Categories English Full Name Introduction Figure Legends

printer Mars

5.5 inch 2K heterochromatic LCD, size: 68.04*120.96*150mm

Mars Pro

5.5 inch 2K heterochromatic LCD, size: 68.04*120.96*150mm

Mars 2

6.08 inch 2K mono LCD, size: 82.62*130.56*150mm

Mars 2 Pro

6.08 inch 2K mono LCD, size: 82.62*130.56*160mm

Mars 3

6.6 inch 4K mono LCD, size: 143.43*89.6*175mm

Mars 3 Pro

6.6 inch 4K mono LCD, size: 143.43*89.6*175mm

Mars 4

7 inch 9K mono LCD, size: 153.36*77.76*175mm

Mars 4 Ultra

7 inch 9K mono LCD, size: 153.36*77.76*165mm

Mars 4 DLP

DLP imaging technology, size: 132.8x74.7x150mm

Mars 5

6.6 inch 4K mono LCD, size: 143.43*89.6*150mm

Mars 5 Ultra

7 inch 9K mono LCD, size: 153.36*77.76*165mm

Saturn

8.9 inch 4K mono LCD, size: 192*120*200mm

Saturn S

9.1 inch 4K mono LCD, size: 196.704*122.88*210mm

Saturn 8K

10 inch 8K mono LCD, size: 218.88*123.12*210mm

Saturn 2

10 inch 8K mono LCD, size: 218.88*123.12*250mm

Saturn 3

10 inch 12K mono LCD, size: 218.88*122.88*250mm

Saturn 3 Ultra

10 inch 12K mono LCD, size: 218.88*122.88*260mm

Saturn 4

10 inch 12K mono LCD, size: 218.88*122.88*220mm

