¶ Description

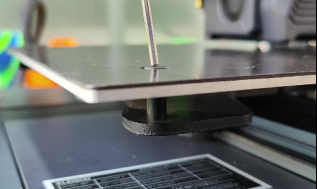

The outer layers of the model tend to lift upward, causing wave-like deformation. In some cases, the model's corner can detach from the heated bed.

Severely, the model may shift during printing, leading to interlayer misalignment or printing failure. Even if not completely detached, it may result in decreased dimensional accuracy and weakened interlayer adhesion.

¶ Reasons

¶ Lack of adhesion to the bed.

The build plate is incorrectly installed, has uneven/unclean surface, leading to insufficient adhesion of the printed model.

¶ Leveling failure.

The build plate is not leveling properly, resulting in a large distance between the nozzle and the heated bed.

¶ Improper slicing parameters.

- The heated bed temperature is set too low, and the cooling fan speed was too high, causing the model to cool down too quickly.

- The bottom line width and the number of layers are improperly set.

¶ The model’s inherent issues.

- The model's supporting structure is insufficient, or the model is too tall and has an unstable center of gravity, causing detachment from the build plate or collapse during printing.

- The model is large and has a high infill density, easily causing edge warping.

- The contact area between the model's bottom surface and the heated bed is small and the printing speed is too fast. The underlying layer will not adhere sufficiently.

¶ Low ambient temperature or excessive airflow.

The model cools down too quickly due to low ambient temperature or excessive airflow in the printing chamber.

¶ Unstable mechanical structure, such as loose printer chassis, z-axis perpendicularity deviation, and insecurely fixed heated bed, etc.

¶ Solutions

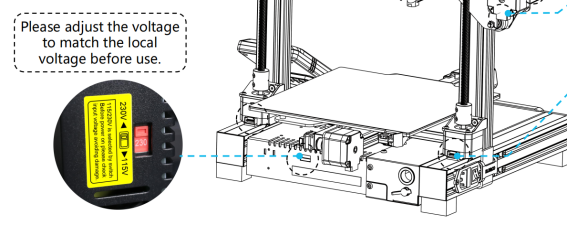

Before troubleshooting, make sure that the printer voltage is within the local applicable range. For example, 115V for the United States and Japan, and 230V for European countries such as Germany.

¶ Adjust printing temperature parameters

Before printing, make sure the heated bed temperature is stable.

Refer to the recommended printing parameter settings in the link or use the default parameters of our ELEGOO Slicer software.

NOTE: If the ambient temperature is below 20°C, the heated bed temperature should be set to +10°C or higher than usual to slow cooling between printed layers.

¶ Improve the heated bed adhesion

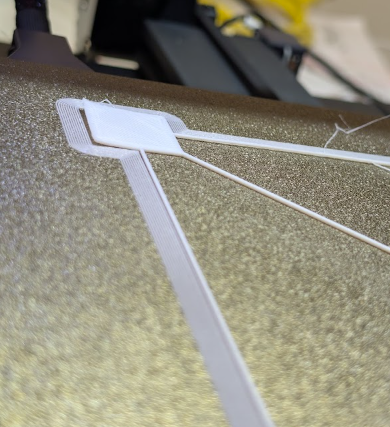

- Clean the heated bed surface. Wipe with alcohol or IPA to remove surface grease.

- Select appropriate adhesion aids.

PLA: Blue tape, PVA glue sticks, special coating

ABS: Acetone/ABS paste, PEI sheet

PETG: PEI sheet or special adhesive, etc. - Ensure the heated bed is level and adjust the height between the nozzle and the heated bed.

¶ Optimize model and slicing settings

¶ Reset the slicing parameters

- Increase the base area of the model or add supports/skirts.

- Optimize the bottom layer linewidth (120-150% of nozzle diameter), increase the number of bottom layers (2-4 layers), and reduce the printing speed (50-70% of normal speed).

- It is recommended to add rafts is recommended to improve adhesion.

- Change the infill pattern to Gyroid can reduce the risk of shrinkage.

- For structural parts requiring high strength, set 5 walls and an infill density of around 25%, avoiding infill densities above 50% to reduce filament shrinkage.

- For most non-structural parts with low strength requirements, the default 2 walls and 15% infill density can be used.

¶ Identify the optimal model orientation

Print the model at a 45° angle, or break large models down into smaller parts to avoid large areas of direct contact with the heated bed.

¶ Control the printing environment

- Avoid printing in low-temperature environments and minimize airflow in the printing area. Excessive airflow will rapidly cool the model, increasing layer adhesion tension and causing filament warping.

- When printing, you can turn off the fan for the bottom layer. If the ambient temperature is below 20°C, it is recommended to appropriately increase the heated bed temperature (+10°C) to slow down the cooling between printed layers and ensure there is no airflow around the printer.

- For materials with high shrinkage rates, such as ABS, ASA, PC, and PA, which are more prone to edge warping at high temperatures, consider using a sealed box or cover to maintain a stable printing temperature.

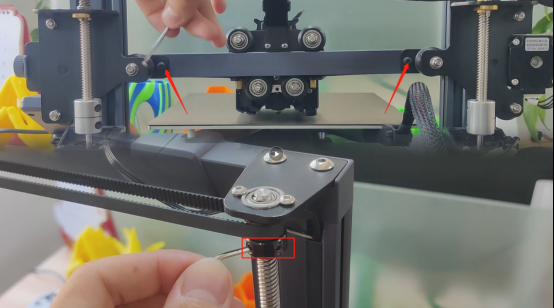

¶ Maintain a stable mechanical structure

-

Check the connectors and screws of the printer.

After long-term printing, the connectors and screws of the printer will become loose, which may cause high-frequency vibrations during printing. Then, the relative position of the nozzle and heated bed will fluctuate, and the first layer will be uneven.

-

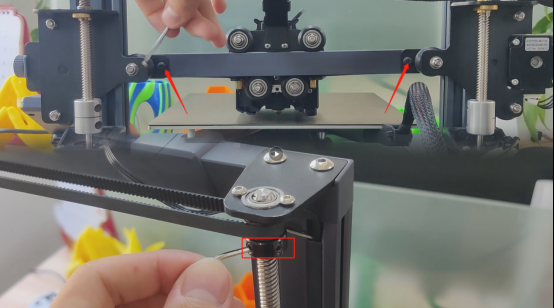

Make sure that the z-axis is perpendicular to the heated bed, and the lead screw and shaft is parallel.

-

Make sure that the heated bed screws are secured and the heated bed support structure are rigid.

-

Make sure that the timing belts are secured and the guide rail are lubricated.

-

Make sure that the stepper motor works normally.

Stepper motor driver issues. Insufficient motor torque or improper drive current settings cause step loss, or a loose motor fixation causes additional vibration, resulting in interlayer misalignment and reduced adhesion of the underlayer. -

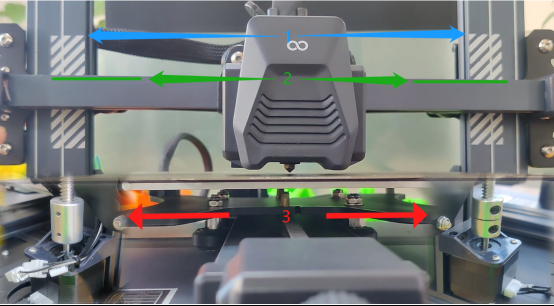

Make sure that the print head is rigid.

Insufficient rigidity of the print head support, such as aging of plastic parts or deformation of metal parts causes the print head to shift laterally or vertically during high-speed movement. This can result in decreased printing accuracy of the first layer and warping of the edges.