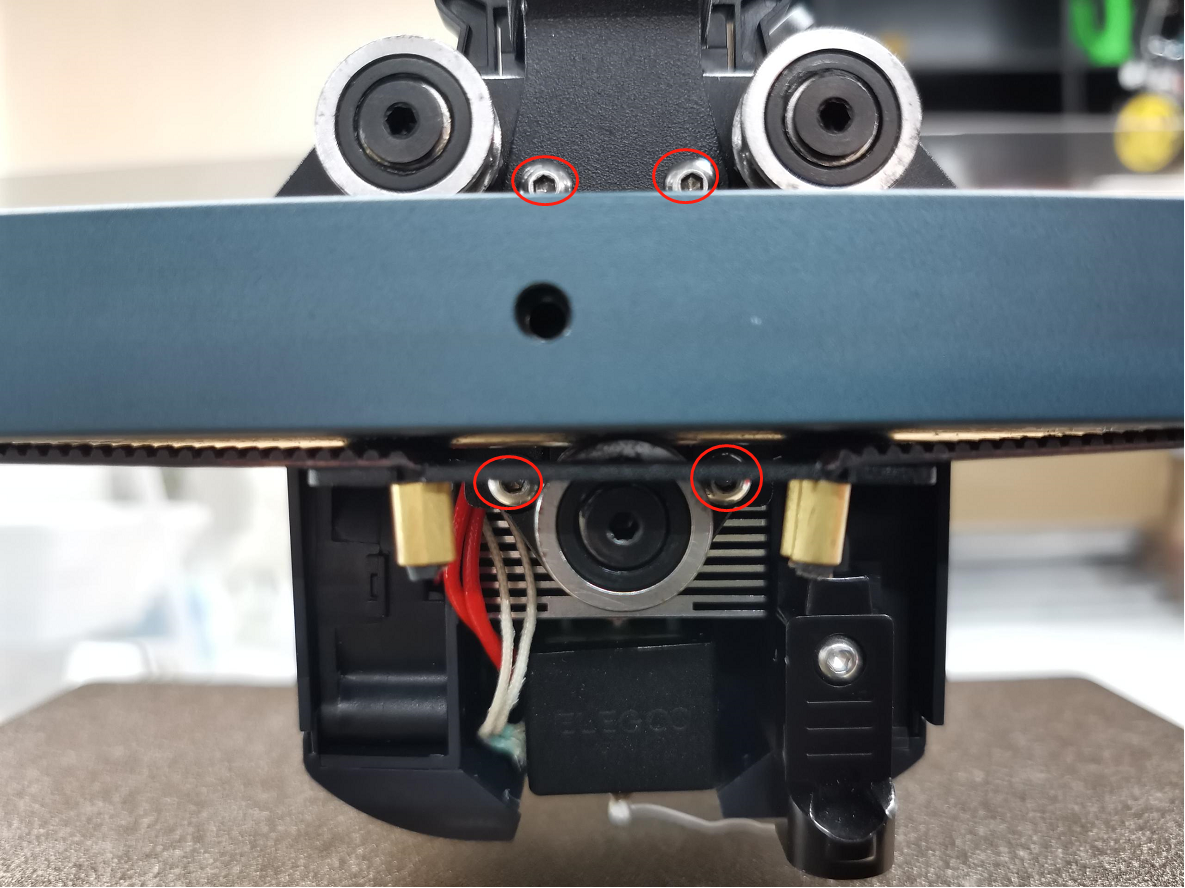

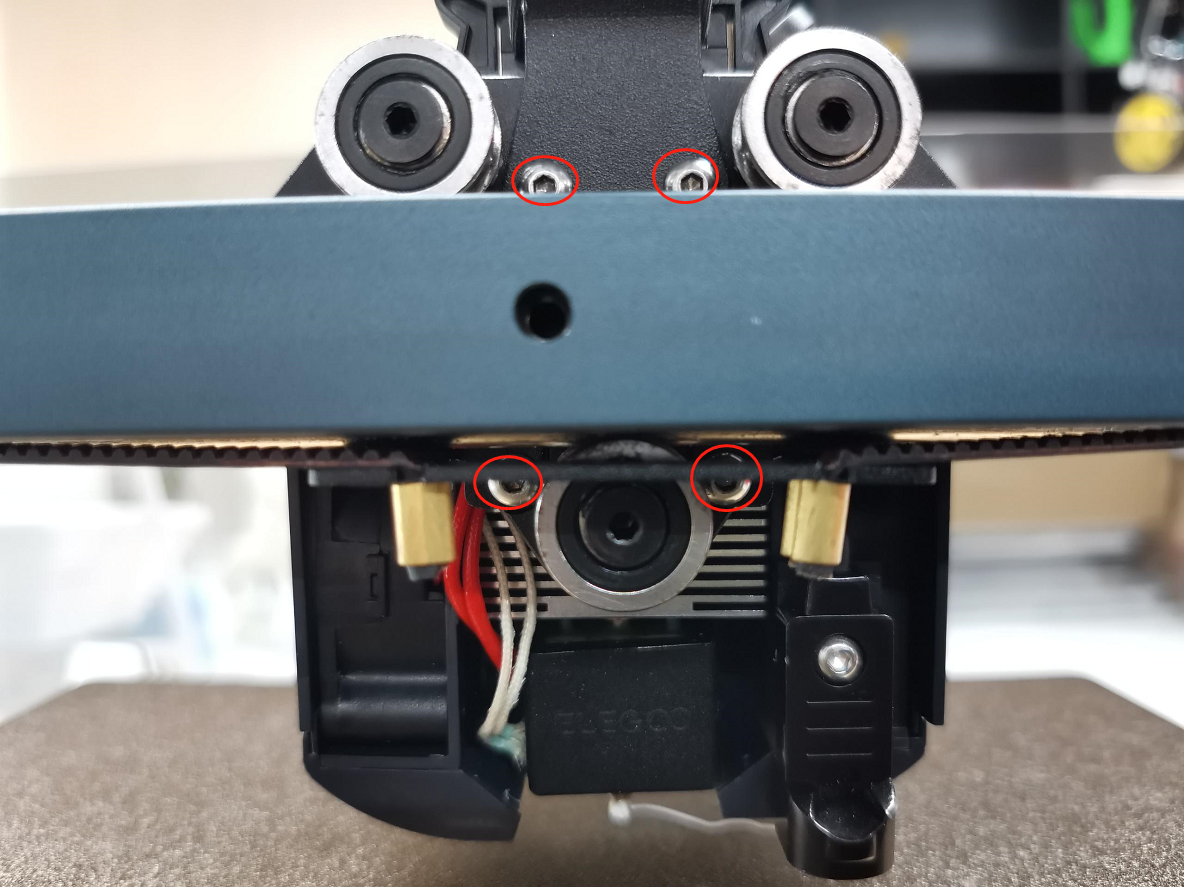

2. Use a 2.0mm hex wrench to loosen the two fixing screws of the "cable fastener" and the two fixing screws of the whole print head assembly.

3. Press the "horn terminal" on both sides with your hands, the print head cable will pop out automatically, and then take out the print head cable.

4. Use a 2.0mm hex wrench to loosen the two fixing screws of the "print head front cover" and remove the whole print head assembly.

