¶ Issue Description

The filament fails to be fed from CANVAS to the tool head.

¶ Reasons

-

The filament are knotted or tangled.

-

The feeding of CANVAS channels has abnormality.

-

The filament runout sensor at the tool head is abnormal.

-

Filament is not inserted normally in non-printing state.

¶ Troubleshooting Steps

¶ Tools needed for troubleshooting

-

A 1.5 mm Allen key

-

A 2.0 mm Allen key

-

A 2.5 mm Allen key

¶ Step 1 Check the channel with the flashing red light of CANVAS and observe whether the filament in the corresponding channel have been knotted or tangled.

¶ Step 2 If the filament is not tangled or knotted, continue to check whether there is filament residue inside the bottom bracket assembly.

Note: If there is residual filament inside the 4-in-1 hub and the filament detection board is not triggered, it may cause the filament entering the other channels to be fed abnormally.

-

Turn the power switch OFF (symbol "〇") and unplug the power cord.

-

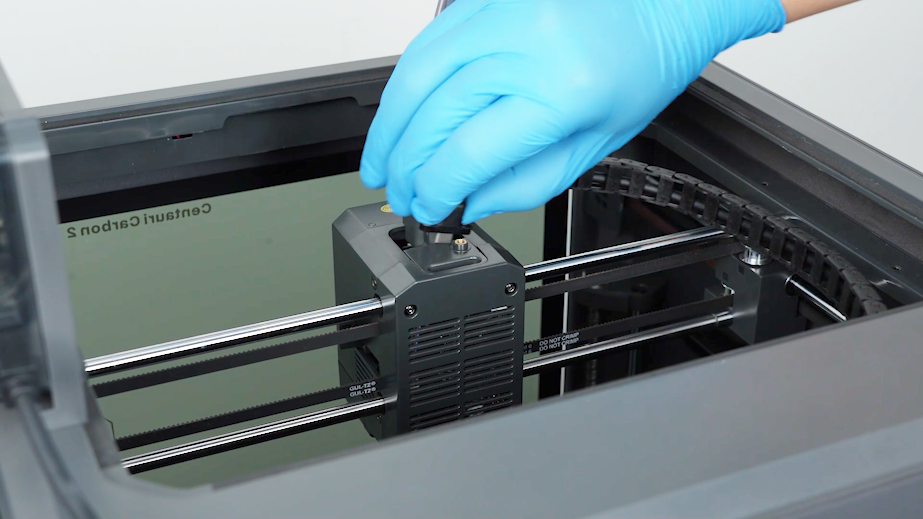

Remove the cover.