Saturn 4 Ultra

10 inch 12K mono LCD, size: 218.88*122.88*220mm

Jupiter

12.8 inch 6K mono LCD, size: 277.848*156.264*300mm

Jupiter SE

12.8 inch 6K mono LCD, size: 277.848*156.264*300mm

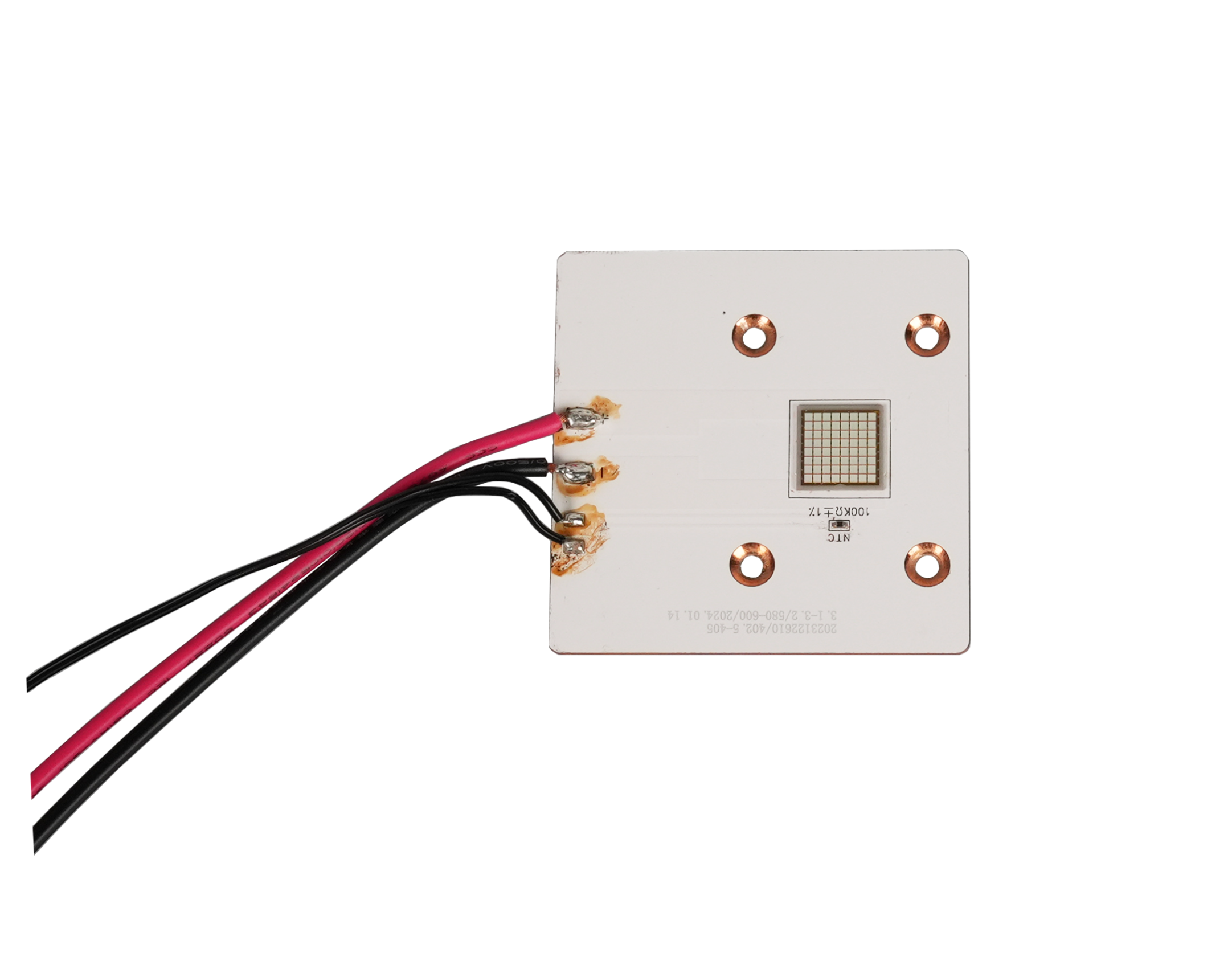

light light board

Light board,fixed at the bottom of printers, is an optical component emiting ultraviolet light of specific wavelength.

lens

Lens, optical component, is fixed above the LED light board to adjust the shape of light.

heat disspation system of light borad

Heat disspation system of light board is fix under the LED light board to cool down the light board.

light shield

Light shield is fixed above the LED light board to cover and restrict the illumination area.

fresnel lens

Fresnel lens, installed on some of the printers, is fixed under the LCD screen to straighten the light.

fan cooling fan

Cooling fans are fixed inside the printers to dissipate the heat.

main structure build plate 3D Models are produced on the build plate.

cover

A cover can shield 3D models from ultraviolet.

Z-axis plate

The Z axis plate is at the back of the printer with moving components installed on it.