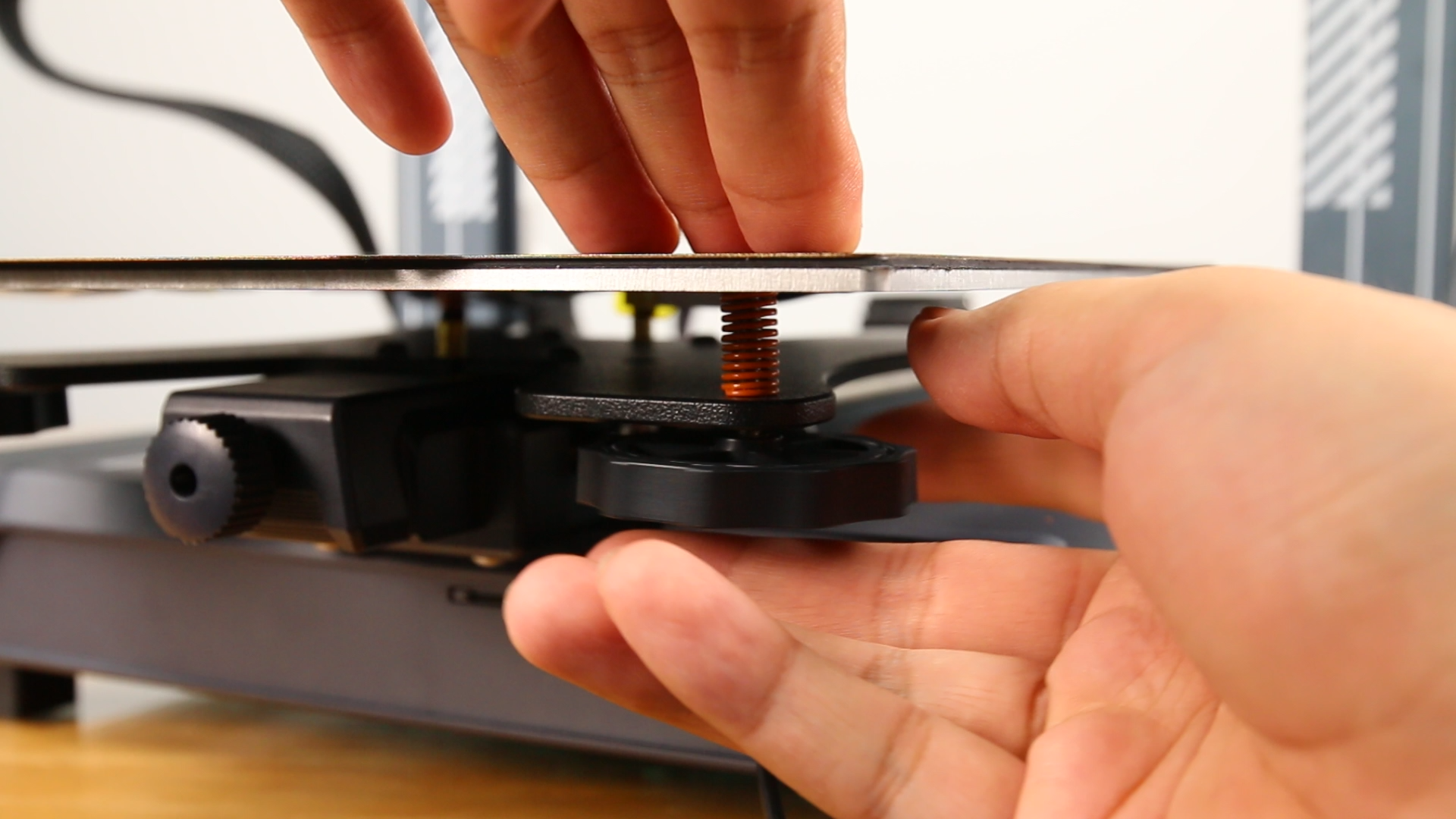

5. Check if there is obvious shaking in the X-axis slider assembly. Use a special wheel adjustment wrench to tighten the eccentric wheel. Adjust the eccentric wheel to not shake randomly and run smoothly, not too loose or too tight.

6. Place the whole assembly of the print head into the mounting position in front of the print head, and use a 2.0mm hex wrench to tighten the two fixing screws of the "print head front cover".

7. Press the "horn self-locking terminal" to both sides with your hands to open the port, and then insert the print head cable into the port (the cable passes under the top profile).

8. Use a 2.0mm hex wrench to tighten the two fixing screws of the "cable fastener" and the two fixing screws of the print head.

9. Align the fan assembly to the screw holes mounting position, and use a 2.5mm hex wrench to tighten the three fixing screws of the fan assembly (install with the fan mouth facing downwards).