-

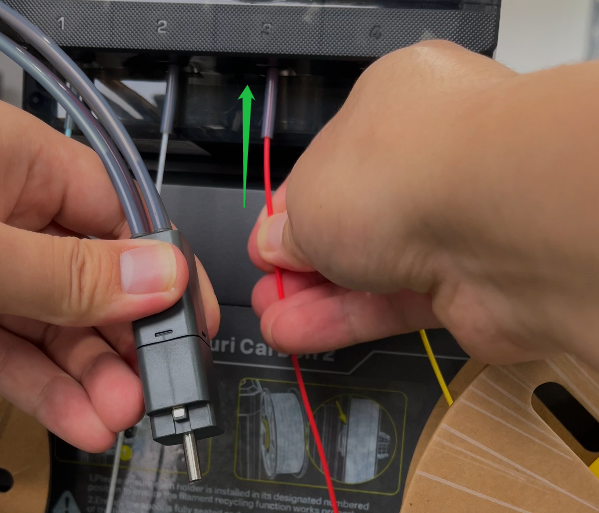

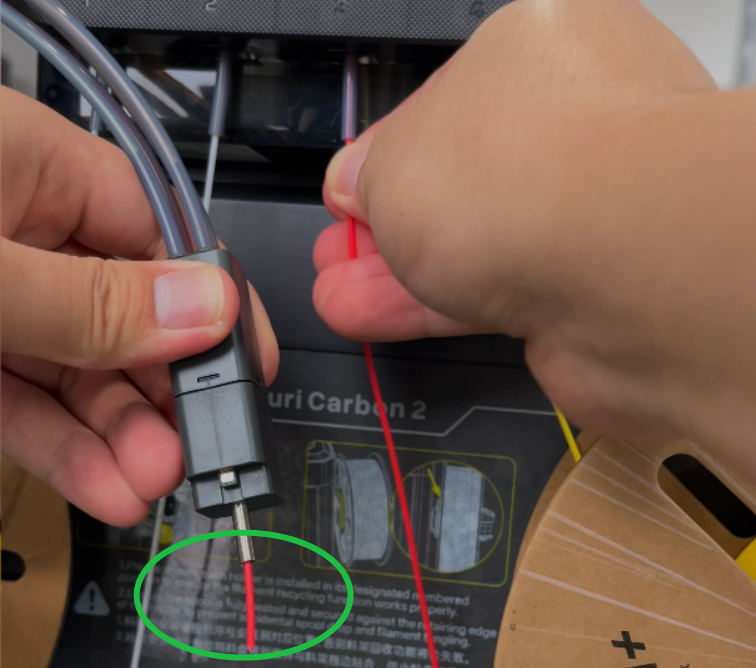

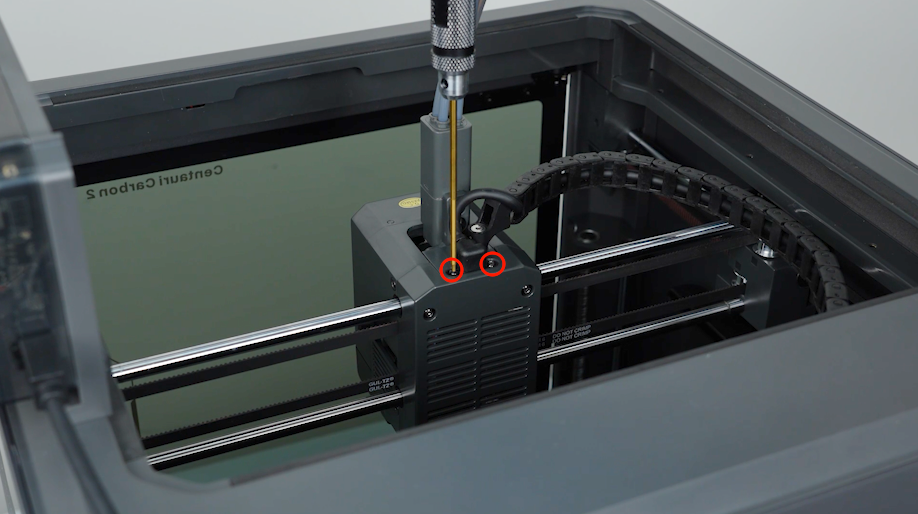

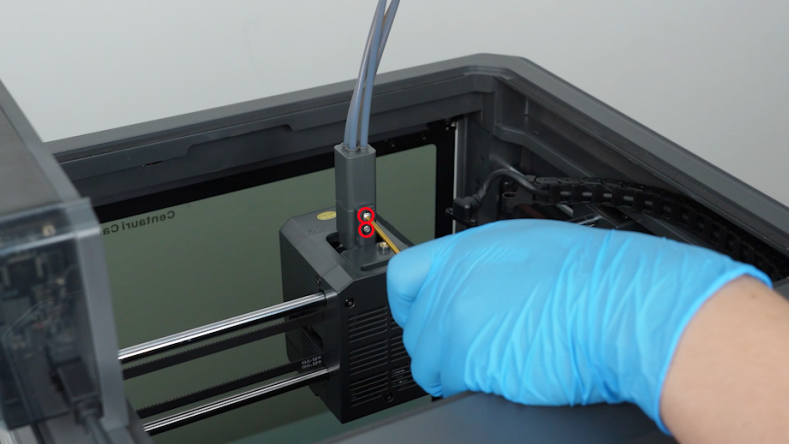

Loosen and remove the two screws securing the extruder communication cable with a 1.5 mm Allen key.

-

Loosen the screws securing the tank chain and unplug the extruder communication cable with a 2.5 mm Allen key.

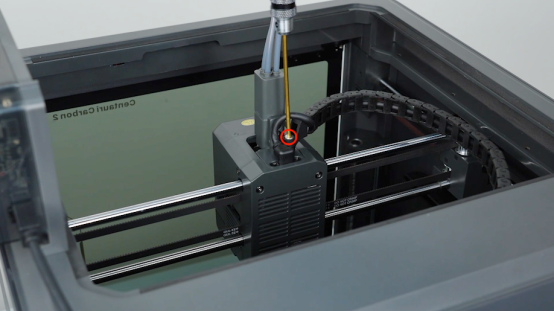

-

Loosen the two screws securing the 4-in-1 hub and remove the 4-in-1 hub with a 2.0 mm Allen key.

-

Push the filament manually. Check whether the filament can be pushed out from the 4-in-1 hub and whether any residual filament is left in the 4-in-1 hub.