¶ Description

The gears vibrate only slightly and fail to engage the filament properly, which prevents it from being delivered to the nozzle. This results in issues such as filament breakage and missing layers of the print.

¶ Reasons

- The filament guide tube has bending or damage.

- The hose tube or nozzle is clogged.

If you encounter significant resistance, loosen the pressure roller and manually pull the consumable. Try to pull the filament without holding the roller, if there is significant resistance, it indicates that the hose tube or nozzle is clogged. - The extruder cable is loose or the port is installed correctly.

- The extrusion gear has mechanical failure.

¶ Solutions

¶ Step 1 Check the filament guide tube for deformation and foreign objects.

If the guide tube is bent, attempt to straighten it. If it cannot be straightened or repaired, replace it with a new feed tube.

If there is any debris or foreign objects inside the tube, use an air gun or drain cleaner to remove the debris. Additionally, wipe the inner walls to ensure unobstructed flow.

You can also refer to official guidelines: https://youtu.be/pnRTHs4xE50.

¶ Step 2 Clean the nozzle.

You can refer to the official methods for troubleshooting, cleaning, and replacement: https://youtu.be/DfXCMzTMSAY.

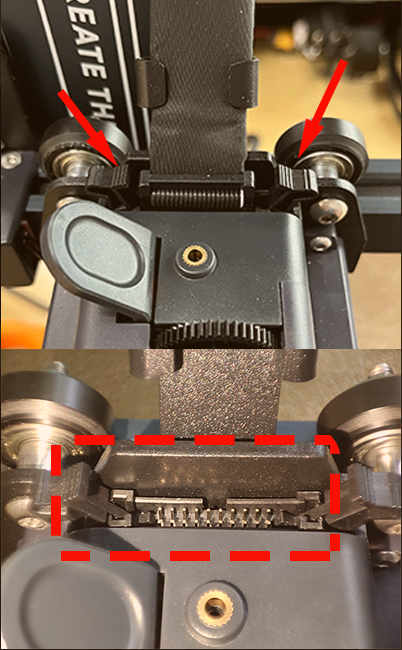

¶ Step 3 Replug the cable and inspect the cable port.

If the cable is damaged, it must be replaced with a new cable assembly.

If the cable port pins are damaged, a new adapter board will need to be replaced.

You can refer to the official guidelines for troubleshooting, cleaning, and replacement methods: https://youtu.be/E9sx8Lj4zmA .

¶ Step 4 Inspect the gear and motor shaft.

- Clean any debris from the gear teeth. If you find any cracks, missing teeth, or severe wear, the gears must be replaced immediately.

- Unscrew the set screws and check the fit between the gear and the motor shaft. If it is loose, realign the components and tighten the set screws.

You can refer to the official guidelines for troubleshooting, cleaning, and replacement methods: https://youtu.be/7dGtYT3cMIY.

- Replace the pressure roller as soon as it shows signs of wear.

To adjust the pressure, rotate the roller clockwise to increase pressure and counterclockwise to decrease it. The ideal pressure should allow the consumables to mesh smoothly, providing a slight resistance.

¶ Step 5 Investigate additional related factors.

- Confirm the filament specification.

Make sure that the filament size is 1.75mm, as a larger size may cause feed jamming. - Verify that the type of consumable matches the set printing temperature.

If the temperature is too low, increase it as necessary. - Confirm the firmware parameter.

If the firmware or printing configuration parameters have been recently updated or modified, it is recommended to restore the default settings or re-flash the compatible firmware.

https://www.elegoo.com/pages/download

If the issue still occurs, reach out to the ELEGOO after-sales technical team. When you contact them, make sure to include the results of your troubleshooting efforts and a clear photo of the motherboard.

The ELEGOO technical team will review the information you provide and will work to offer a solution.