¶ Adjusting the Y-axis eccentric wheel

Operation steps

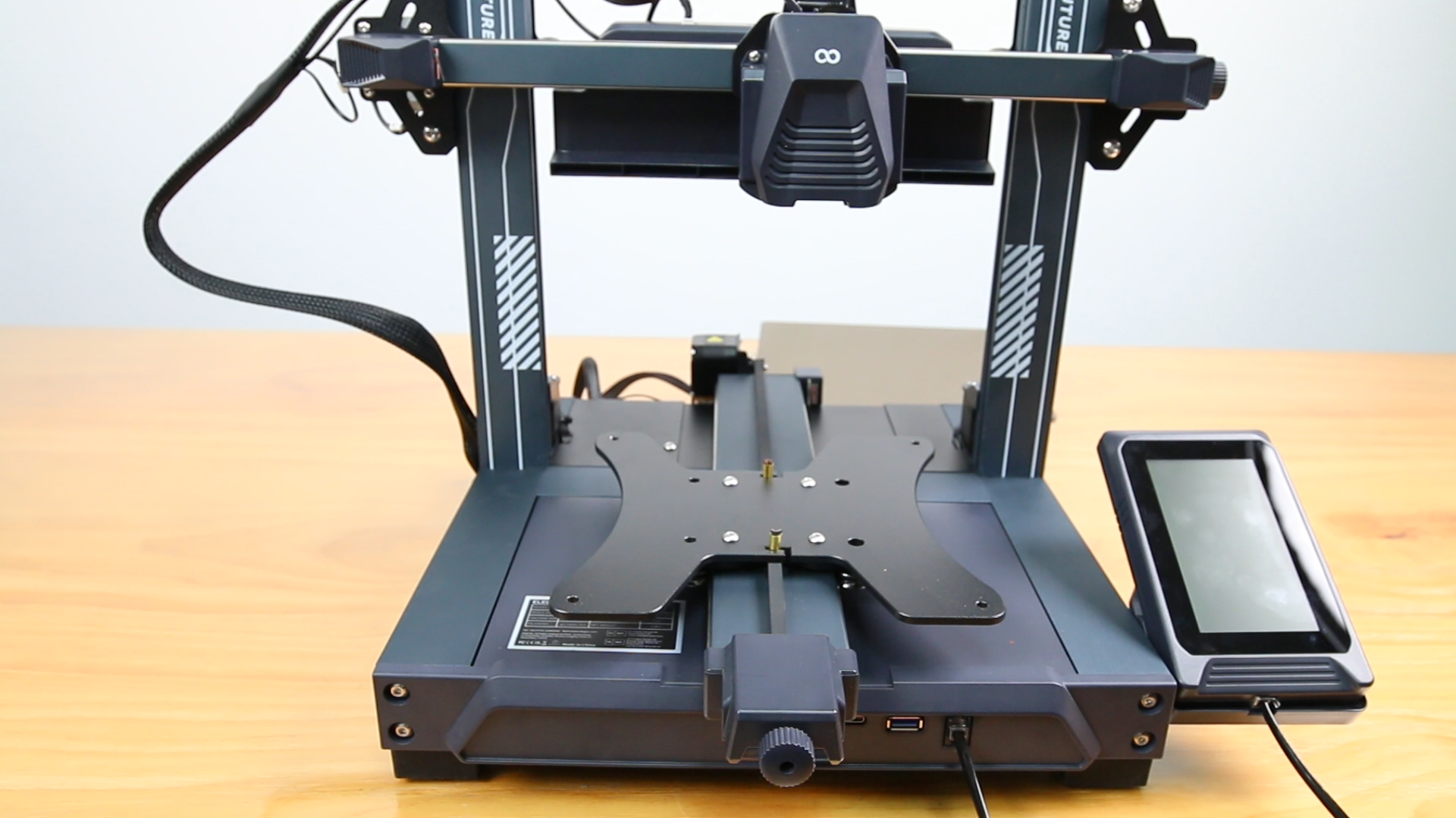

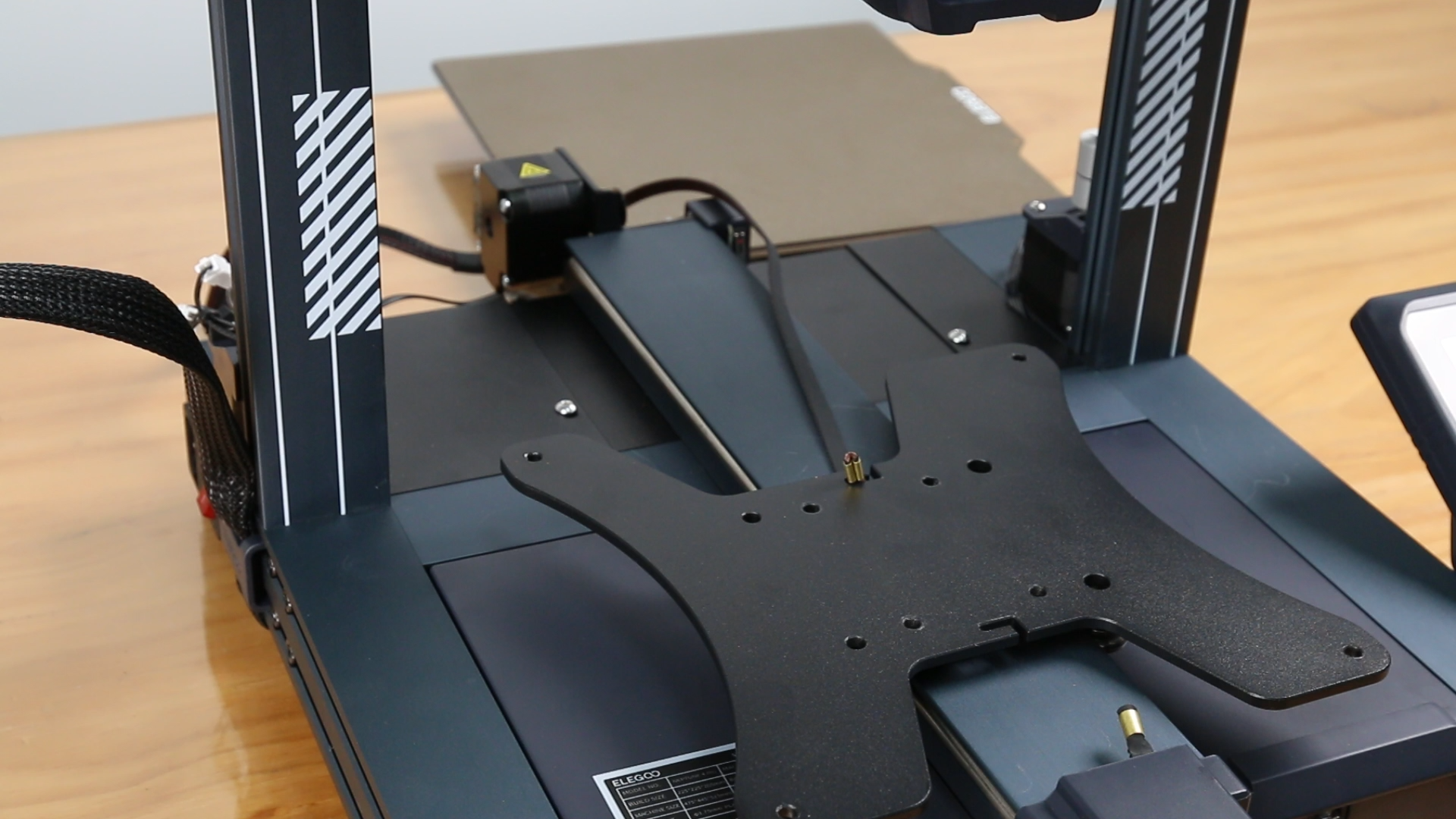