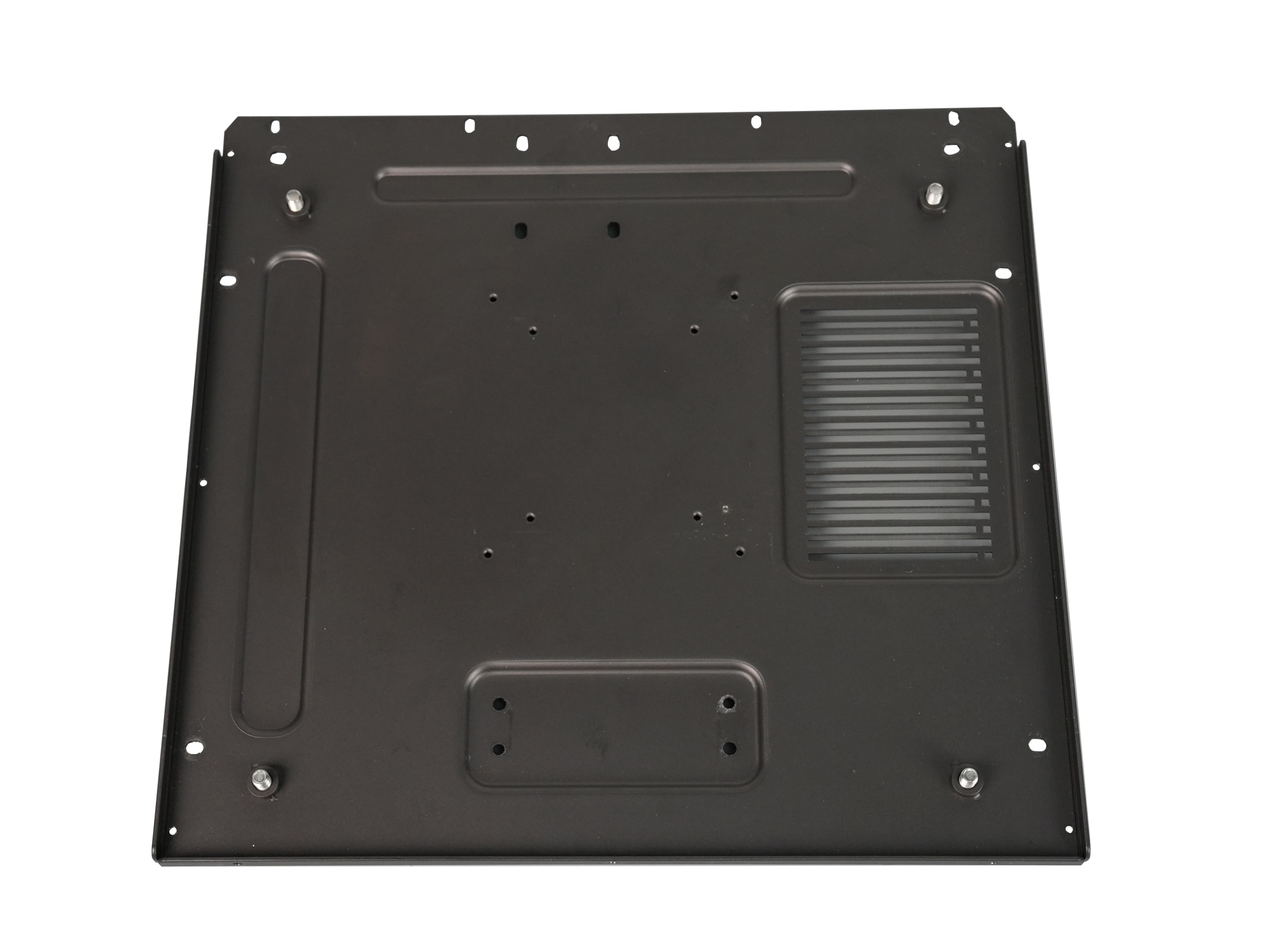

middle plate

The middle plate, located at the middle part of the printer, containing main components and the LCD screen.

outer shell

The housing can decorate and protect the printer's inner parts.

base

The base is installed at the bottom with several parts inside.

