¶ Issue Description

The filament fails to be extruded from the tool head.

¶ Reasons

-

The filament is tangled and knotted.

-

The filament is disconnected between the 4-in-1 hub and CANVAS.

-

The nozzle is clogged.

¶ Troubleshooting Steps

¶ Tools needed for troubleshooting

-

A 1.5 mm Allen key

-

A 2.5 mm Allen key

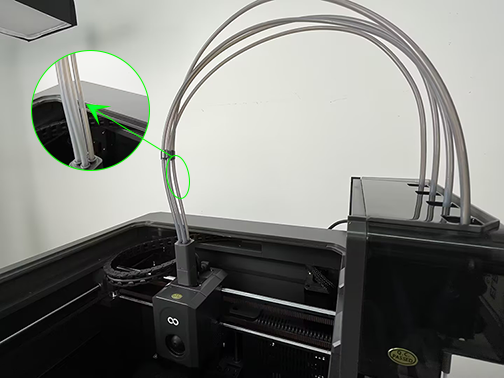

¶ Step 1 Check the filament spool and the PTFE tube.

-

Check whether the filament has tangles or knots at the spool of the corresponding channel.

-

Pull out manually the filament from the abnormal channel of the CANVAS. Check whether any filament is broken in the PTFE tube.

¶ Step 2 Check the 4-in-1 hub.

-

Turn the power switch OFF (symbol "〇") and unplug the power supply cable.

-

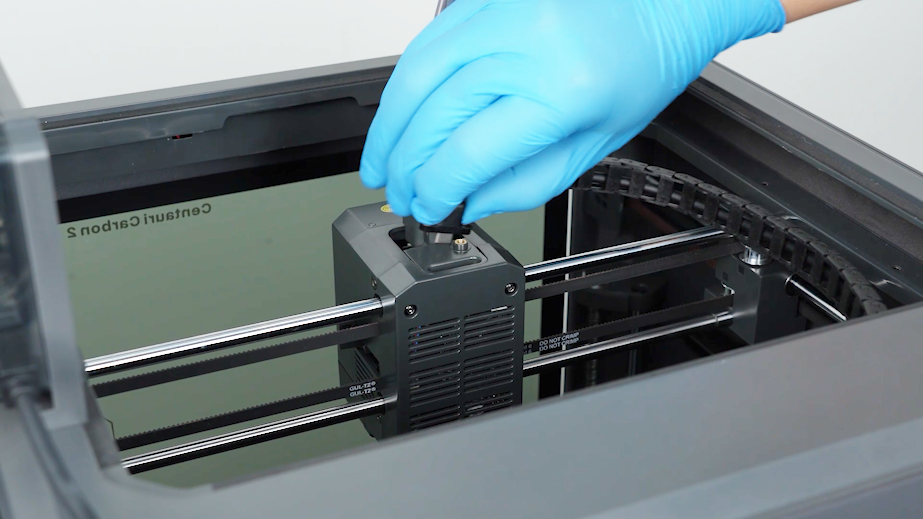

Remove the lid.

-

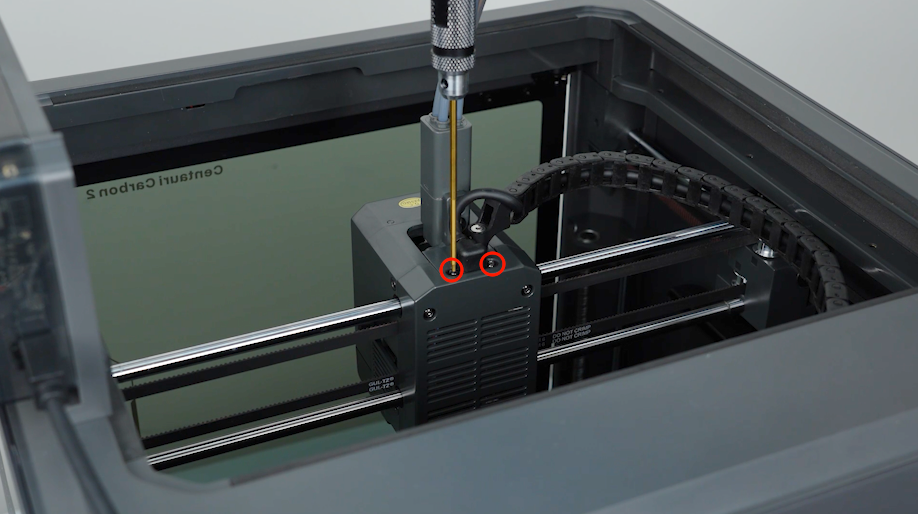

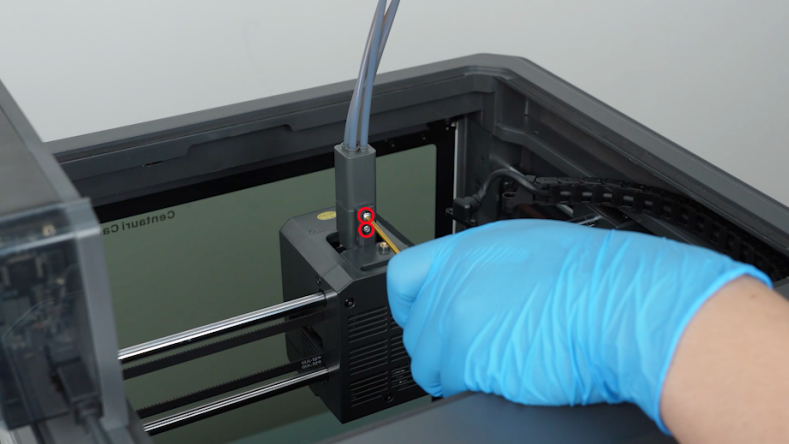

Loosen and remove the two screws securing the extruder communication cable with a 1.5 mm Allen key.

-

Loosen the screws securing the tank chain with a 2.5 mm Allen key and unplug the extruder communication cable.

-

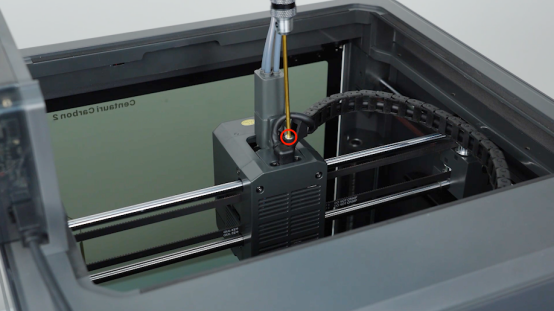

Loosen the two screws securing the 4-in-1 hub and remove the 4-in-1 hub with a 2.0 mm Allen key.

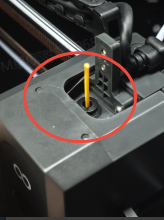

- Check the tool head for any broken filament.

- If the filament breaks in the tool head, manually pull out the filament.

¶ Step 3 Check whether the nozzle is clogged.

-

If there is no filament broken inside, insert a filament into the 4-in-1 hub.

-

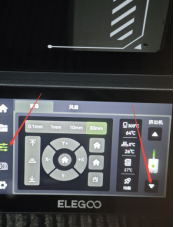

On touch screen, heat up the nozzle and select Load.

-

Check the filament extrusion at this time. If it cannot be extruded normally, it indicates that the nozzle is clogged.

-

Set the nozzle temperature to 200 °C on the touch screen and clear the nozzle with an unclogging tool.

Note: Do not touch the nozzle during operation to avoid burns.