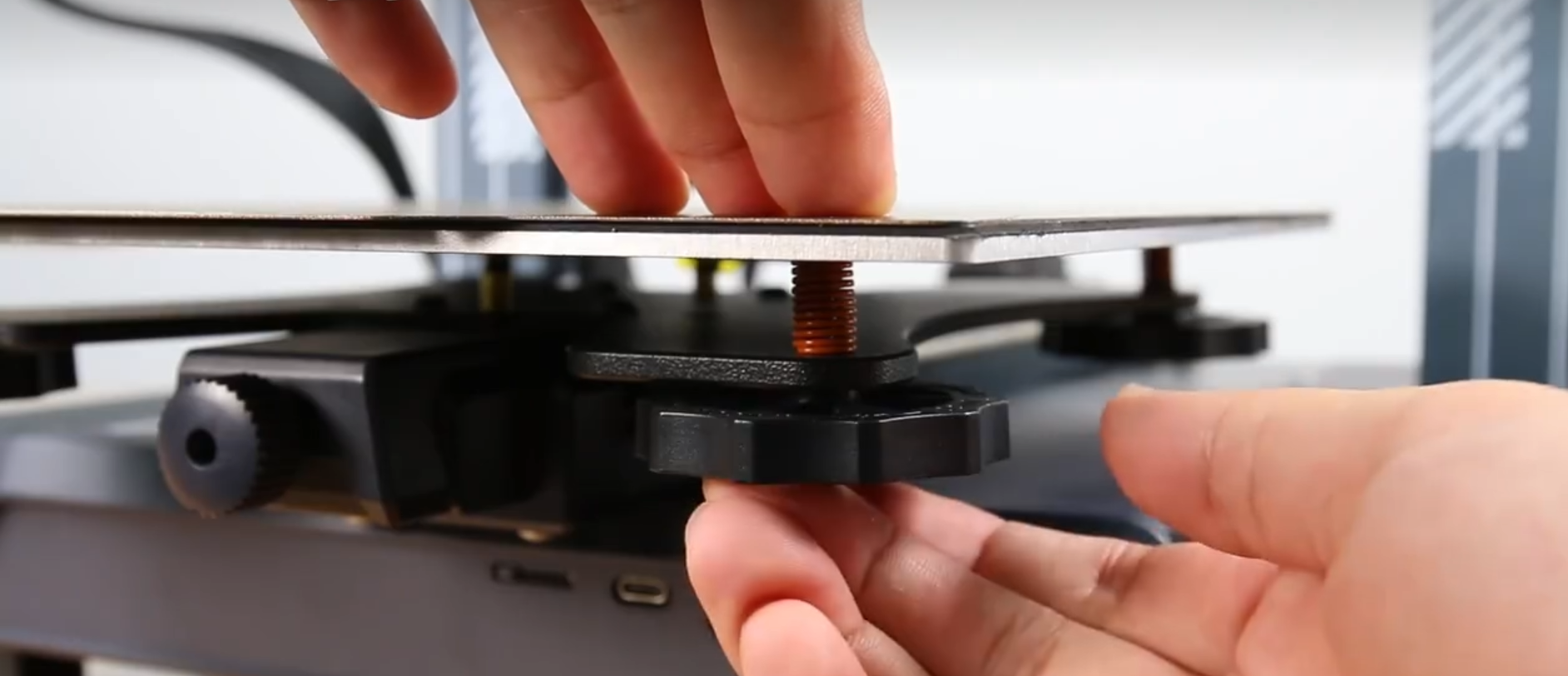

- Loosen the four leveling knobs, place the whole hot bed behind the machine, and remove the four leveling springs.

