¶ What does it look like

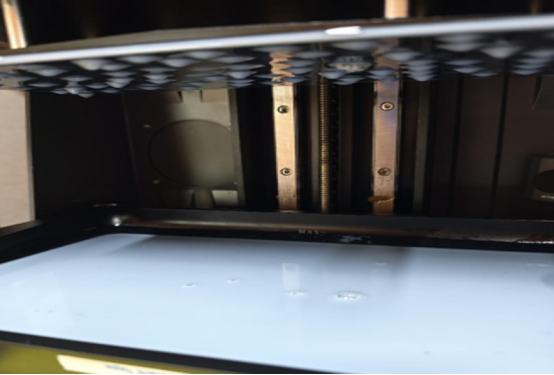

¶ Issue Description 1: The model doesn't stick to the build plate

The print is detached from the build plate. Sometimes, only a thin sheet is attached to the surface of the release film in the resin tank. Or the print with a certain height is attached to the release film.

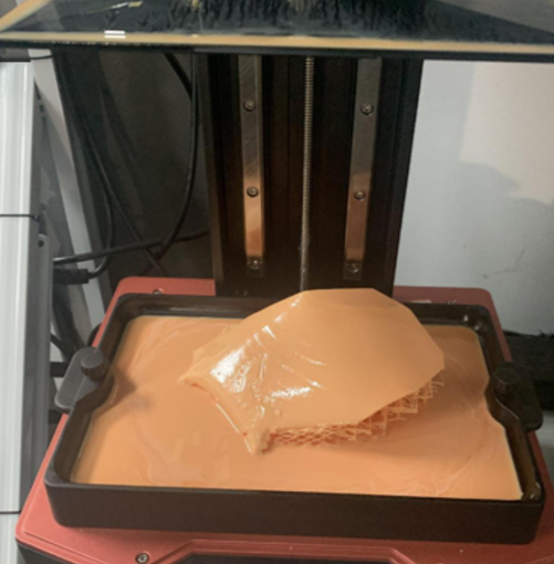

¶ Issue Description 2: Warping

The bottom of the print is warped. It can result in print’s insufficient adhesion to the build plate model, or even break away from the plate.

¶ Issue Description 3: Uncured model

No cured product is generated on the surface of the build plate and the release film.

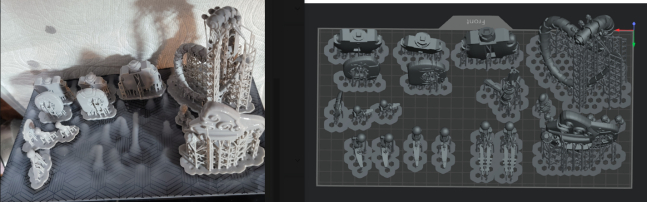

¶ Issue Description 4: Holes and gaps in the model

The print has structural defects or holes due to missing or deformed supporting structures, affecting the overall shape and function of the print.

¶ How to fix

¶ Leveling calibration

Check the printer leveling and fine-tune the uneven leveling gap through the leveling screws. Ensure the build plate is parallel to the screen, enhancing the adhesion between the print and the build plate.

¶ Surface cleaning

- Clean the resin residue on the surface of the build plate/LCD screen/release film using alcohol.

- Polish the burrs on the surface of the build plate using sandpaper if necessary.

- Replace the release film with a new one if the release film is loose or scratched in order to prevent resin leakage.

¶ Exposure detection

- Check whether the LCD screen has dark spots, bright lines, etc. If it has any display faults, replace the LCD screen with a new one.

- Clean up the resin residue and dust on the surface of the screen. Ensure that the light penetrates evenly.

¶ Light source detection

- Check whether the light source intensity is normal, and whether there is any aging or attenuation.

- Check whether the light inside the printer is not obstructed and ensure that the light can fully hit the resin surface.

¶ Environmental condition optimization

It is recommended to use the ambient temperature at 25 - 30℃ (77 - 86 ℉).

¶ Parameter adjustment

Reset the print setting parameters according to the characteristics of the resin.

Note: Before printing, it is recommended to preheat the resin, increase the exposure time (of the bottom/normal layer), and the rest time and lifting height after printing.

If the temperature of the printing environment is too low, the viscosity of the resin will increase, while the fluidity of the resin will reduce.

¶ Support optimization

- Increase the density and strength of support points in suspended and thin-walled areas, ensuring effective support for all parts of the model during the curing process.

- Adjust the support angle to make the contact surface of the support fit better with the model, avoiding premature detachment of the support.

¶ Resin optimization

- Check the production date and shelf life on the resin packaging.

- Observe the state of resin and check whether the color is turbid and agglomerate. If it is overdue or deteriorated. Replace the resin with new ones immediately.

- Clean the resin tank and print again for verification after the cleaning and replacement.

¶ What does it look like

¶ Issue Description: Delamination between layers

The print has obvious layered texture, inter-layer dislocation or vertical direction lines, on its surface. It reduces the surface finish and aesthetics of and may affect the accuracy of the model.

¶ How to fix

¶ Stability test

Visually inspect and manually shake the installation of the build plate/Z-axis motion mechanism (motor screw/guide rail slider, etc.) and ensure it is stable.

If there is looseness or displacement, reinsert the screws and calibrate the installation position to avoid the model lamination and staggering caused by the shaking of the mechanical structure.

¶ Appearance inspection

Scratches, deformation and other damage on the surface of the Z-axis moving mechanism parts will affect the Z-axis motion accuracy.

- Visually inspect the surface of the Z-axis moving mechanism parts.

- Replace the damaged parts with new ones.

¶ Cleaning and lubrication

Stuttering movement of the Z-axis can result in delamination between layers.

- Using a dust-free cloth with a special detergent, clean the surface of the lead screw rod and the guide rail.

- Evenly apply the lithium-based grease to the surface of the lead screw, guide rail and slider.

Note: Do not use any lubricating oil to avoid dilution of the lubrication effect or penetration.

¶ Print position and support optimization

Reasonable distribution of the support can reduce the deformation of the model during the curing process, thereby improving the problems of layer.

- Adjust the position of the model on the build plate to make the force and shrinkage direction more uniform.

- Increase the support density and strength for the parts that are prone to form layers.