¶ Tools and Materials

- A 2.5 mm Allen key

- A pair of pincers

- A cleaning needle

¶ Tutorial Video

Coming soon.

¶ Instruction

- Power off the printer and unplug the power cord.

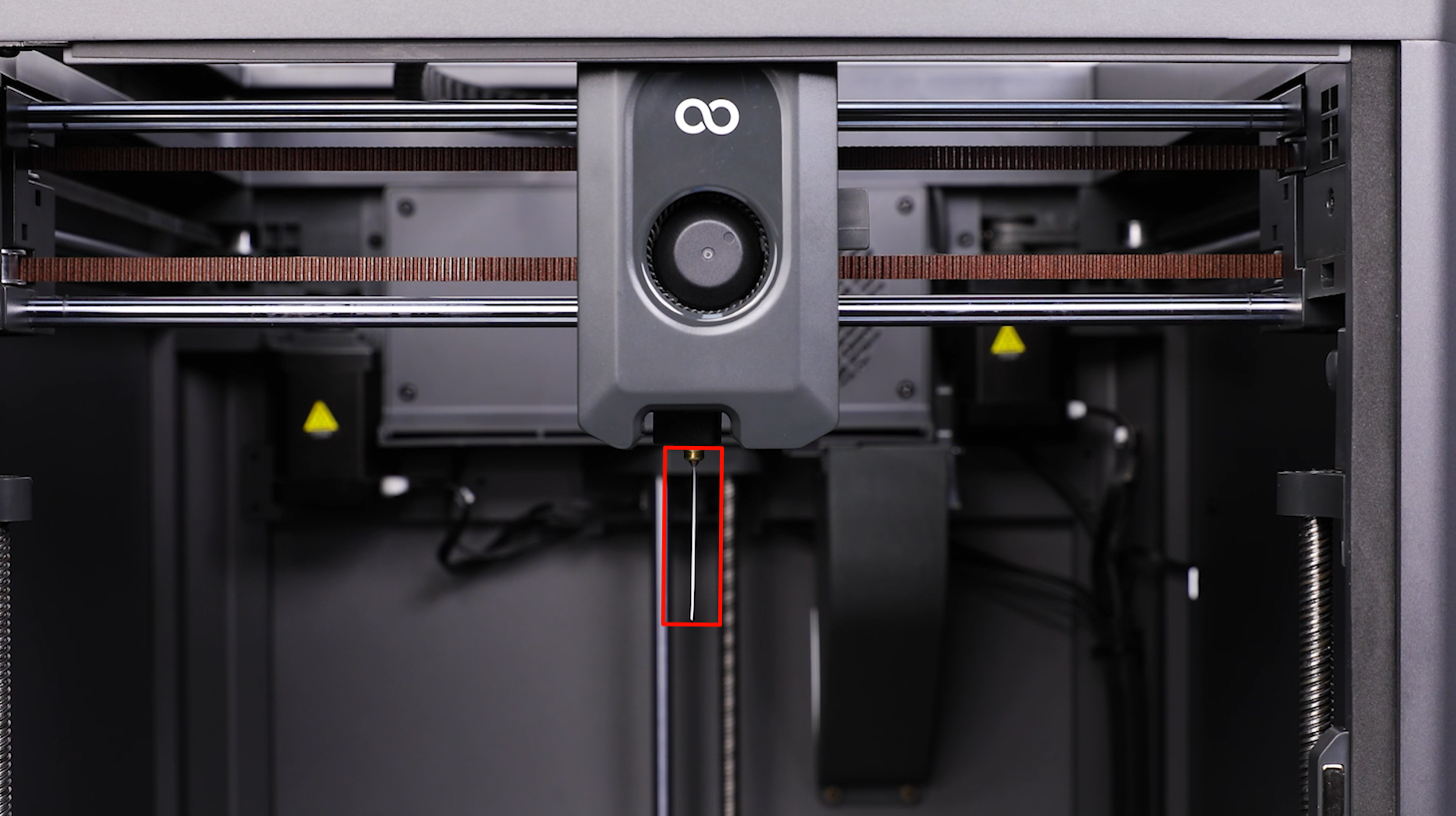

- Press the lever of the filament cutter backward to cut off the filament.

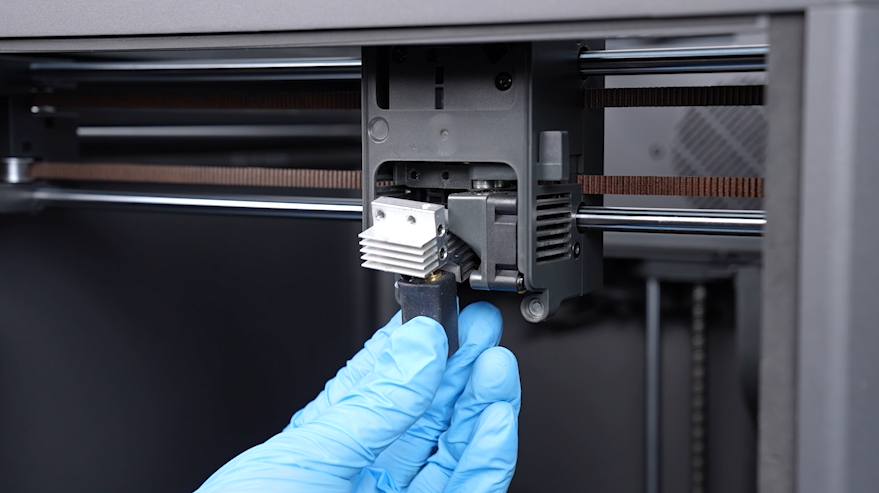

- Lift the front cover of the printing head to remove it. Unplug the port of the ribbon cables of the model cooling fan.