2. Loosen the knob of the Y-axis belt tensioner and remove the front end of the Y-axis belt from the printing platform bracket.

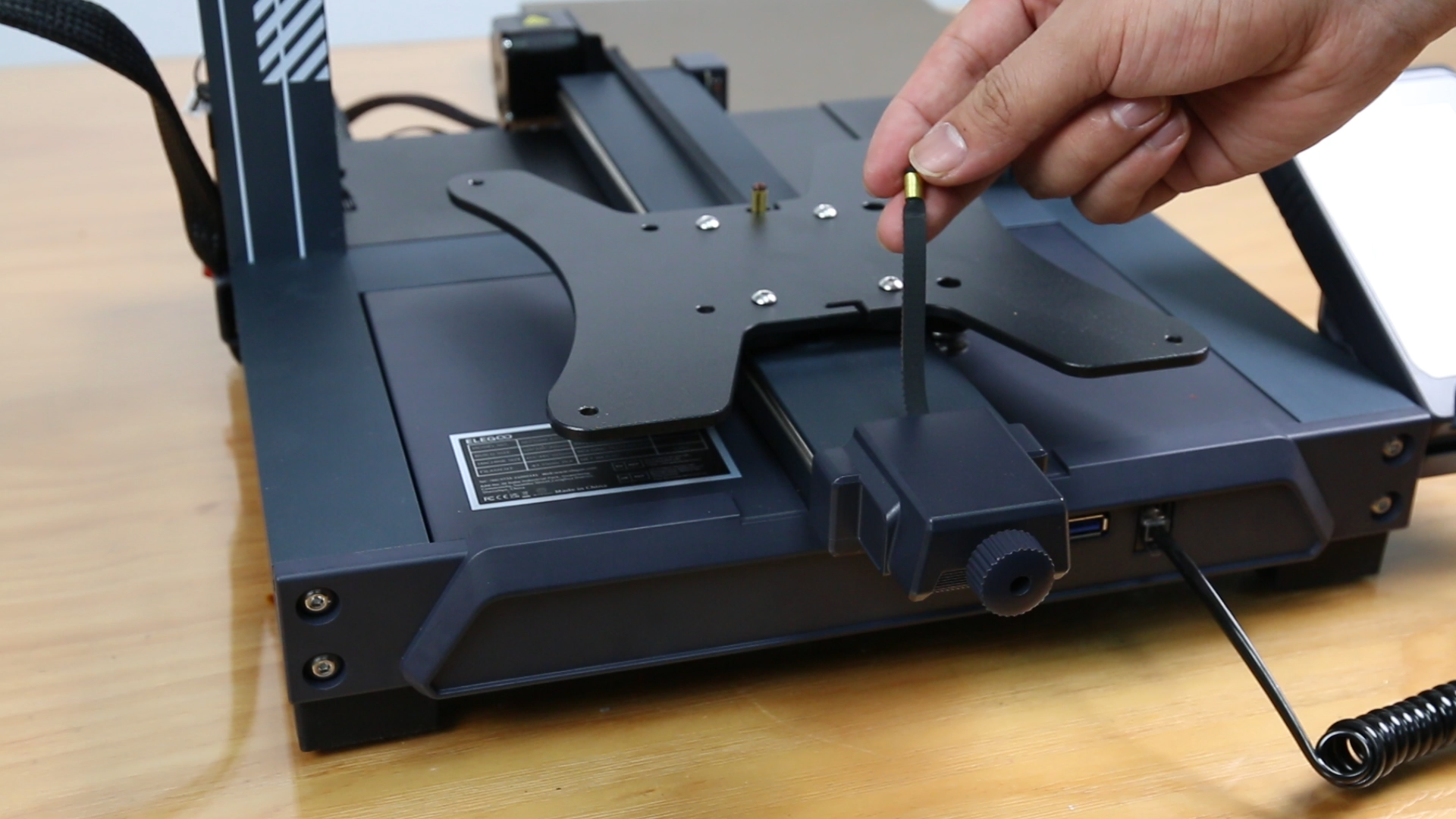