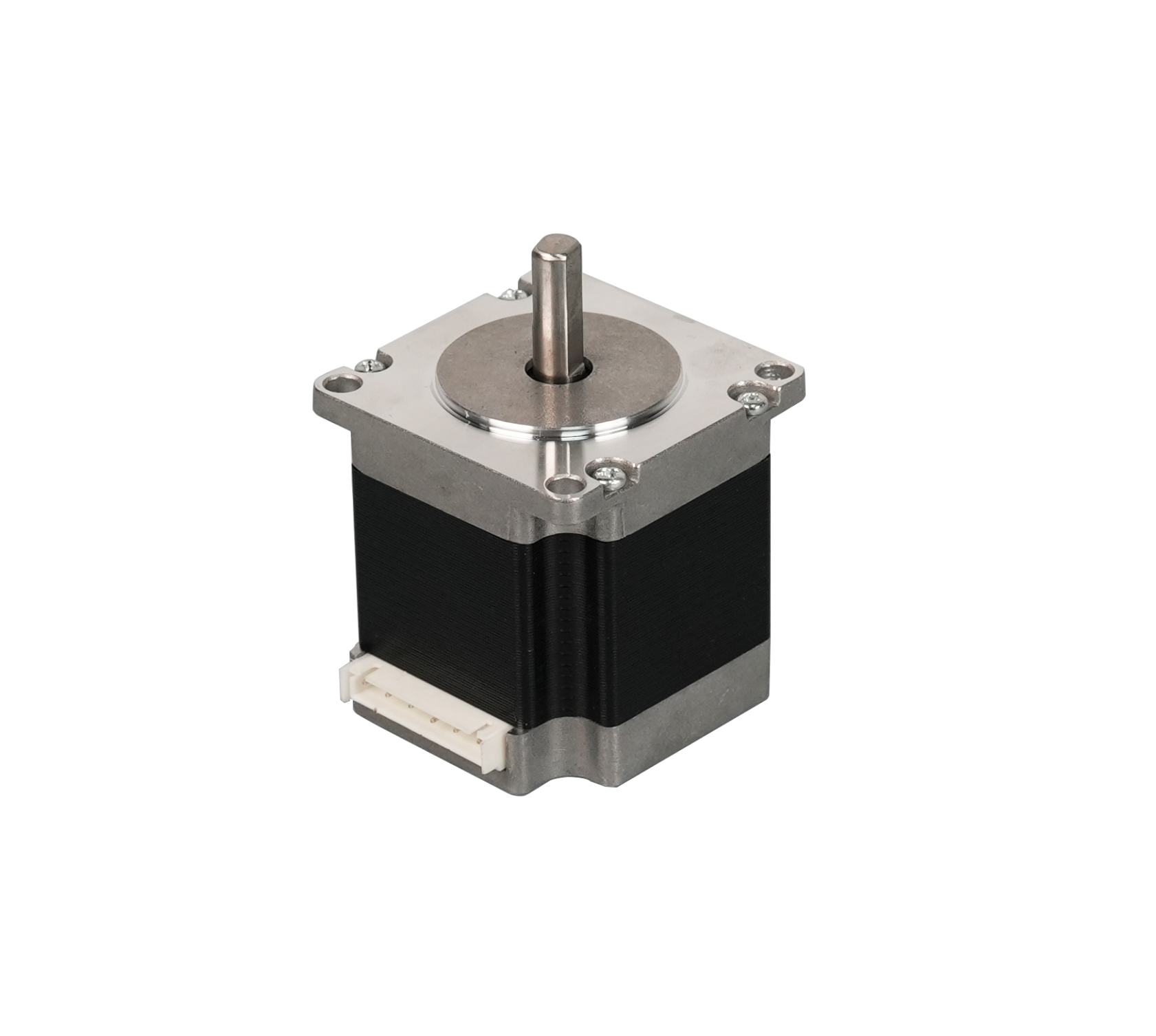

Z motor

The Z motor powers the print platform to move up and down.

release motor

The release motor can title LCD screen.

linear guide

The linear guide controls the Z axis move up and down.

air purifier The air purifier can filter the air by adsorbing VOC.

auto feeder

The auto feeder can feed and recycle the resin automatically.

WiFi antenna

The WiFi antenna receive the wifi signal.

camera

The camera has AI monitoring function, real-time monitoring function and time-lapse phtograpy function.

adaptor

The adpater is voltage converting device, providing electrical energy for the printer.

limit switch

The limit switch is signal trigger to ensure the devices are in place.

