¶ Description

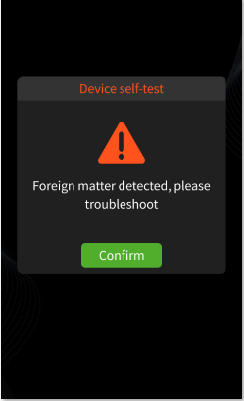

During the pre-print device self-check or printing process, the printer displays an error message stating “Foreign matter detected, please troubleshoot.”

¶ Reasons

- The printer is either installed on unstable ground or positioned in close proximity to an vibrating equipment.

- Following a failed print, the excess cured resin in the resin tank was not promptly cleared.

- During printing, the resin is exposed to strong light and then cure.

- The build plate is installed improperly, or the build plate surface is contaminated.

- The resin is excessively high in viscosity, causing false triggering.

- The wiring or adapter board of the mechanical sensor has abnormalities.

¶ Solutions

- Ensure the printer is placed on a stable, level surface, and away from sources of vibration.

- Following a failed print, promptly remove any excess and cured resin. During printing, avoid exposure to strong light to prevent additional curing caused by resin photopolymerisation.

- Regularly inspect and tighten all relevant fixing screws on the build plate. Prior to printing, clear any cured residue and burrs from the surface.

- Check whether the connection between the sensor and the adapter board is loose or damaged. Replace the wiring or adapter board with a new one if necessary.

- Avoid using high-viscosity resins. Should the resin viscosity prove excessively high, manually heat the resin, or use heating equipment to reduce its viscosity.

Should the issue persist, copy the Exporting.gcode file to the root directory of the USB drive.

NOTE: Do not alter the filename or place it within any folders.

Insert the USB drive into the printer, and click Print. Upon completion of the print, a file named 100MachineParams.gcode will be generated on the USB drive.

Submit this file to the ELEGOO after-sales team via Support – ELEGOO Official, specifying the resin type and viscosity value currently in use.