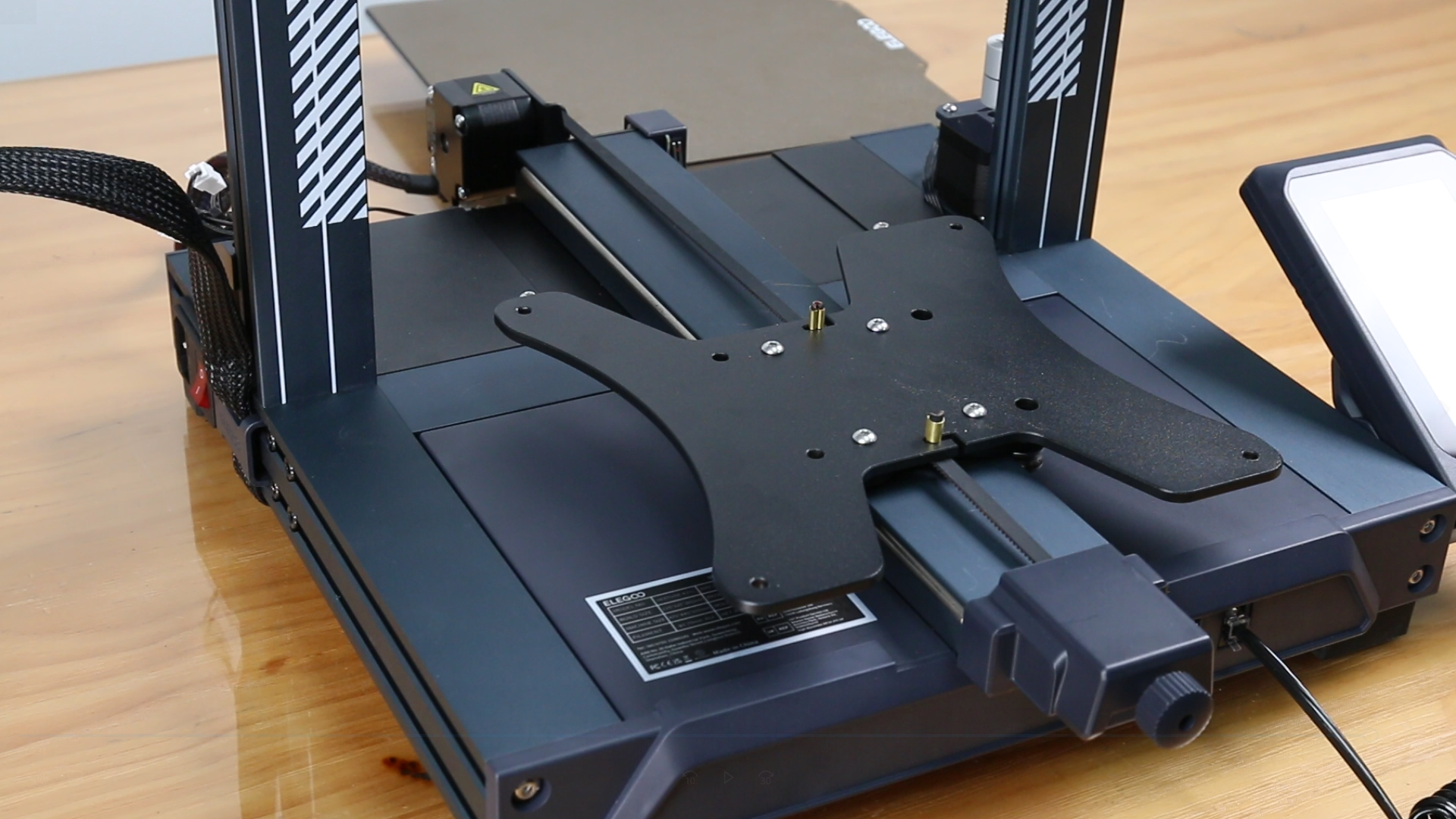

3. Use a 2.5mm hex wrench to loosen the four fixing screws of the printing platform bracket, and place the printing platform bracket behind the machine.