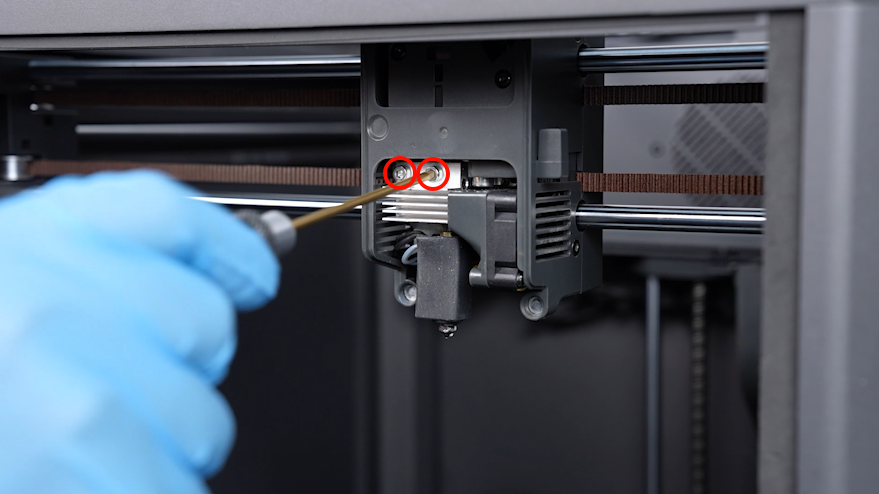

- Use a 2.5 mm Allen key to loosen the 2 screws securing the nozzle assembly, then remove the nozzle assembly.

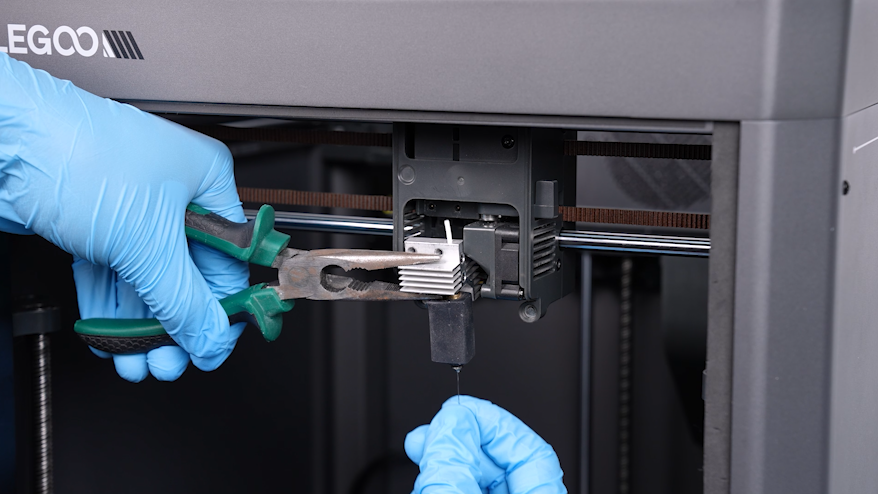

- Power on the printer. Holding the nozzle assembly with a pair of pincers, navigate to "Function" on the touchscreen to enter the Prepare interface. Set the temperature of the nozzle to 220 ℃.

Note: The pair of pincers should be clamped at the upper heat sink block position to avoid damaging the heating plate.

- Insert the cleaning needle into the nozzle and push the residual filaments out. Remove the residual filaments above the nozzle assembly. Push the needle in and out 3 to 5 times to ensure that the nozzle has been cleaned thoroughly.

- Insert a piece of filament into the nozzle assembly. Observe that the nozzle can extrude the filament successfully, then remove the filament.

- Set the temperature of the nozzle to 0 ℃. Wait about 5 to 10 minutes for the nozzle to cool down completely.

- Put the nozzle assembly in the installation position by aligning it the the screw holes. Use a 2.5 mm Allen wrench to tighten the 2 screws securing the nozzle assembly.

- Prepare the front cover of the printing head. Plug in the port of the ribbon cables of the model cooling fan.

- Organize the ribbon cables of the model cooling fan. Put the front cover of the printing head in the installation position by aligning it positioning holes.

- Set the temperature of the nozzle to 220 ℃. Navigate to "Extruder" and observe the filament being extruded from the nozzle. The printer can work as usual after being re-leveled.