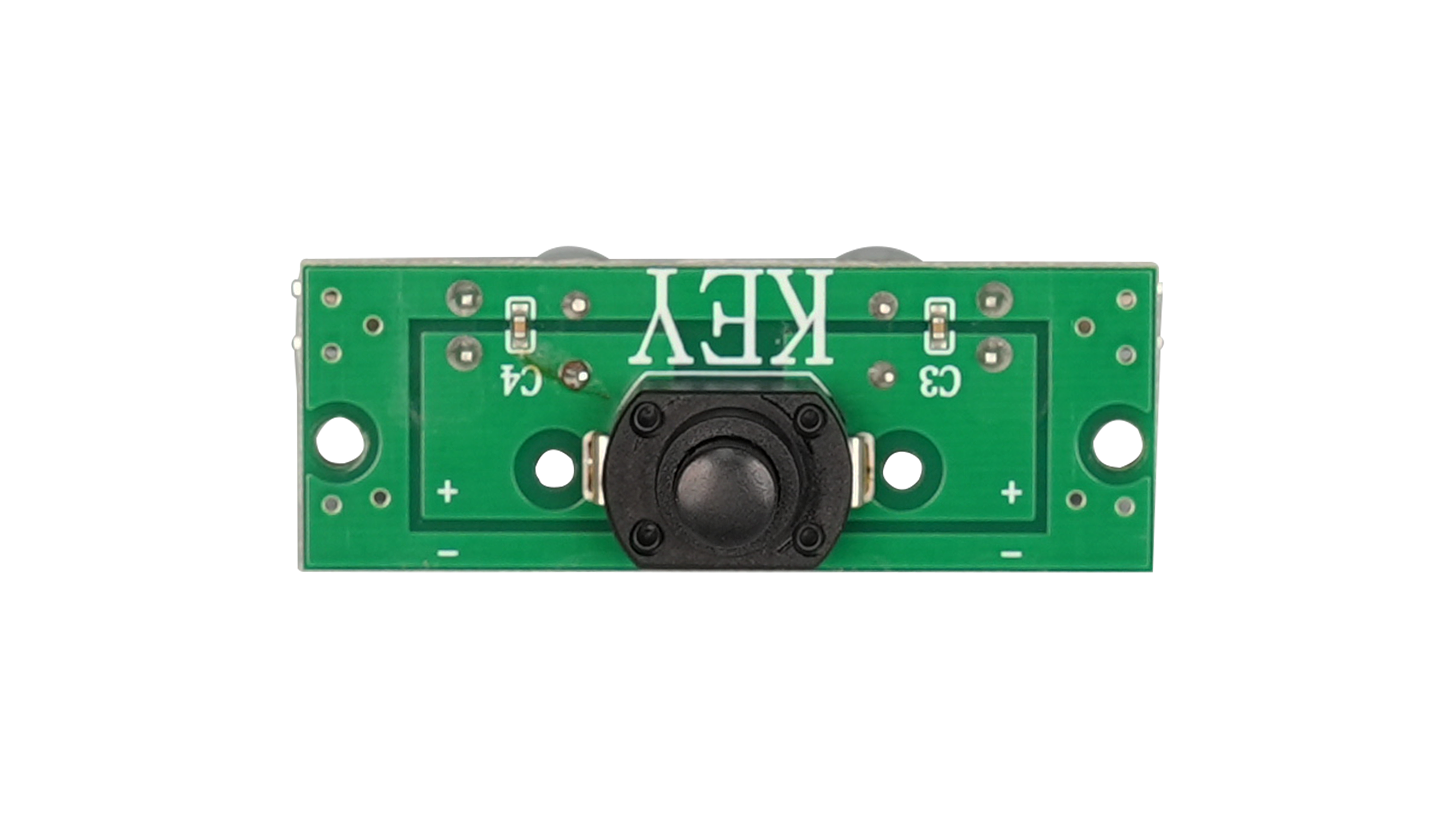

electrical components main board

The main board is the core of the printer, controlling the electrical.

constant current board

It is a drive board providing constant current for UV light.

PCB interface board of air purifier

The interface connects the air purifier with the printer.

PCB board of power supply

Only some of printers has the PCB board of power supply.