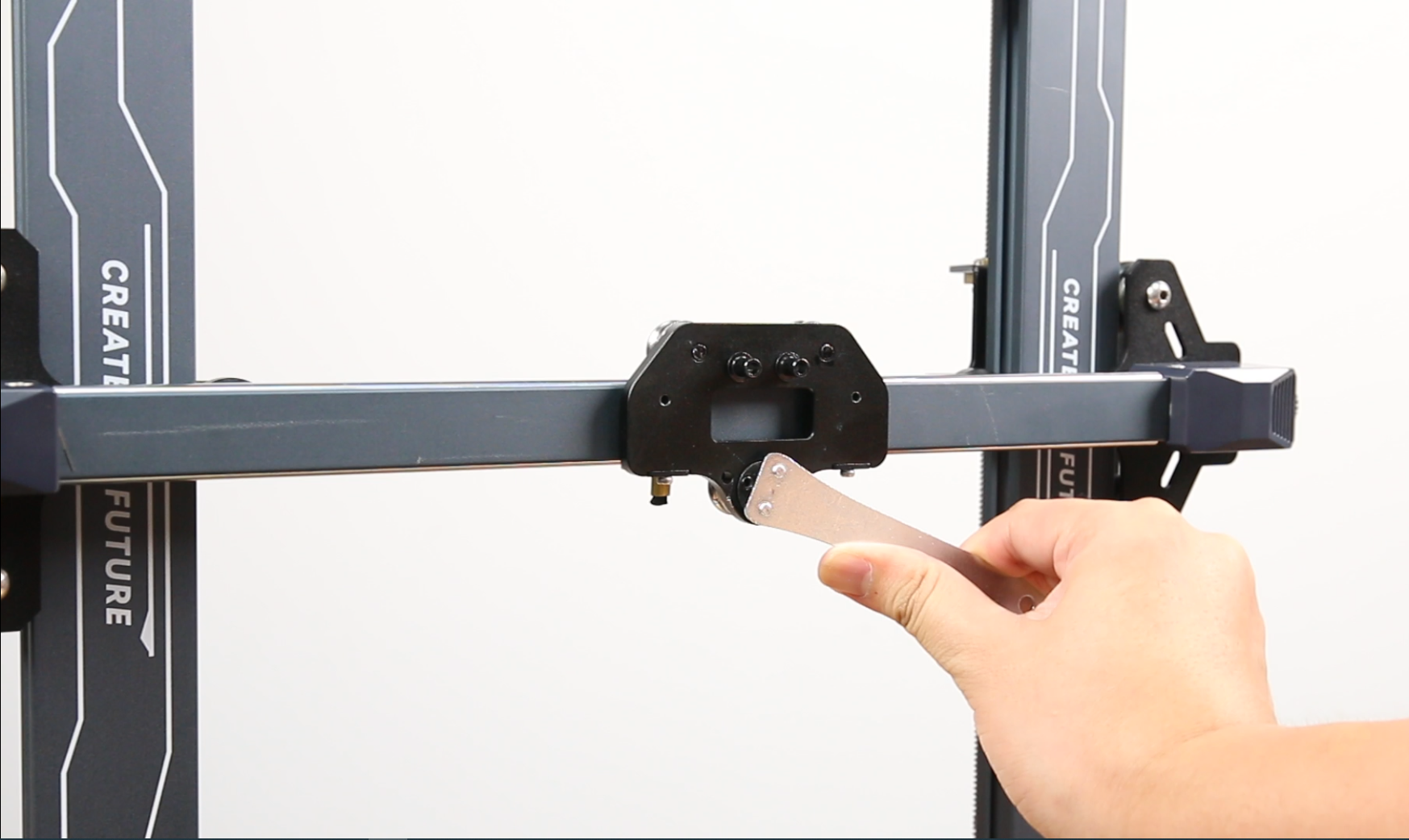

4. Check if there is obvious shaking in the Y-axis slider assembly. Use a special wheel adjustment wrench to tighten the two eccentric wheels (the two eccentric wheels need to be adjusted synchronously), and adjust the eccentric wheels to not shake randomly and run smoothly, not too loose or too tight.

5. Place the printing platform bracket into the mounting position, align the screw holes, and use a 2.5mm hex wrench to tighten the four fixing screws of the printing platform bracket.

6. Hang the rear end of the belt on the Y-axis motor gear, and then snap the front end of the belt into the belt groove of the printing platform bracket.

7. Turn the knob of the Y-axis belt tensioner and adjust it until the belt tension is moderate, not too loose or too tight.

8. Place the four leveling springs into the mounting position, place the whole hot bed above the springs, insert the four leveling screws into the four springs, and tighten the four leveling knobs.

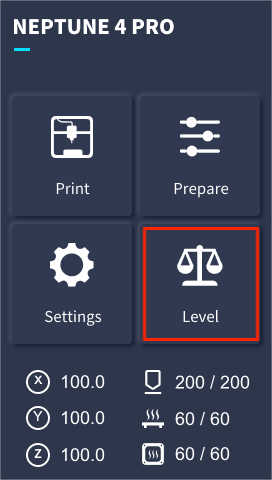

9. Power on the machine. Perform manual leveling and automatic leveling again, and it can be used normally.