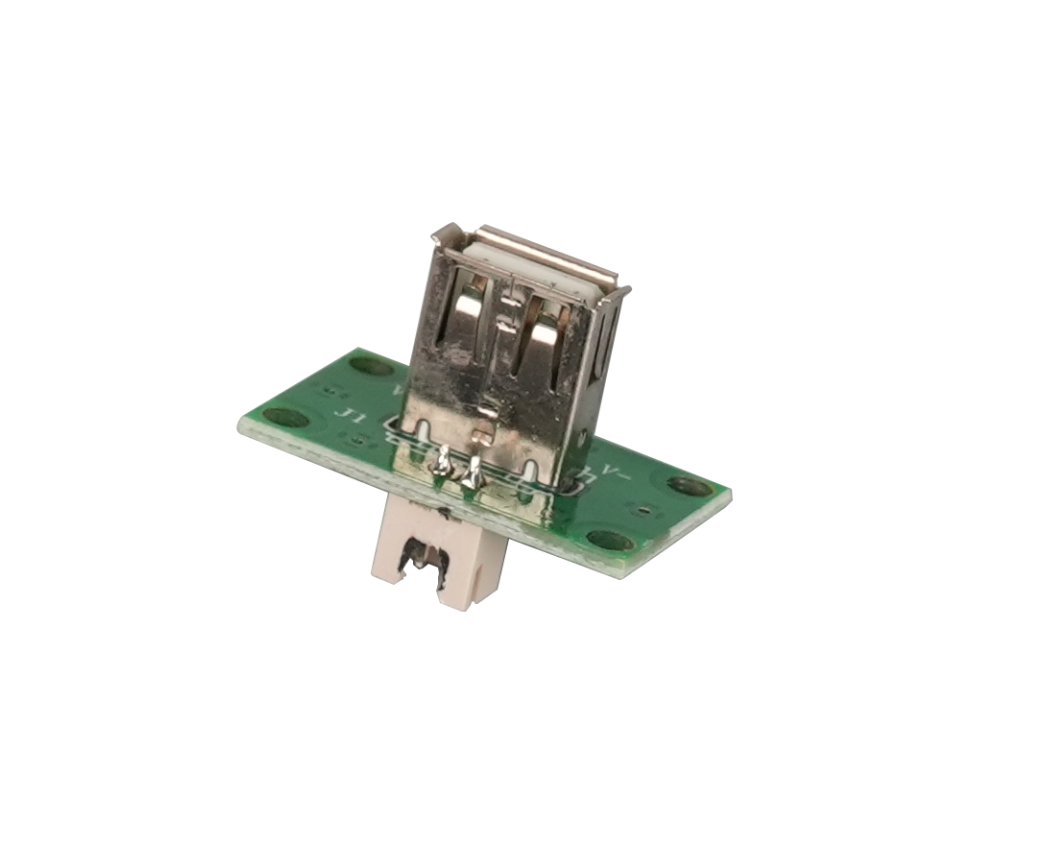

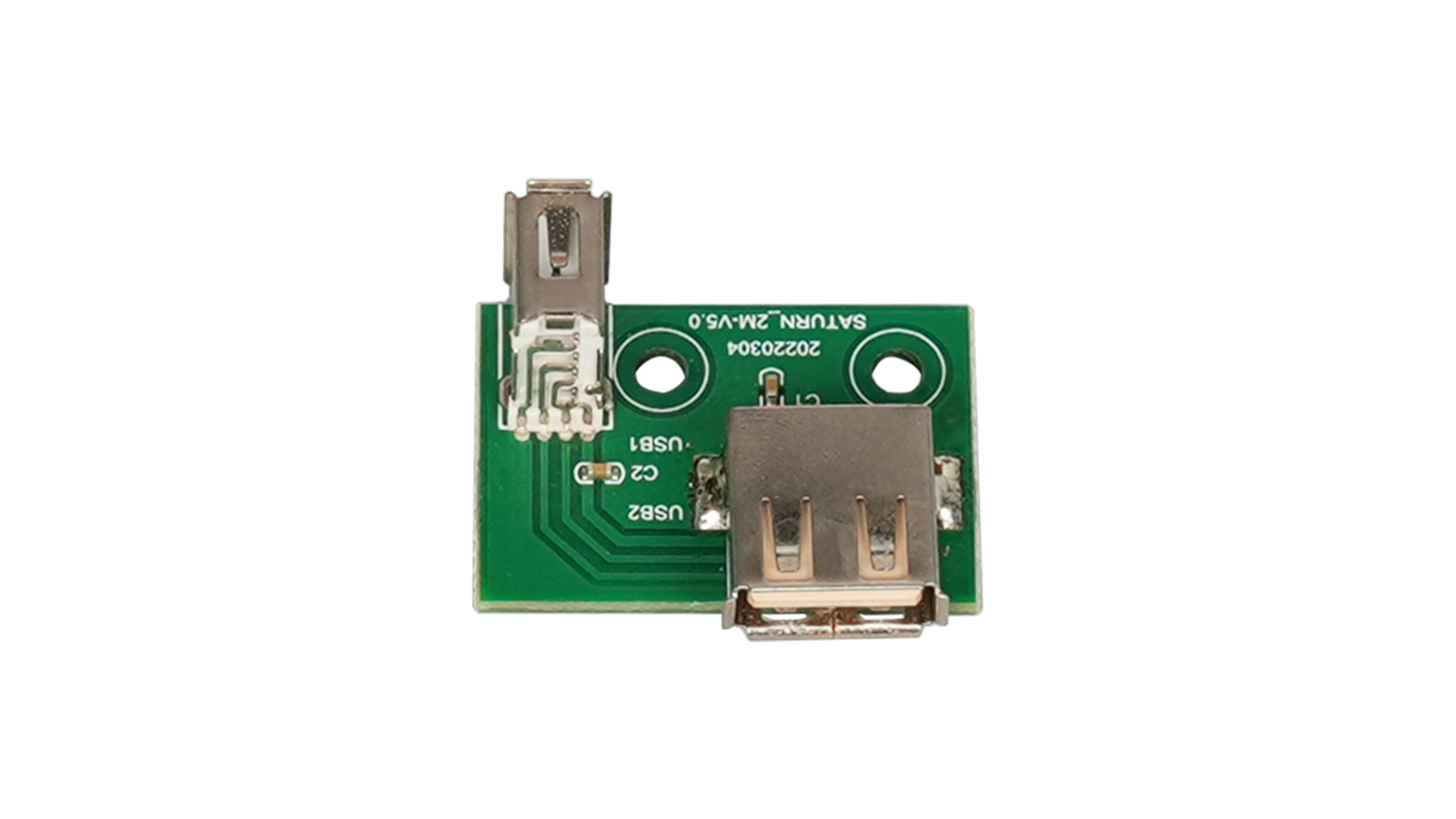

USB adapter board

The USB adapter board converts to circuit board.

touch screen

The touch screen is a display screen used to control the printer.

resin tank / VAT resin tank / VAT The resin tank is a container of resins.

tabletting sheet

It is located at the bottom of the resins tank, used to fix the release film.

knurled handle

The screw is used to fix the resin tank with the printer.

screw fixing block

Some of the printers has the screw fixing block installed inside the middle plate to fix the knurled handle.

release film As UV lights can penetrate the release film, it is used to demould the models and store resins. The most frequently used categories include FEP/PFA/ACF.

resin collection tank

The resins collection tank is a part assisting in demoulding and preventing the resins from dripping on the surface.

LCD LCD screen The LCD screen is installed on the middle plate, used for displaying the pattern of models.

LCD screen cable

The LCD screen cable is communication cable connects the LCD screen with main board.

parts illumination lamp

The illumination lamp produces light for the printer.

U disk

U disk can save model files.

nitrile gloves

The nitrile gloves can prevent skin from direct contact with resins during post processing.

mask

Waring mask can protect users against peculiar smell.

paper funnel

The paper funnel can filer the residues of resins.

tool package

The tool package includes installing tools and spare parts.

metal shovel

The metal shovel can remove models from print platform.

plastic shovel

The plastic shovel can check whetehr there is any residues in the resin tank.

UV-curing photopolymer resin rigid resin

Rigid resin belongs to basic resin with high hardness and fragility.

ABS-like resin

ABS-like resin has high toughness.

water washable resin

The resin is odourless and eco-friendly. It can be washesd in water.

rigid plant-based photopolymer resin

Because the resin is made of extractive of soybeans so it is gentle to skin and eco-friendly.

thermochromic resin

The resin is sensitive to temperature and can change its color if the temperature is above 50 degree celsius.

8K rigid photopolymer resin

The resin has high resolution and good performance of details.

8K water washable photopolymer resin

The resin is odourless and can be washed in water. It has good performance of details.

dental UV resin

The dental resin is categoried into orthodontics, restoration and casting. It is exclusively used in dentistry.

rapid rigid photopolymer resin

The resin can be used with high-speed printers to improve printing efficiency.

print quality models dropping from print plate

The printing failed as the model is sticked onto the resin tank.

a layer of model is sticked to the release film

The model failed to demould since a thin layer of model is sticked to the release film.

holes on surface

The model has some holes or pits on its surface.

cracks on surface

The model has some cracks on its surface after placing for a period of time.

bulge on surface

The model is layered inside and the surface bulged.

model parts get lost

The surface of the model got lost, looking like pits, holes and cracks.

kelp-like floatage

It refers to the floatage existing in the resin or the flakes and floccules on the model or supports.

malposition of layers

The model has malposition of layers when horizontal layers being printed.

edge warping

It refers to that the bottom of the model didn't stick totally to the print plate and the edge wraped during printing.

support seperating

It refers to that the support didn't stick to the model, leading to failure of the printing.